Method for quickly and precisely casting complex parts

A technology of precision casting and complex parts, which is applied in the field of rapid precision casting of complex parts, can solve the problems of low shell forming efficiency, difficult casting mold manufacturing, long shell making cycle, etc., to achieve shortened production cycle, high forming efficiency, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

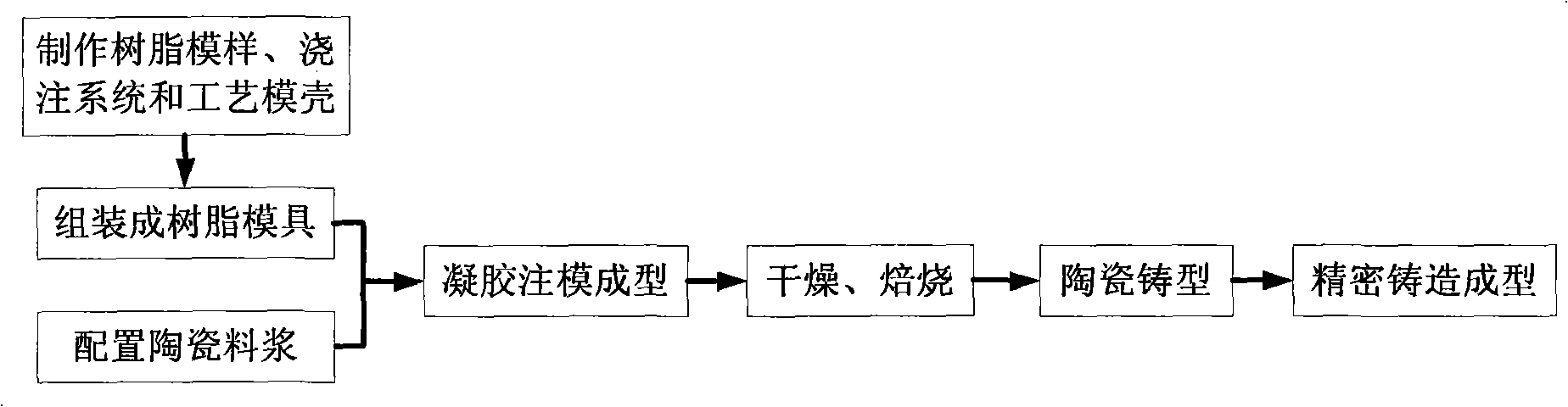

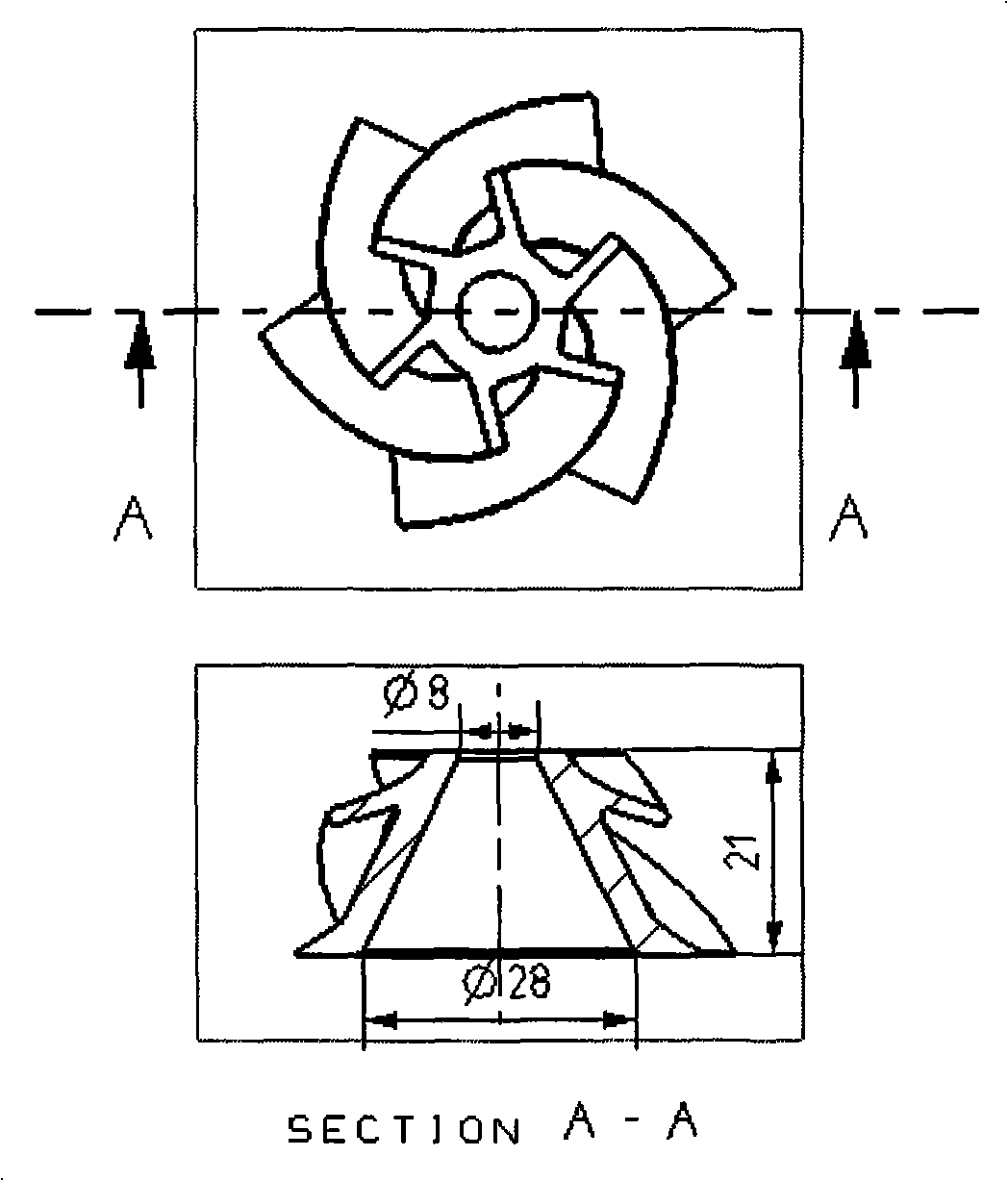

[0031] Example 1, see figure 1 ,2,3, figure 2 The impeller shown has a complex curved surface shape, and the distance between the blades is very narrow, and its profile is difficult to design, so it is difficult to manufacture, and the process proposed in the present invention can solve this problem well. The specific implementation steps are as follows:

