Method and equipment for producing polyphosphoric acid with wet process phosphoric acid

A technology of polyphosphoric acid and wet-process phosphoric acid, applied in phosphorus oxyacid, condensed phosphoric acid, lighting and heating equipment, etc., can solve the problems of easy corrosion, easy overheating and difficult purification of equipment, saving energy and reducing exhaust gas emissions , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

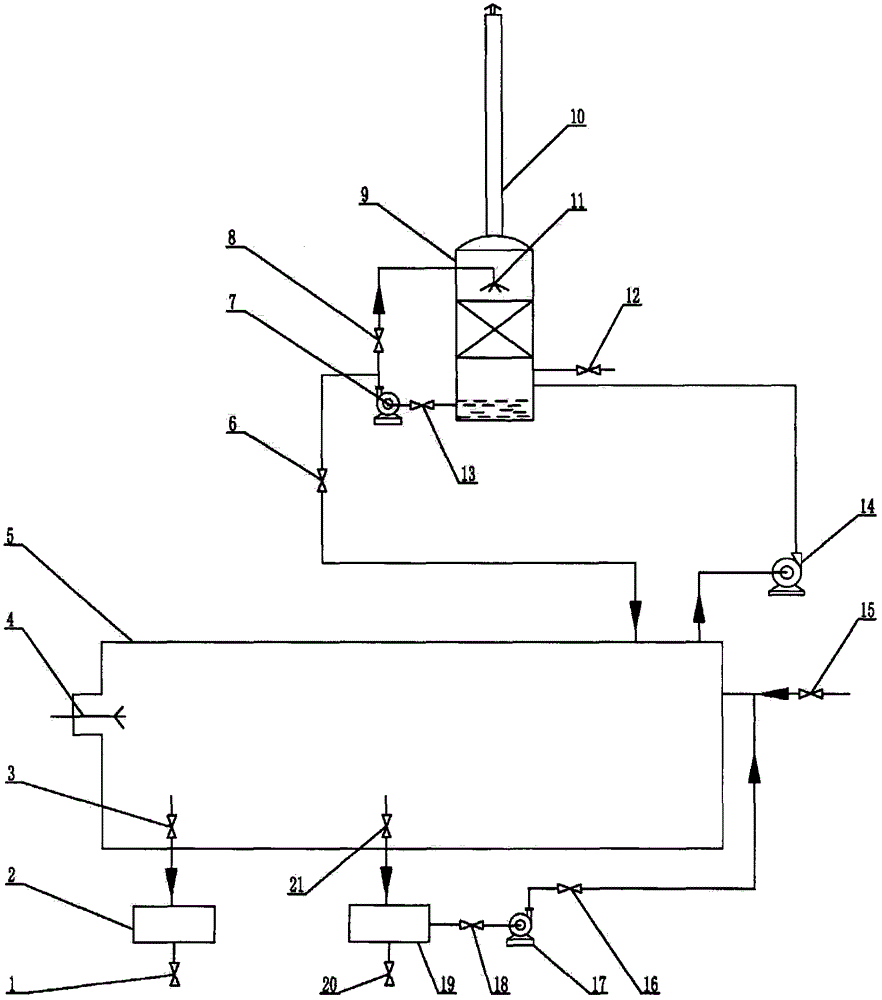

[0029] The implementation steps of the present invention will be further described in detail below in conjunction with the above-mentioned drawings and specific embodiments, so as to facilitate a clearer understanding of the purpose, technical solutions and advantages of the present invention. It is necessary to point out here that the specific examples described below are only used to further illustrate the present invention, and should not be interpreted as limiting the protection scope of the present invention. Essential improvements and adjustments, or replacement of some equipment with similar equipment, examples are as follows:

[0030] The first step is to open the connection valve between the liquefied gas pipeline and the burner 4, supply gas to the burner 4 and ignite it to heat up the reverberatory furnace;

[0031] In the second step, add water to the packed washing tower 9 through the control valve 12 to a position 70 cm above the inlet of the control valve 13, op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com