Controller for internal combustion engine

A technology for internal combustion engines and control equipment, which is applied in engine control, mechanical equipment, machines/engines, etc. It can solve problems such as the failure to realize the driver's vehicle action, achieve improved control response characteristics and control stability, eliminate response delays, and improve control Effects of Response Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

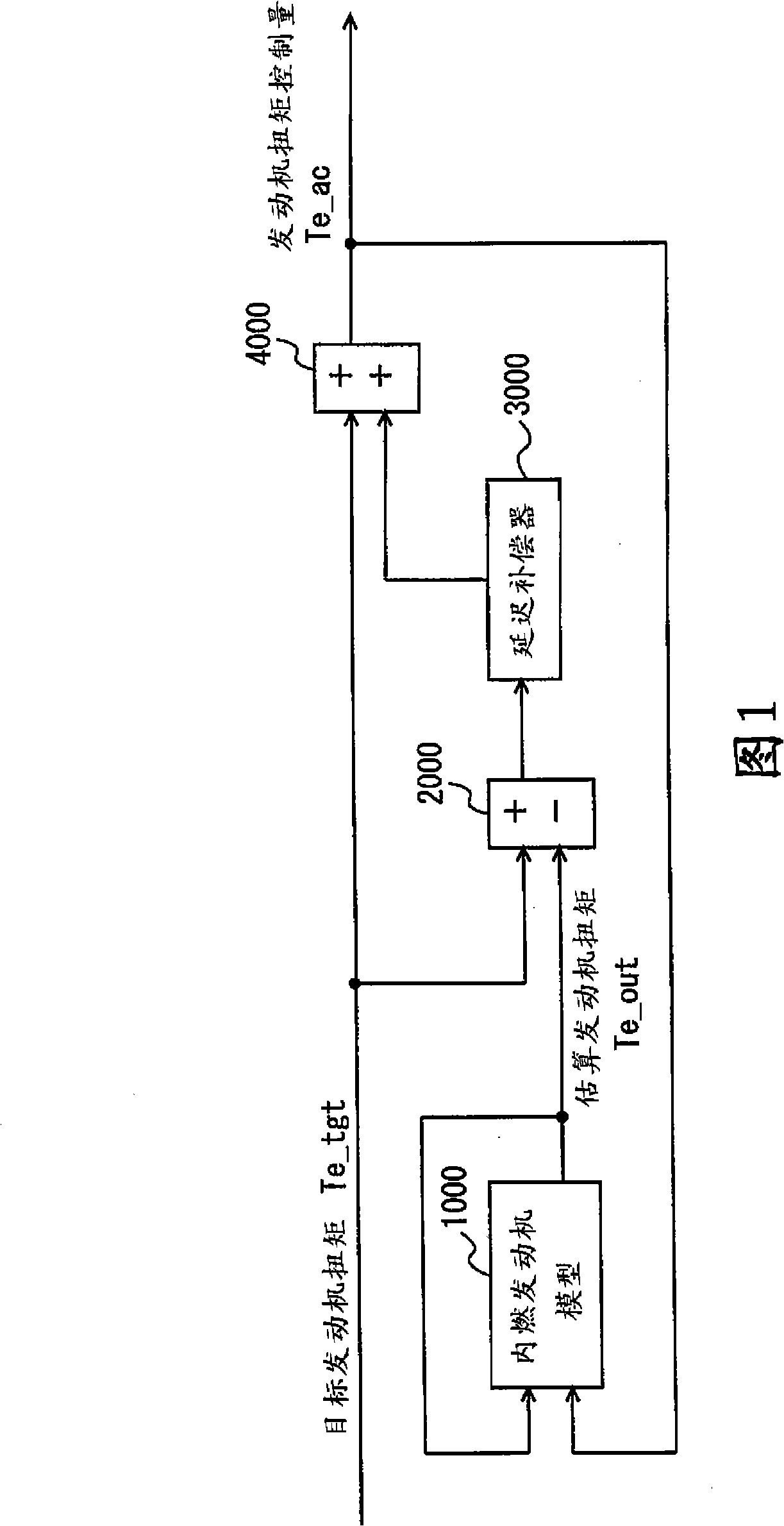

[0042] The driving force control system according to the present embodiment aims at improving response characteristics. When calculating the engine torque control amount for realizing the target engine torque, the drive force control system compensates for the control response delay based on the difference between the estimated engine torque estimated from the target engine torque control amount and the target engine torque. Calculate target engine torque. Therefore, it is possible to calculate the control amount that has correctly compensated for the control response delay. Here, the internal combustion engine model used to calculate the estimated engine torque is assumed to be a linear model, excluding dead time, thereby facilitating execution on an ECU (Electronic Control Unit).

