Method of producing seam-welded pipe having good welded portion characteristics

A resistance welding, characteristic technology, applied in manufacturing tools, high-frequency current welding equipment, welding equipment, etc., can solve problems such as production efficiency decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] The following description will be made based on the examples.

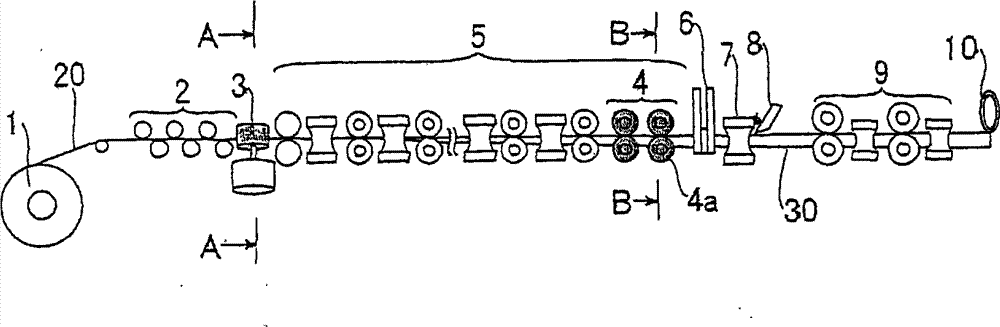

[0140] figure 1 The tube manufacturing machine used in the examples is shown. The pipe manufacturing method using this pipe manufacturing machine is as follows. The strip 20 is unrolled from the uncoiler 1; the strip is then re-flattened by a flattener 2; the strip 20 is then gradually rounded by a roll former 5; then the strip 20 is then rounded by means of a resistance welding machine (including an induction heating section 6 and squeeze roll (resistance welded part) 7) carry out electric resistance welding to the two transverse edges of the band that transversely becomes round, thereby form pipe 30; Then cut off the weld seam part of pipe 30 by weld seam cutter 8; The diameter machine 9 adjusts the outer diameter of the pipe 30 after cutting; and then the pipe is cut to a predetermined length by the pipe cutter 10 . The roll former 5 has a first roughing stand 13 at the previous stage, and a fin rolli...

Embodiment 2

[0146] In Inventive Example 2, except that the taper angle α in Inventive Example 1 was changed to 40°, the tube was manufactured in the same manner as in Inventive Example 1, and the tube was subjected to a Charpy test to evaluate its performance.

Embodiment 21

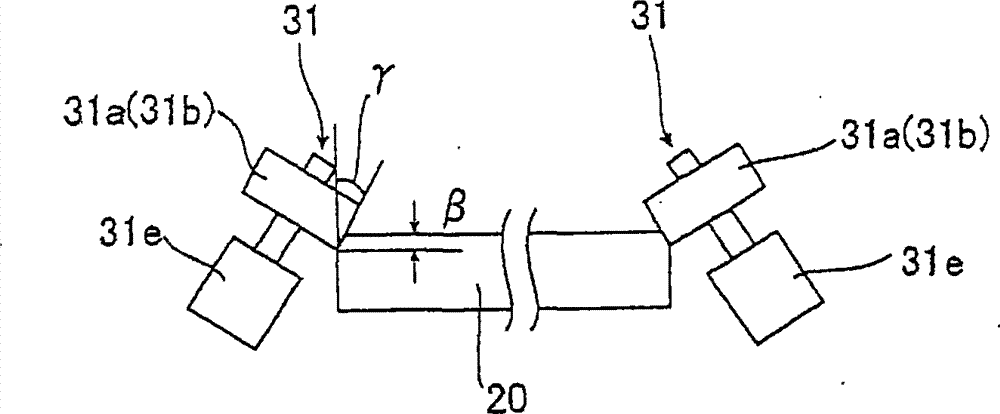

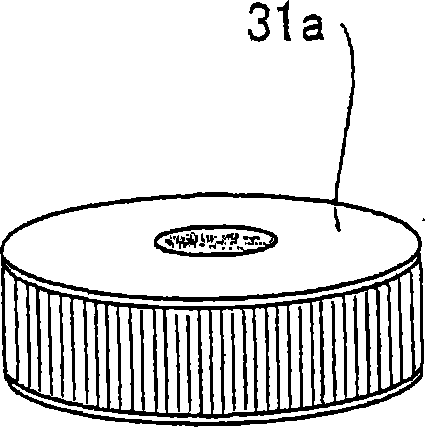

[0162] In Example 21 of the present invention, the above-mentioned electric resistance welded pipe was manufactured according to the first embodiment. In manufacturing, using Figure 3A Cutting rollers 31a are shown as cutting or planing means 31 for forming tapers on both transverse edges at the upper surface side of the strip. The inclination angle α of the tapered shape was made to be 30° both at the upper surface side and the lower surface side. When the thickness of the strip is changed from 19.1mm to 11.3mm, the vertical position of the cutting roller 31a is moved down by 7.8mm for fine adjustment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com