Motor control apparatus of elevator

A technology of control devices and motors, which is applied to elevators, lifts, transportation and packaging in buildings, and can solve problems such as time-consuming and labor-intensive, unclear constants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

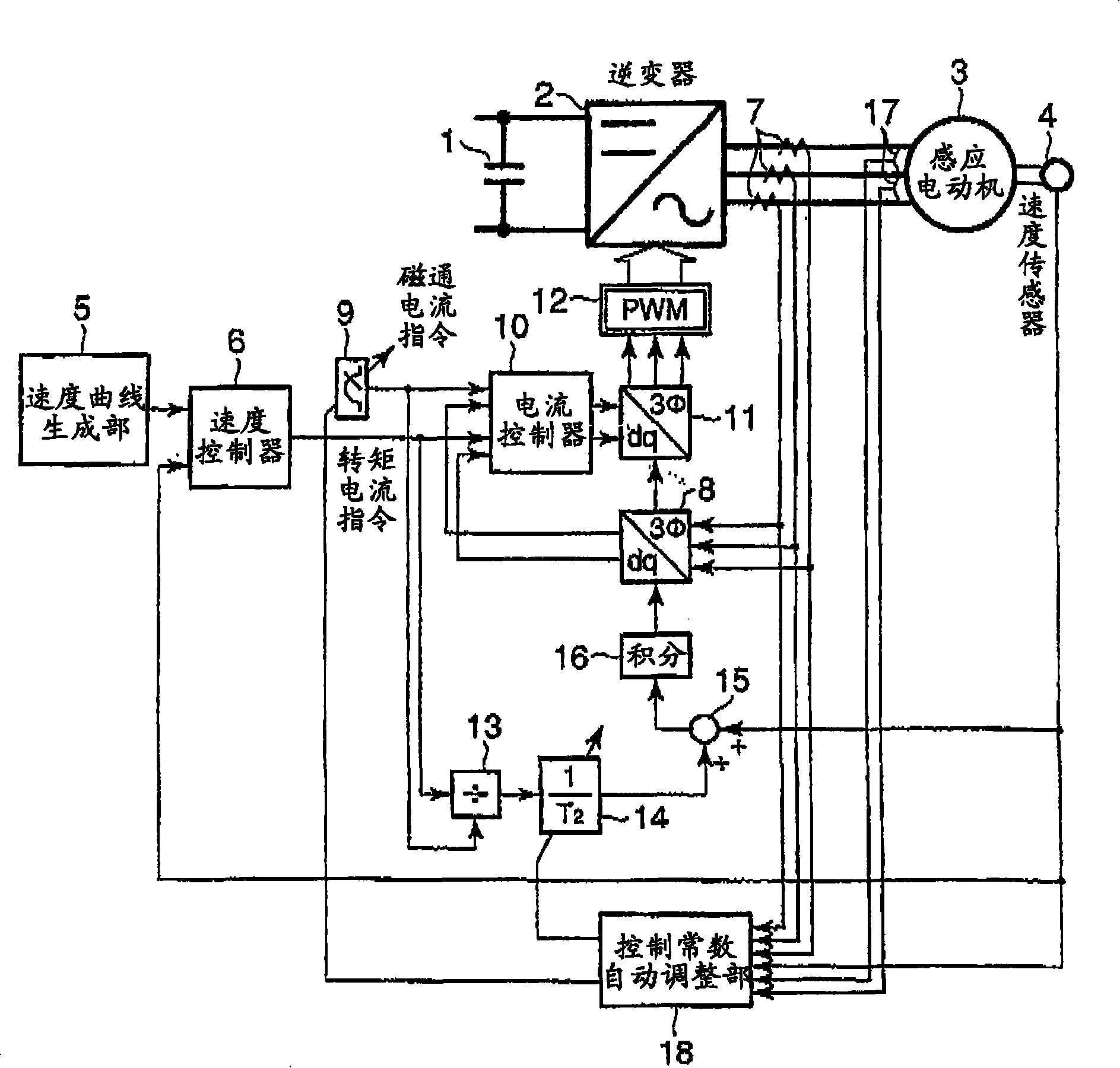

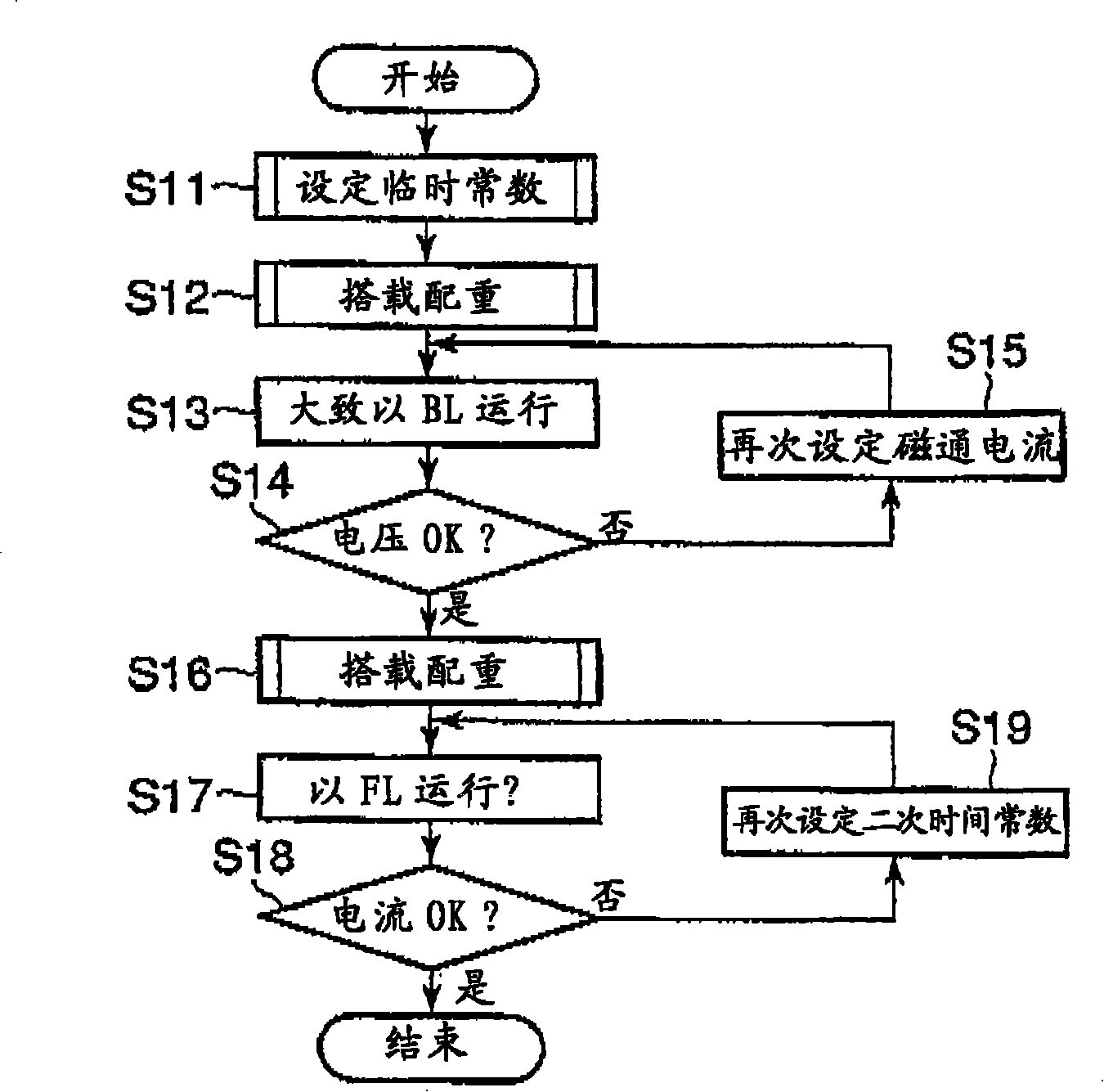

[0036] figure 1 It is a diagram showing the system configuration of the motor control device using the vector control method according to the first embodiment of the present invention.