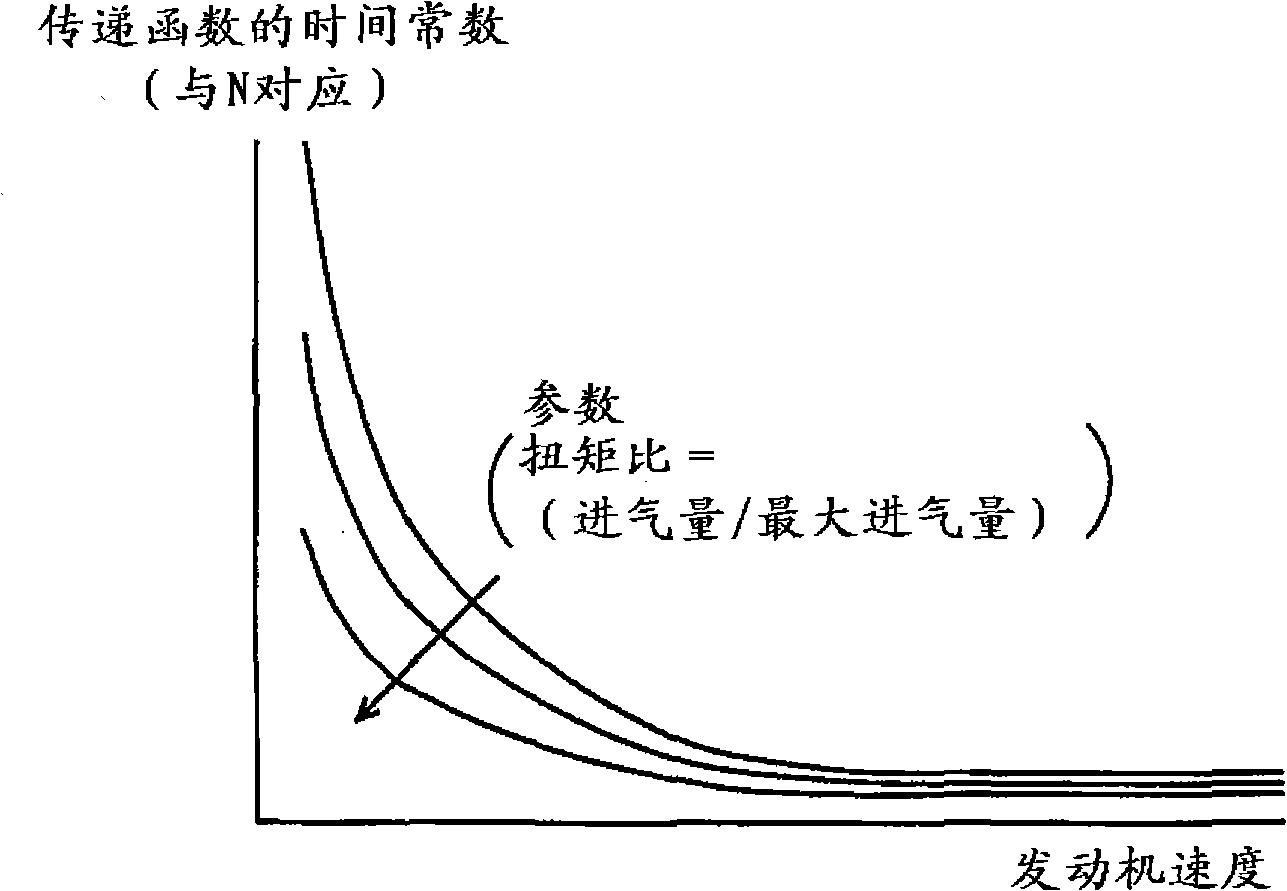

[0043] A control block diagram of the driving force control system according to the present embodiment will be described below with reference to FIG. 1 . It should be noted that the transfer fun...