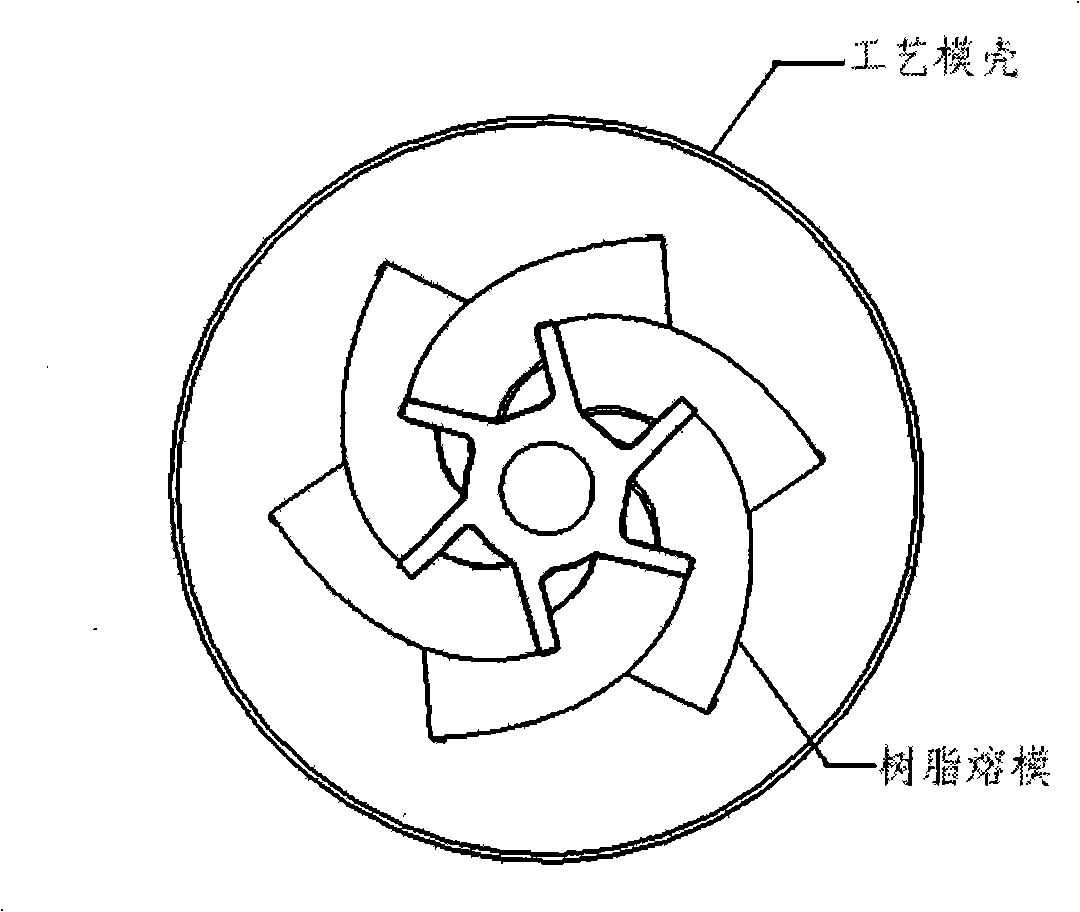

[0032] 1) Preparation of resin investment mold: use 3D modeling software to figure 2 The three-dimensional model of the impeller shown is subjected to shelling processing, and the solid parts are pumped into hollow parts, and the wall thickness of the shell is 0.6mm, and then the resin model of the part is made by using the light-curing rapid prototyping equipment; the surface of the resin model is prefabricated for discharge Pores for excess resin;

[0033] Using light-curing rapid prototyping equipment, the prototype of the resin casting system was produced;

[0034] Use light-curing rapid prototyping equipment to ma...

Embodiment 2

[0050] Embodiment 2,1) rapid preparation of resin mold

[0051] Use 3D modeling software to extract the shell of the 3D model of the part to be prepared, extract the solid part into a hollow part, and the wall thickness of the shell is 1mm, and then use the light-curing rapid prototyping equipment to make the resin shape of the part;

[0052] Using light-curing rapid prototyping equipment, the prototype of the resin casting system was produced;

[0053] Use light-curing rapid prototyping equipment to make a resin mold shell with an outer profile larger than the resin pattern with one end opening, assemble the resin pattern, pouring system and resin mold shell together to form a resin mold, and the distance between the resin pattern and the resin mold shell is 10mm, used to fill ceramic slurry to form a mold;

[0054] 2) Configure high solid phase, low viscosity ceramic slurry

[0055] a. Ingredients: take deionized water or distilled water, and take ceramic powder silicon ox...

Embodiment 3

[0069] Embodiment 3,1) rapid preparation of resin mold

[0070] Use 3D modeling software to extract the shell of the 3D model of the part to be prepared, extract the solid part into a hollow part, and the wall thickness of the shell is 1.5mm, and then use the light-curing rapid prototyping equipment to make the resin shape of the part;

[0071] Using light-curing rapid prototyping equipment, the prototype of the resin casting system was produced;

[0072] Use light-curing rapid prototyping equipment to make a resin mold shell with an outer profile larger than the resin pattern with one end opening, assemble the resin pattern, pouring system and resin mold shell together to form a resin mold, and the distance between the resin pattern and the resin mold shell is 10mm, used to fill ceramic slurry to form a mold;

[0073] 2) Configure high solid phase, low viscosity ceramic slurry

[0074] a. Ingredients: take deionized water or distilled water, and take ceramic powder zirconia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com