Local exhaust apparatus

An exhaust system, local technology, applied in airflow control components, household heating, space heating and ventilation details, etc., can solve the problems of increasing the total number of local exhaust system components, high maintenance costs, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Reference will now be made in detail to various embodiments of the invention, examples of which are illustrated in the accompanying drawings and the description below.

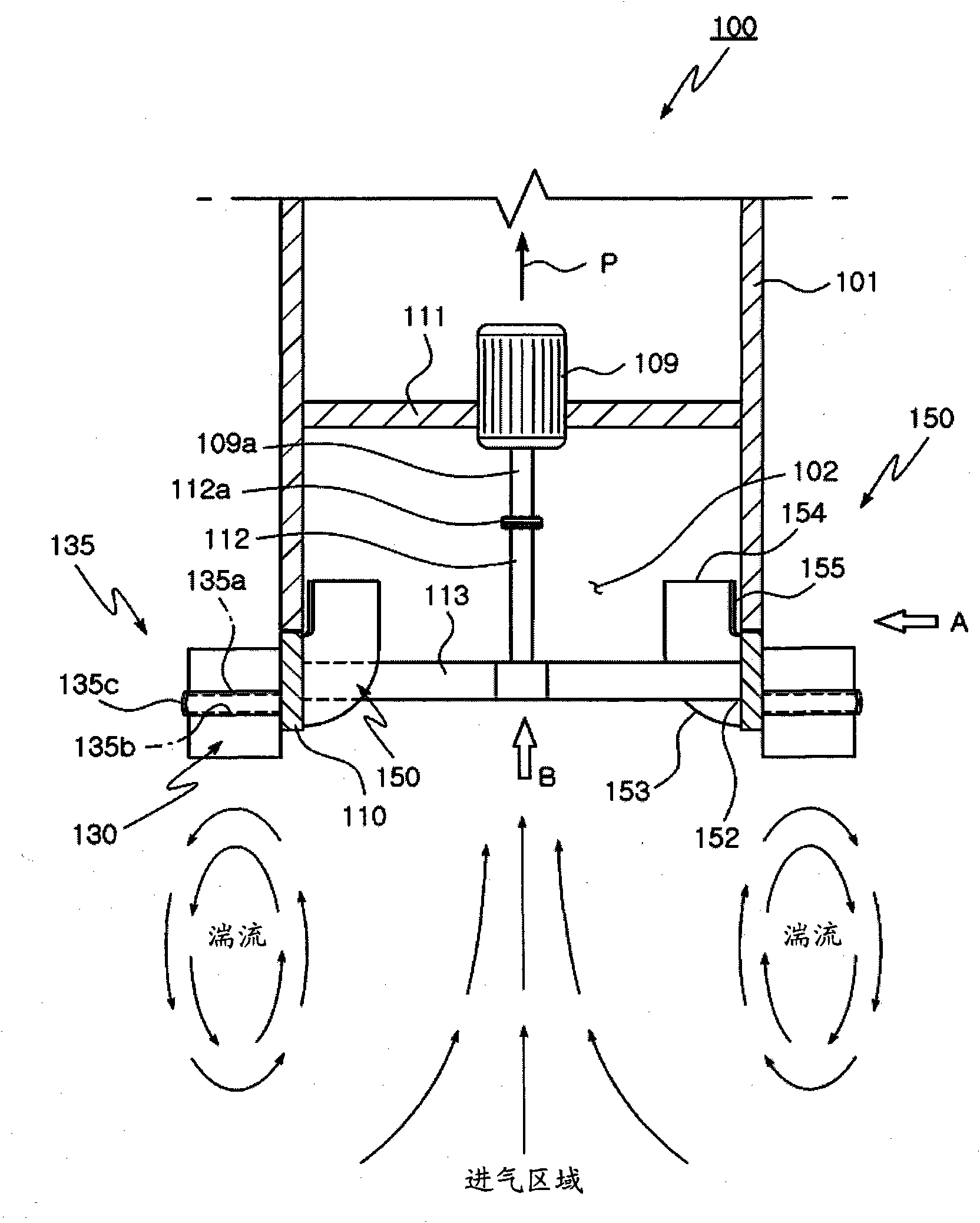

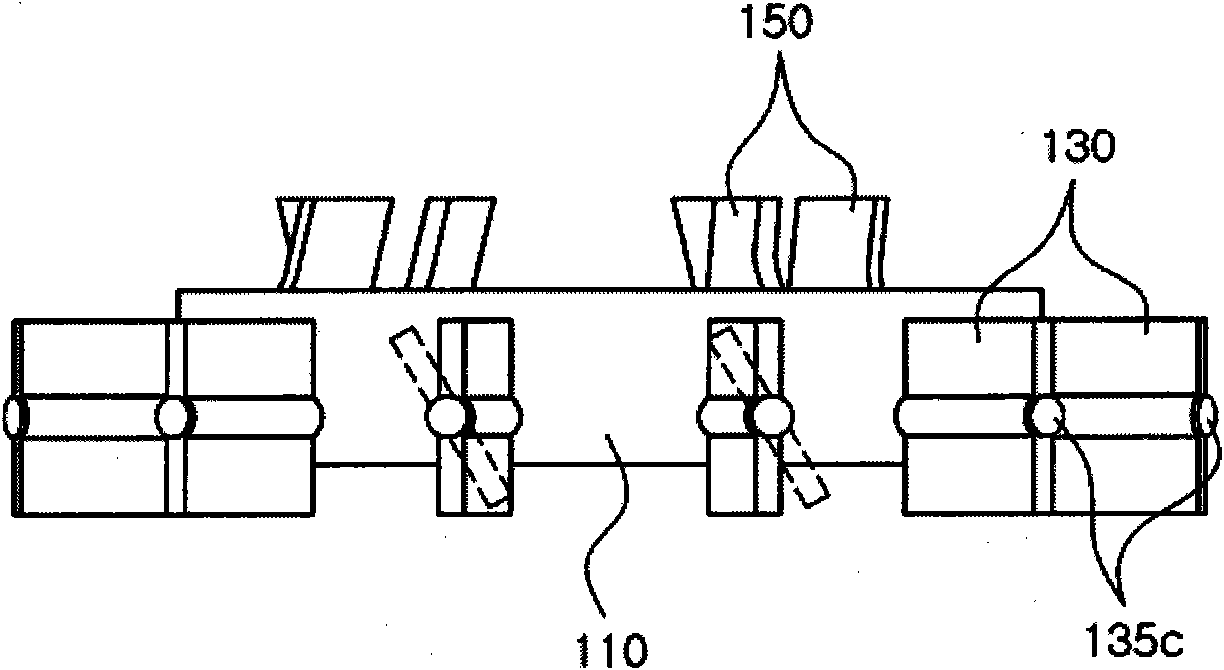

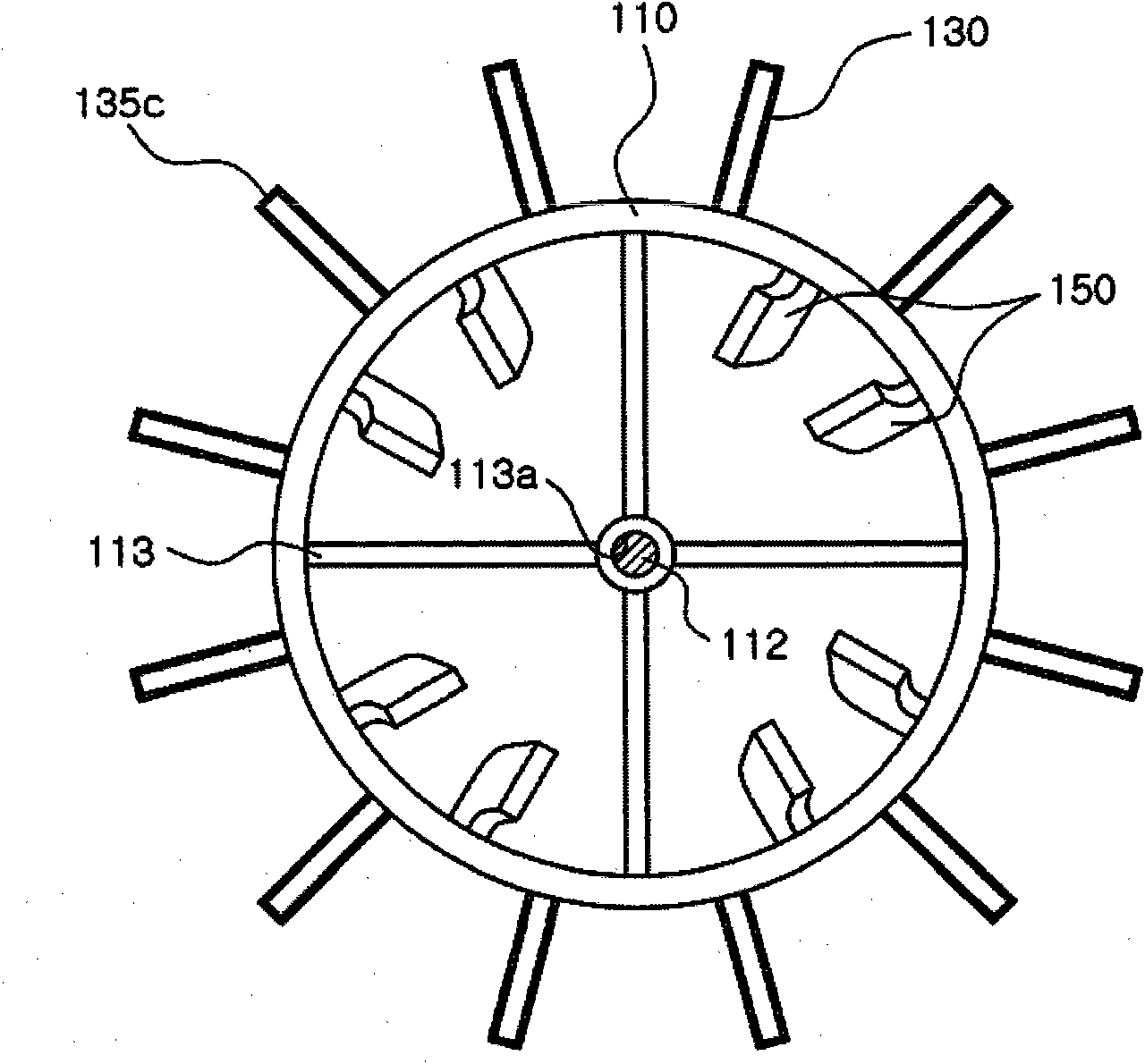

[0041] figure 1 is a configuration diagram showing a local exhaust system capable of controlling turbulence according to a first exemplary embodiment of the present invention, and FIG. 2( a ) is along figure 1 The front view taken in the direction of the arrow A in Fig. 2(b) is along the figure 1 Front view taken in the direction of arrow B in, image 3 is an exploded perspective view showing a local exhaust system capable of controlling turbulence according to a first exemplary embodiment of the present invention.

[0042] like Figures 1 to 3 As shown in , the local exhaust system 100 according to the first exemplary embodiment of the present invention includes an exhaust pipe 101 , a motor 109 , a rotor structure 110 and turbulence-generating outer blades 130 .

[0043] The exhaust pipe 101 may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com