no. 2 approach

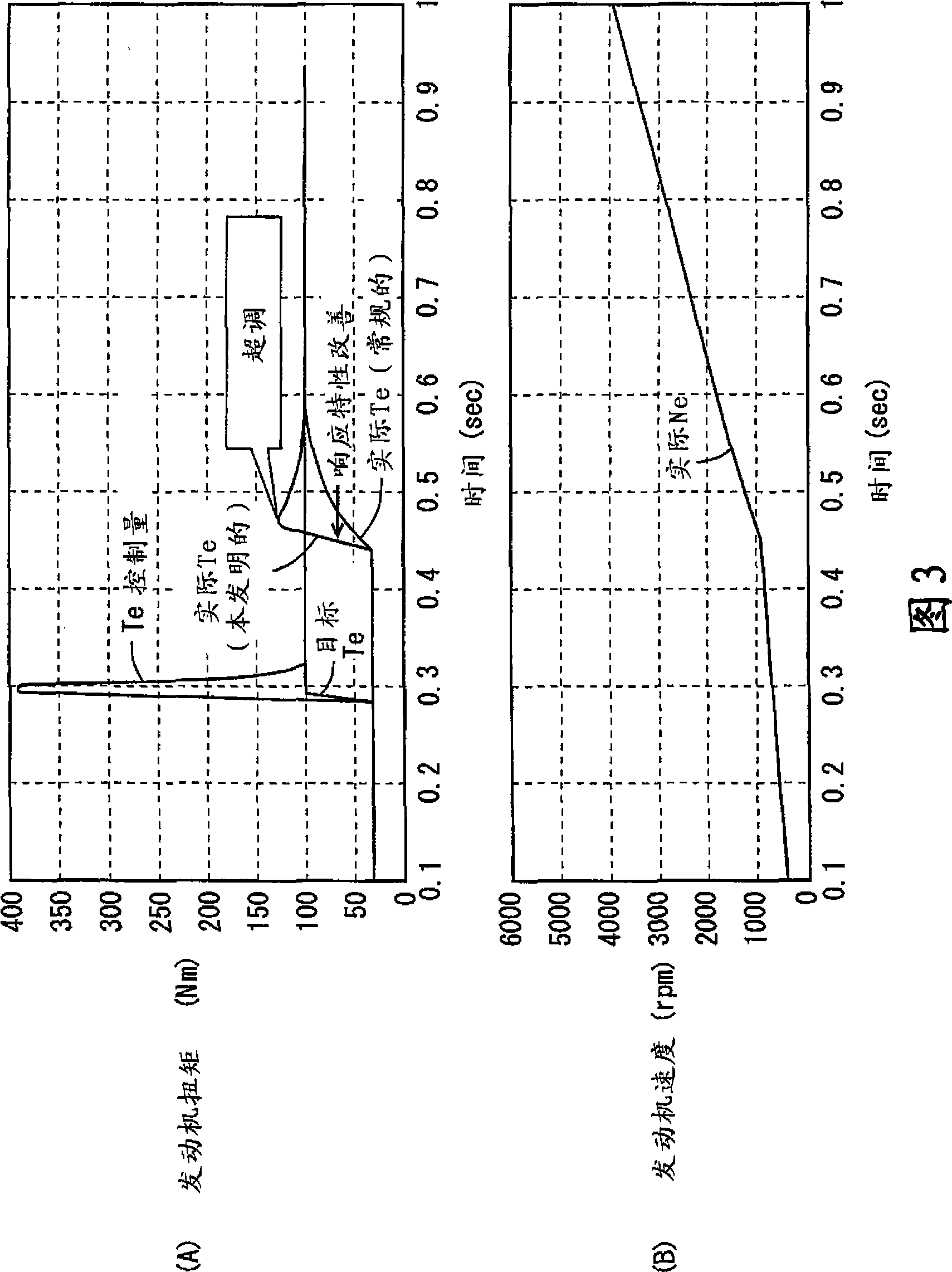

[0065]A driving force control system according to a second embodiment of the present invention will be described below. The driving force control system according to the present embodiment is intended to avoid overshoot due to the dead time of the internal combustion engine. In the driving force control system according to the first embodiment described above, since the transfer function of the internal combustion engine includes a dead time component, the transfer function of the internal combustion engine at the time of calculating the engine torque control amount is different from the transfer function at the time of executing the torque control amount. Different, so overshoots such as overshoot and undershoot occur. Thus, the behavior of the vehicle is disturbed.

[0066] Therefore, in the driving force control system according to the present embodiment, in consideration of the dead time of the internal combustion engine, the engine torque control amount based on the esti...

no. 3 approach

[0100]Delay compensation or dead time compensation in addition to delay compensation is performed in the above-described embodiments. That is, this compensation is performed (compensation is performed by multiplying the deviation between the estimated actual output value and the target value by a gain to obtain a control amount, thereby compensating for delay and dead time). If such compensation is performed without exception for a small change in the target value, an actuator such as an electronic throttle valve that adjusts an intake air amount will oscillate to reduce durability. In particular, even when feedback control is being performed and a steady state is reached (basically, when there is no change in driving force required by the driver or a vehicle control system such as cruise control), the calculated target value is constantly changing. Usually, this variation is small and the response characteristics of this variation are not problematic. Therefore, in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com