Low current velocity fluidize cleaning type horizontal column pipe heat transfer equipment system

A technology of heat transfer equipment and low flow rate, which is applied in the field of low flow rate fluidized cleaning type horizontal tube heat transfer equipment system, which can solve the problems of high equipment cost, high flow rate requirements, and difficult cleaning of hard scales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention will be described in further detail below in conjunction with the accompanying drawings.

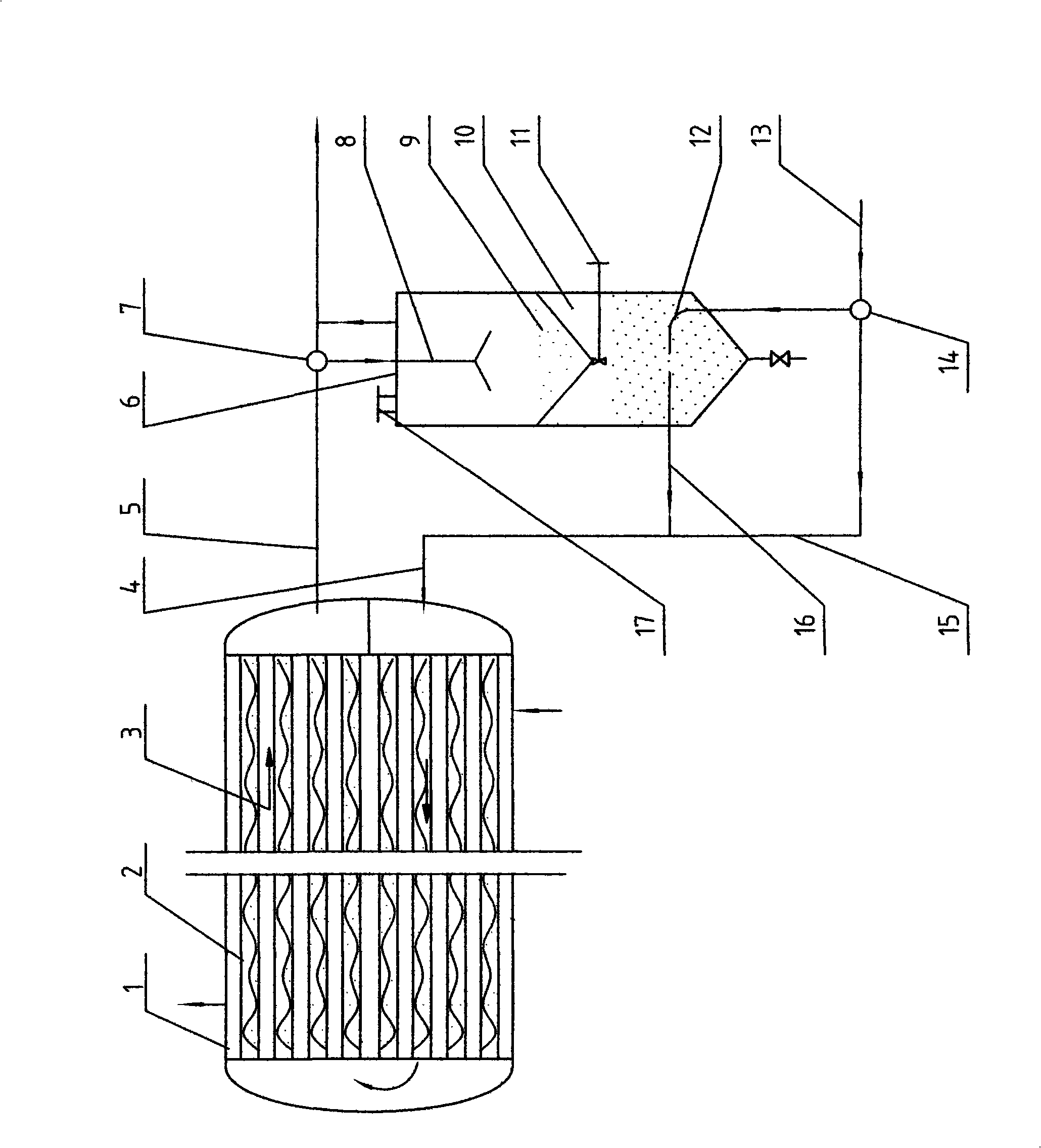

[0007] In the figure 1 heat transfer equipment 2 heat transfer pipe 3 spiral line 4 inlet pipe 5 outlet pipe pipeline 6 circulation tank 7 three-way valve 8 upper part 9 particles 10 lower part 11 communication valve 12 fluidized liquid preparation pipe 13 liquid inlet pipe 14 three-way Valve 15 Clear liquid pipe 16 Fluidized liquid pipe 17 Particle replenishment port

[0008] A low flow rate fluidized cleaning type horizontal tube heat transfer equipment system, a helix 3 is arranged in the heat transfer tube 2 of the heat transfer equipment 1, the length of the helix 3 is roughly equal to the length of the heat transfer tube 2, and the helix 3 The size of the coil is mainly designed according to the requirements of heat transfer enhancement and fluid resistance. The diameter d of the helix 3 can be in the range of 1 to 6 mm, and the pitch T and the inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com