Variable-ventilatory-capacity sine gas supply device and high-simulation-degree HME moisture loss tester

A gas supply device and ventilation volume technology, which is applied in the direction of pharmaceutical equipment, other medical equipment, respirators, etc., can solve the problems of poor accuracy, poor reliability, and poor clinical reference of HME water loss testers, and improve clinical reference The effect of reliability, reliable flow direction, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

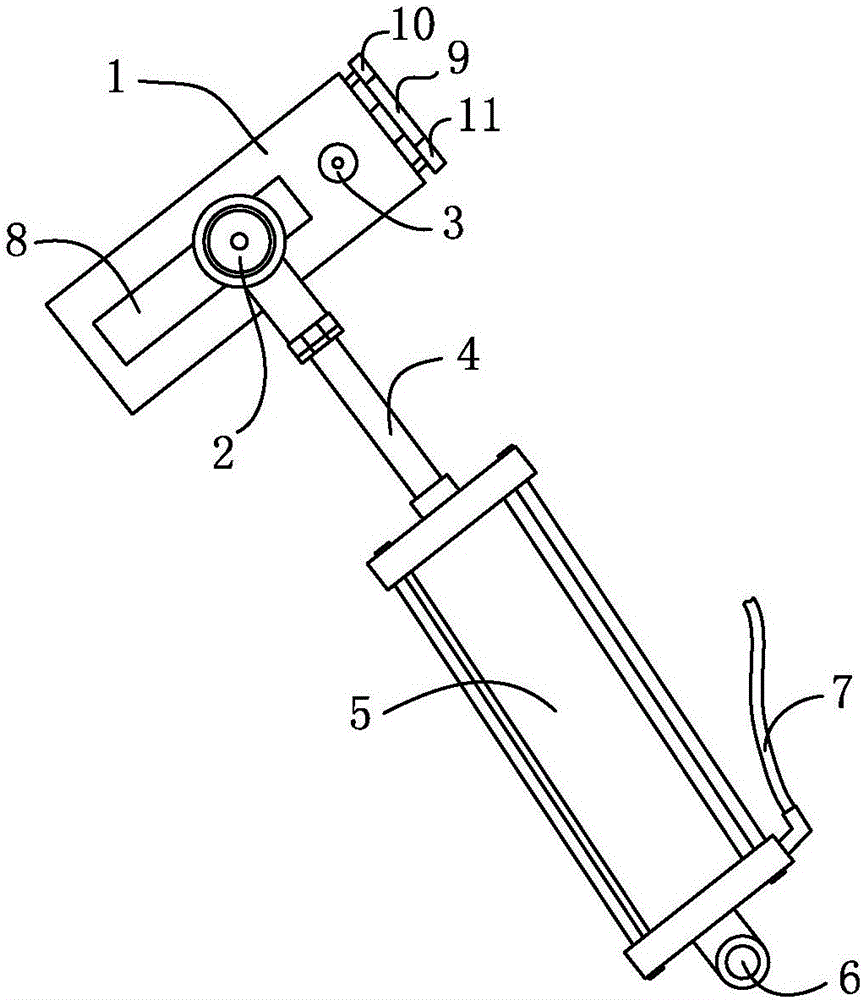

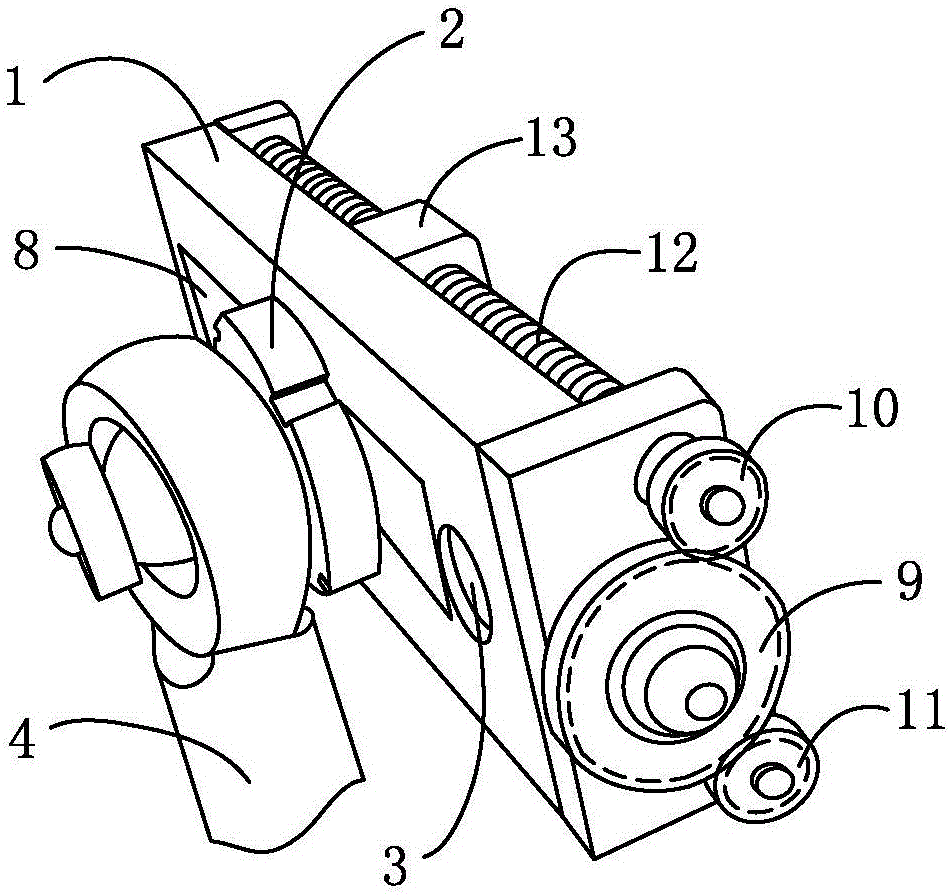

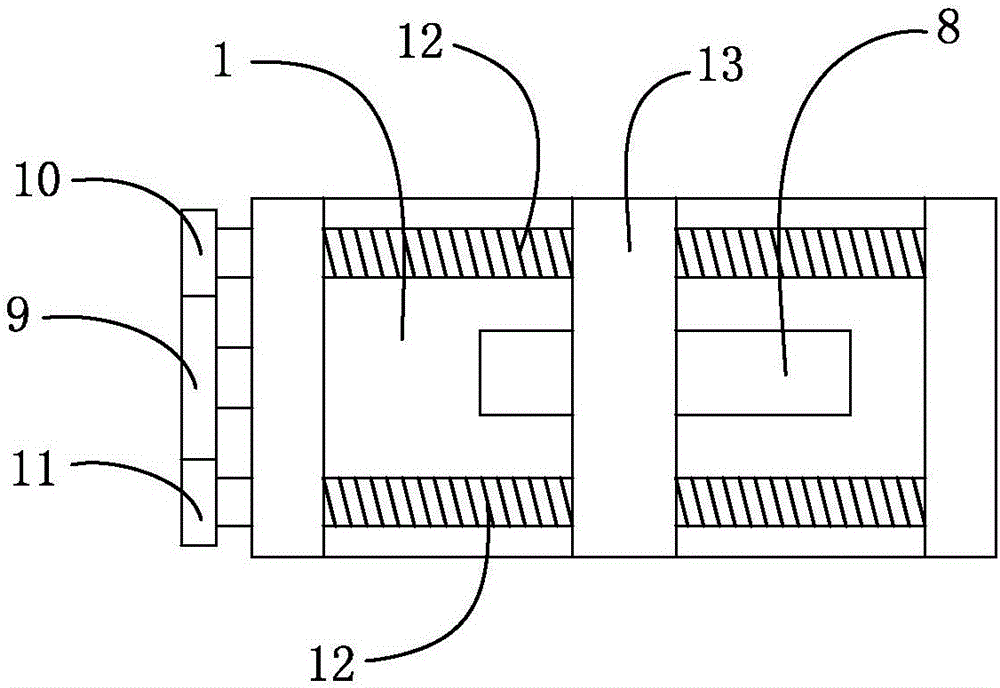

[0056] Such as figure 1 As shown, the sinusoidal air supply device with variable air flow includes a crank 1, a slider 2 and a cylinder 5. The crank 1 is fixedly connected with the drive shaft 3, and the crank 1 is provided with a long strip on one side of the drive shaft 3. Slideway 8, described slide block 2 is installed in slideway 8, and slide block 2 can move along slideway 8 and can be positioned in slideway 8; One end of described cylinder 5 stretches out piston rod 4, and the other end of cylinder 5 One end is provided with an air delivery pipe 7 communicating with the inside of the cylinder 5; the end of the piston rod 4 is connected to the slider 2 in a rotatable manner.

[0057] The motor connected to the drive shaft 3 is connected to the frequency converter, and both the motor and the frequency converter are powered by a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com