Vacuum valve

A vacuum valve and valve core technology, which is applied to lift valves, valve details, safety valves, etc., can solve the problems of changing the bending amount of the annular sealing member 122 and restricting the position movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Hereinafter, one embodiment of the vacuum valve according to the present invention will be described with reference to the drawings.

[0064]

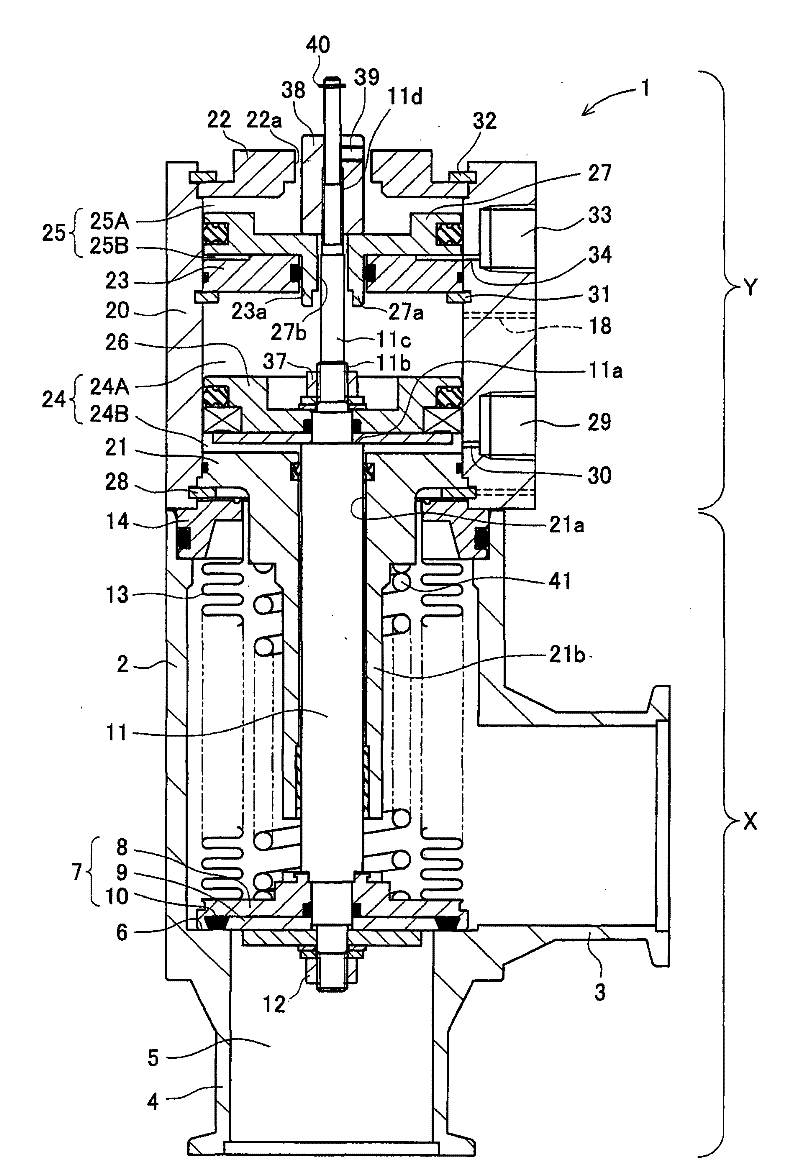

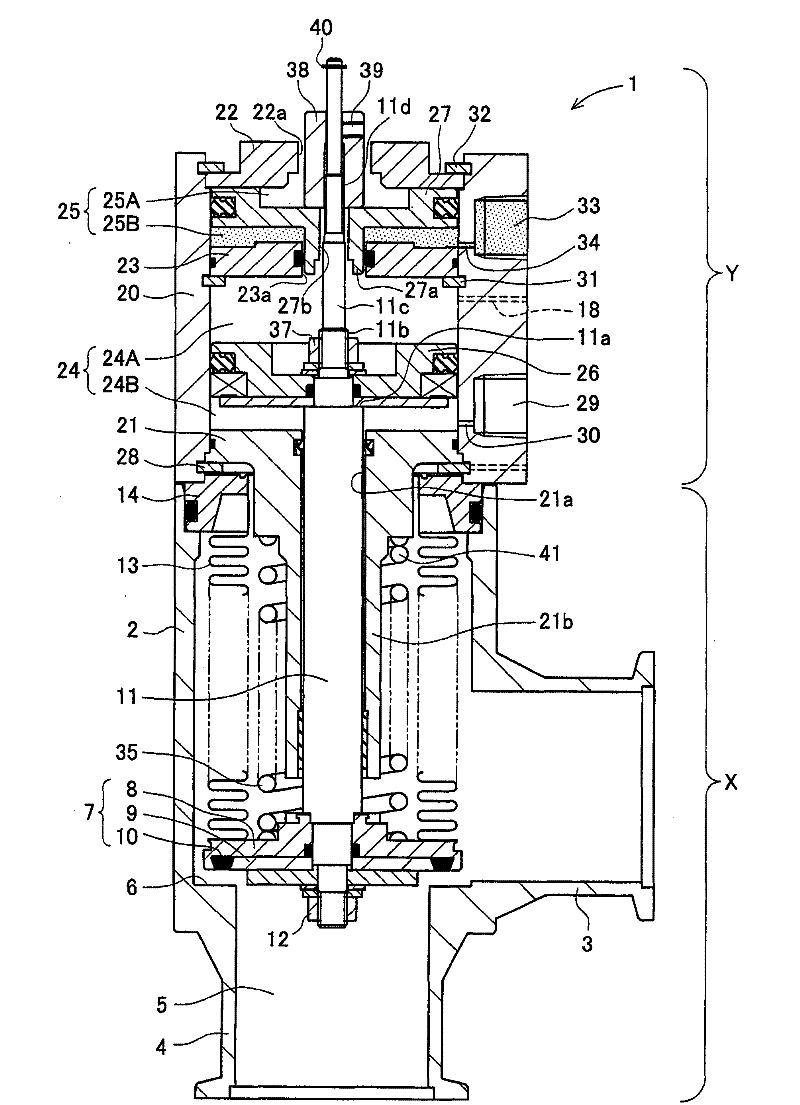

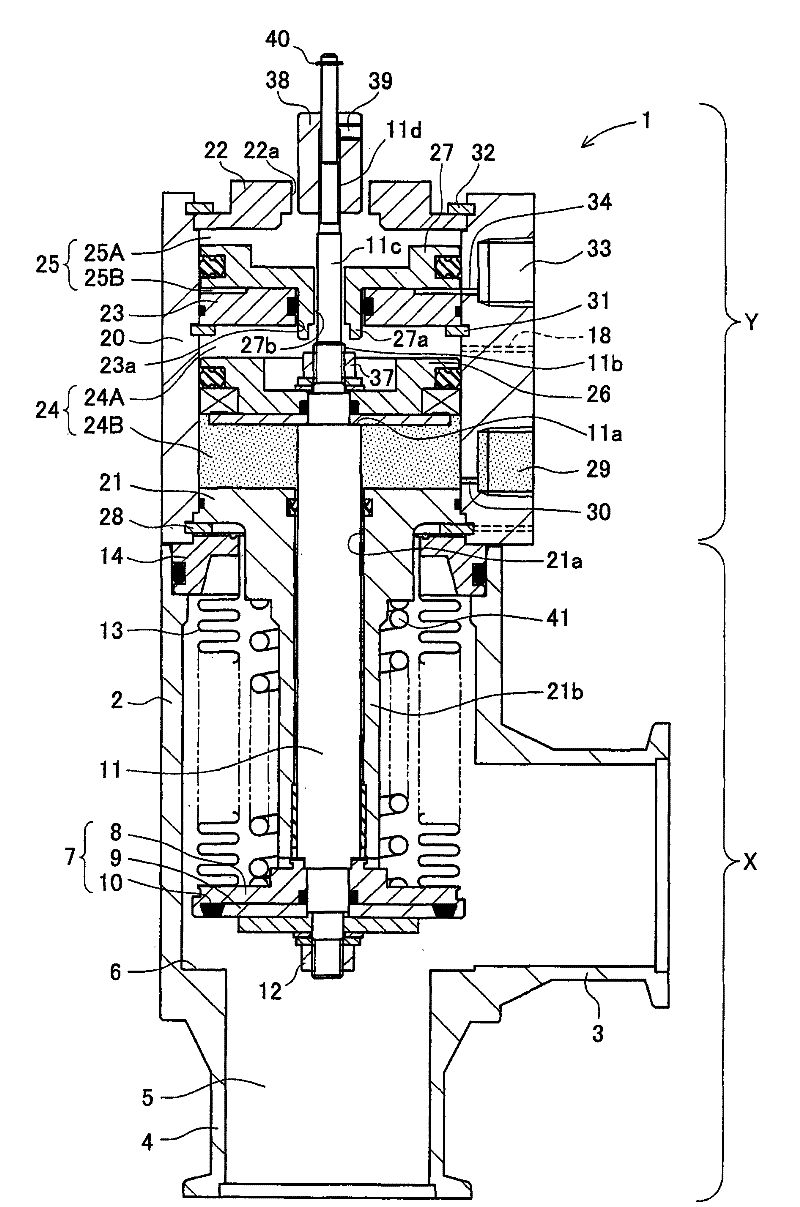

[0065] Figure 1 to Figure 3 It is a sectional view showing an embodiment of the vacuum valve 1, figure 1 is a diagram showing the closed valve state, figure 2 is a graph representing a slow exhaust state, and image 3 is a diagram showing a rapid exhaust state. for Figure 1 to Figure 3 In all cases, the stroke adjustment member 38 is arranged at the lowest position. and, Figure 4 for figure 1 The top view of the vacuum valve 1 shown.

[0066] Figure 1 to Figure 4 The shown vacuum valve 1 is disposed between a chamber of a semiconductor manufacturing apparatus and a vacuum pump, as in the prior art.

[0067] Such as Figure 1 to Figure 3 As shown, the vacuum valve 1 is composed of a lower valve part X and an upper driving part Y. The vacuum valve 1 changes the stroke of the spool 7 by moving the first piston 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com