Tool bit rock breaking mechanism and abrasion tester

A wear-resistant testing machine and cutting tool technology, which is applied in the direction of testing wear resistance and testing machinability, and can solve problems such as inability to carry out experimental research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

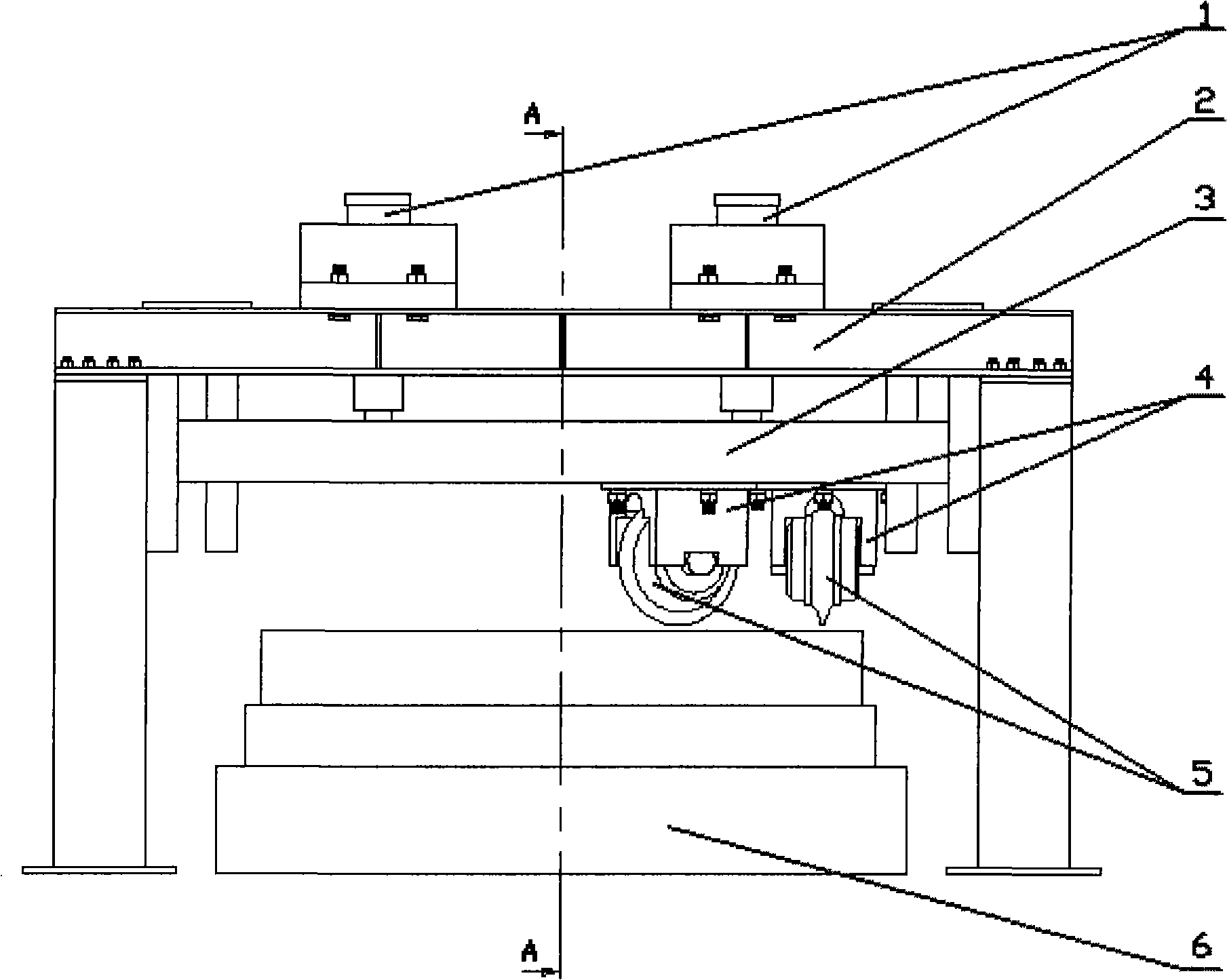

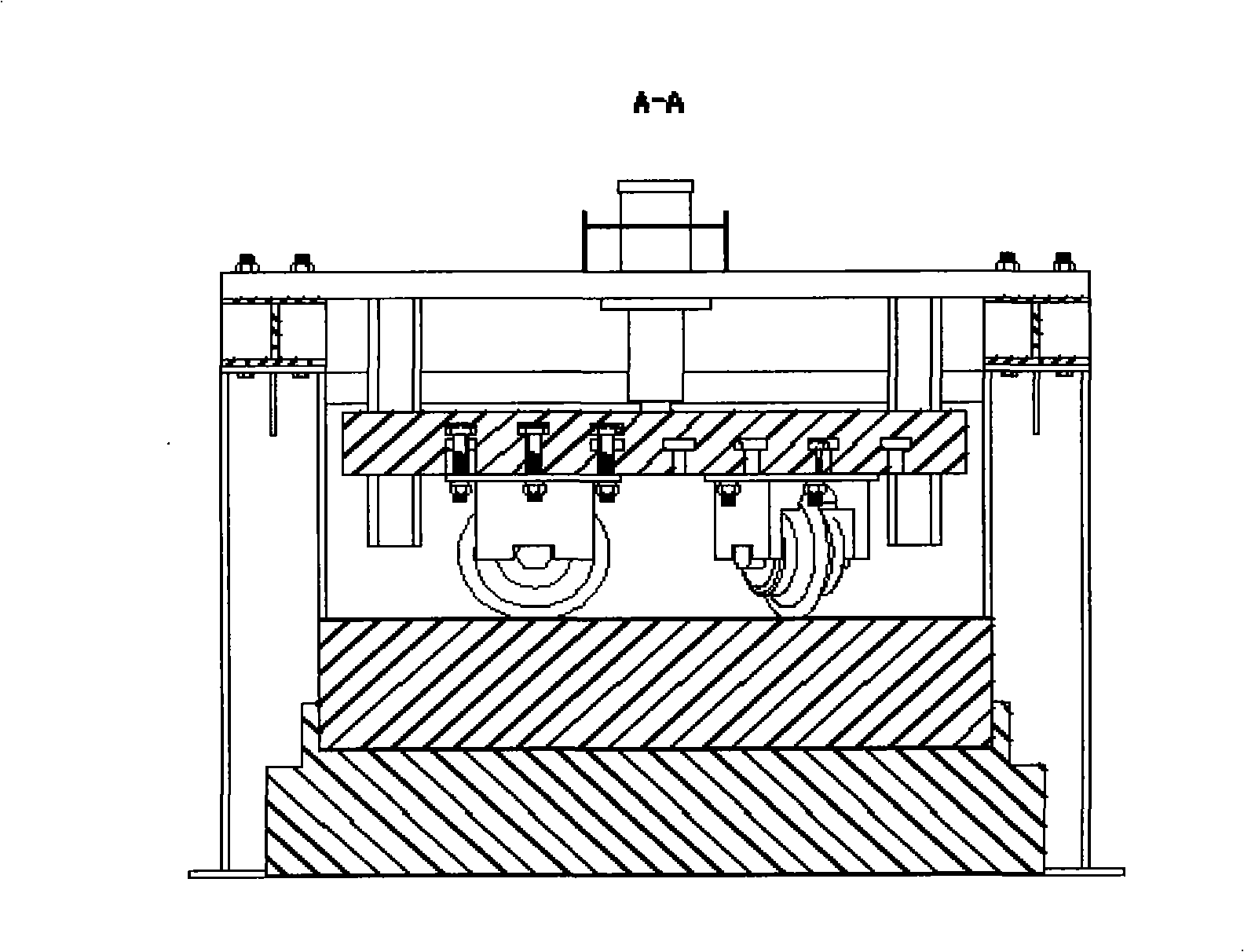

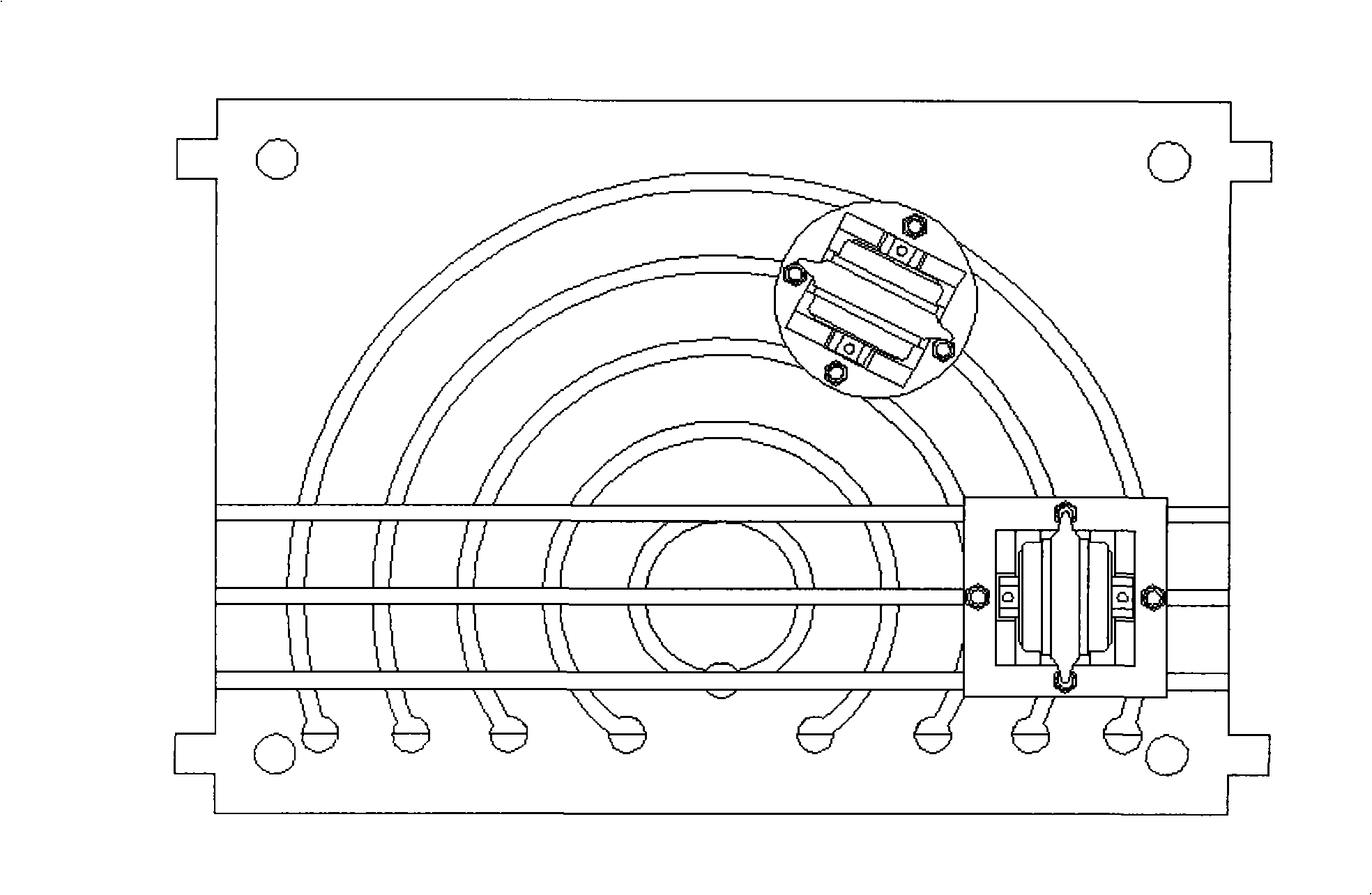

[0011] Referring to the accompanying drawings, the rock-breaking mechanism and wear-resisting test machine of the tool includes a hydraulic cylinder 1, a structural frame 2, a pressure-bearing plate 3, a tool holder 4, a disc-shaped hob 5, and a rotary table 6. The rock-breaking mechanism and wear-resistant of the tool When the testing machine is working, the disc-shaped hob 5 is connected to the tool holder 4 through bolts, and the tool holder 4 is fixed on the pressure-bearing plate 3 through bolts, and the hydraulic cylinder 1 applies a certain load to make the disc-shaped hob 5 be pressed and placed. On the rock sample on the workbench 6, a certain degree of penetration is generated, and then the workbench 6 is rotated through the power system, and the rock is passively cut; In the wear resistance test of the tool, two knives were cut at the same time to do the knife spacing and phase angle experiment. There are grooves on the pressure bearing plate 3, and the adjustment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com