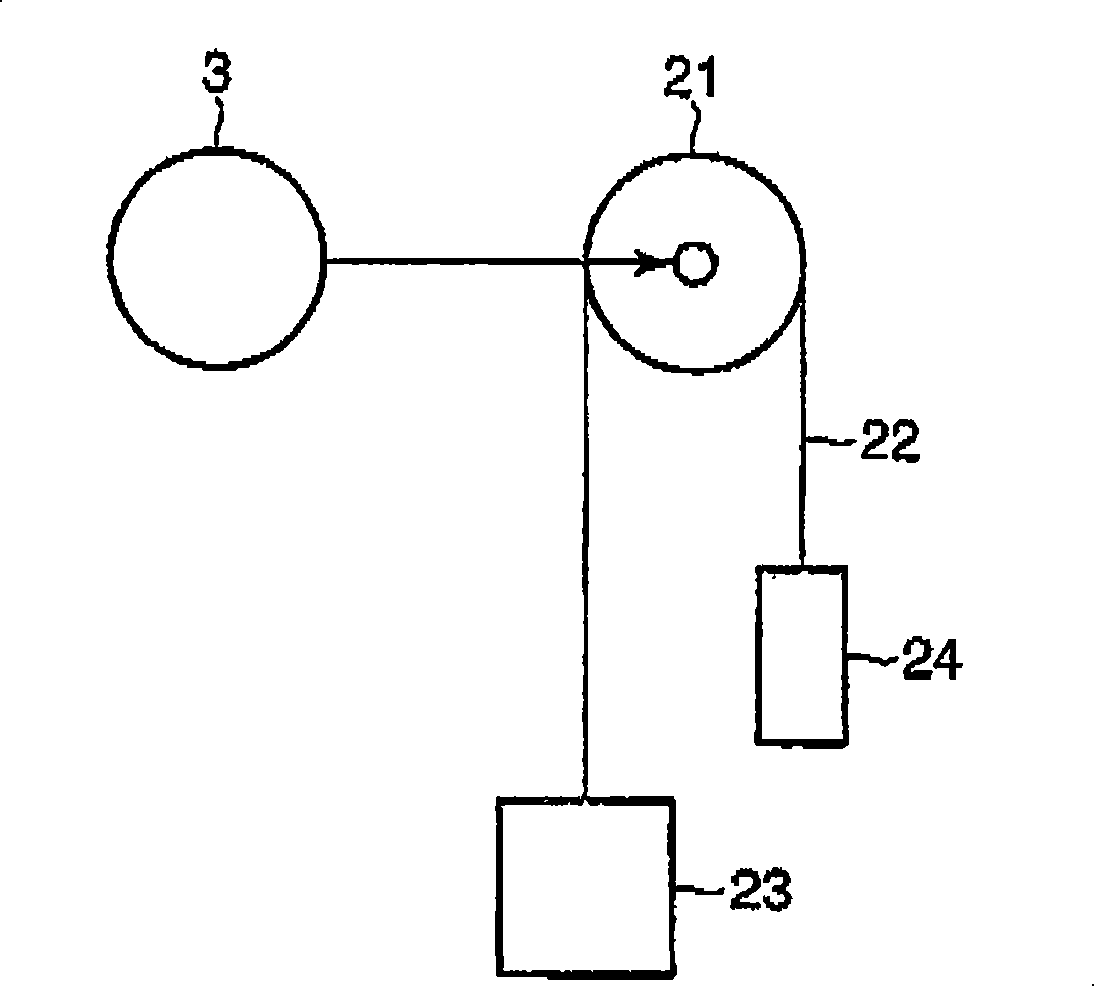

[0037] In this motor control device, an inverter 2 converts a DC voltage obtained by a DC power supply 1 such as a rectifier into AC power with a variable frequency and a variable voltage to drive an induction motor 3 . Such as figure 2 As shown, the hoisting machine 21 of the motor is directly connected to the induction motor 3 . When the induction motor 3 is driven, the winch 21 rotates with it, and the car 23 and counterweight 24 of the elevator go up and down in the hoistway like a bucket through the steel cable 22 wound on the winch 21 .

[0038] When the induction motor 3 is driven, the rotational speed of the induction motor 3 is detected by the speed sensor 4 . The rotational speed of the induction motor 3 detected by the speed sensor 4 is input to a speed controller 6 composed of ...

no. 2 approach

[0071] Next, a second embodiment of the present invention will be described.

[0072] The composition of the second embodiment and figure 1 The same, only the role of the control constant automatic adjustment unit 18 is different. That is, in the first embodiment, it is necessary to adjust the weight to achieve the BL state, and the operator performs this adjustment. On the other hand, in the second embodiment, the control constant automatic adjustment unit 18 is configured to automatically calculate the weight for setting the BL state, and to instruct the operator.

[0073] Specifically, the elevator is operated with a temporary vector control constant in an unloaded state (no load state), and the average power consumption P in the constant-speed operation section is obtained by the control constant automatic adjustment unit 18. AVE . In addition, hereinafter, the state in which the car 23 is empty is simply referred to as an NL (No Load) state.

[0074] Average power con...

no. 3 approach

[0099] Next, a third embodiment of the present invention will be described.

[0100] The configuration in the second embodiment mode, and figure 1 They are the same, but the function of the control constant automatic adjustment unit 18 is different. That is, in the first embodiment, when updating the value of the secondary time constant reciprocal setter 14 according to the current value in the FL state, the average value of the torque component current, theoretically speaking, in the up running and down running Runtimes should be equal in absolute value, opposite only in polarity. However, there are cases where the absolute values of both are different due to mechanical friction loss, the weight of the wire rope, and the like.

[0101] Therefore, in the third embodiment, as the torque current average value I qAVE Absolute value, take up run / down run respective I qAVE The average of the absolute values, the polarity is the same as that used for the uplink operation. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com