Mechanical synchronizer for main driving motor of disc shear

A main drive motor, mechanical synchronization technology, applied in the control of the speed or torque of the motor, electrical components, control systems, etc., can solve the difficulties in the production and processing of synchronous connecting shafts, the dynamic balance of the connecting shafts cannot be guaranteed, and it is prone to danger and other problems, to achieve the effects of high motor synchronous control accuracy, stable and safe synchronous operation, and convenient adjustment and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

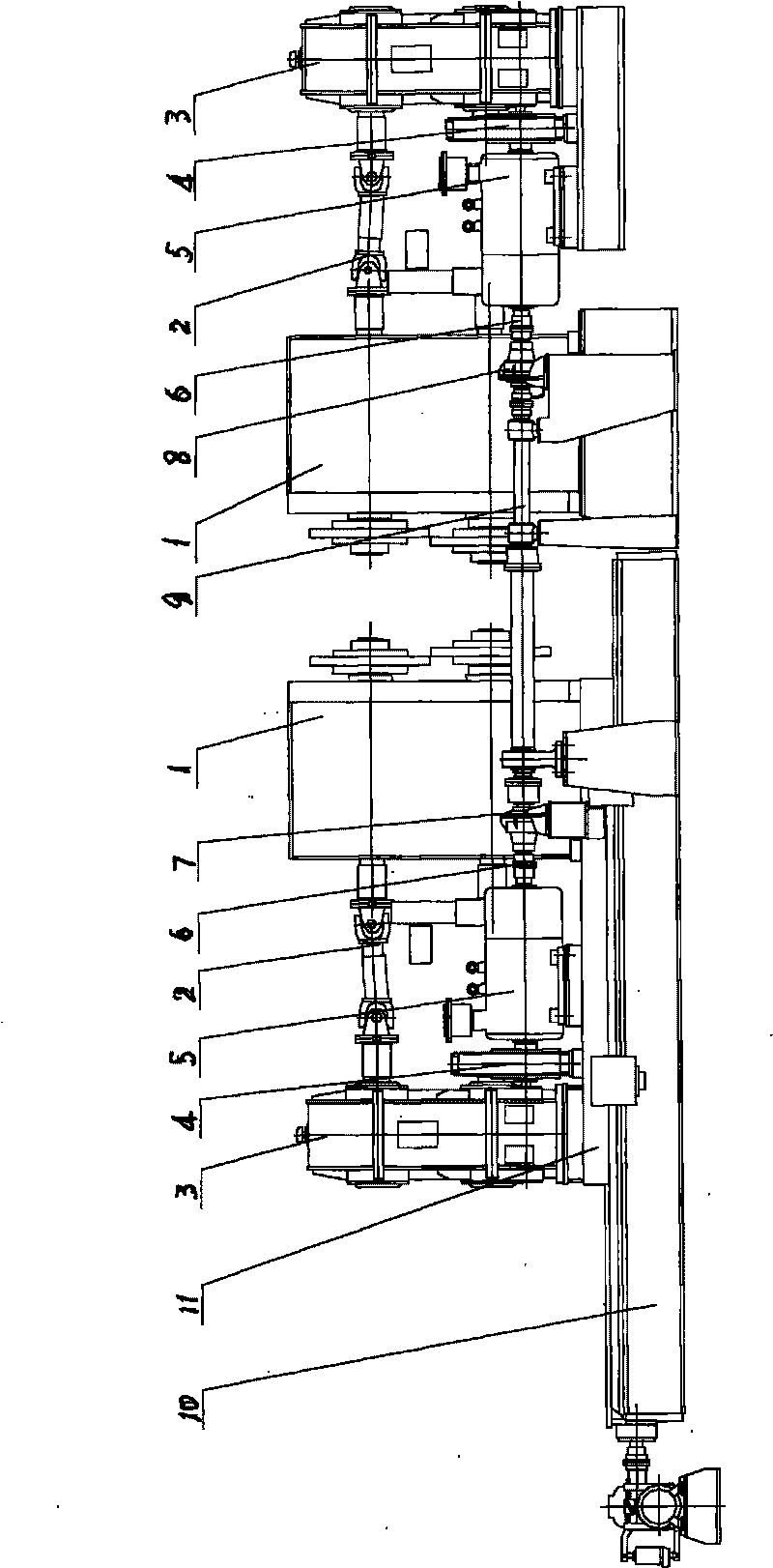

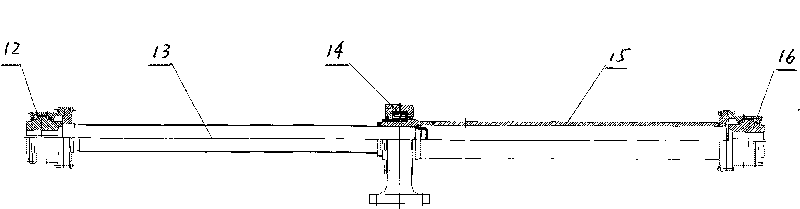

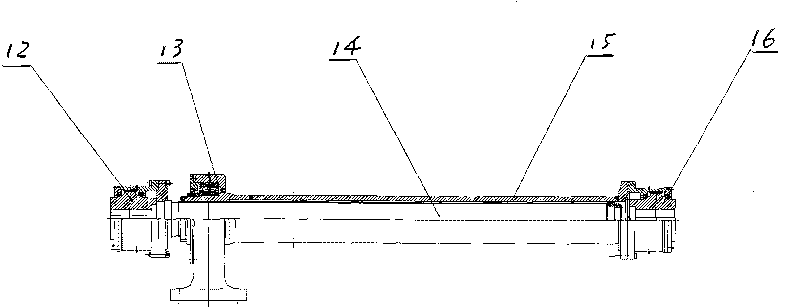

[0011] Referring to the accompanying drawings, a mechanical synchronization device for the main drive motor of disc shears, the whole device consists of a shear body 1, a universal coupling 2, a main drive reducer 3, a brake coupling 4, a main drive motor 5, The first drum gear coupling 6, the moving side cycloid reducer 7, the fixed side cycloid reducer 8, the fixed side rigid synchronous shaft 9, the traversing base 10, the sliding seat 11, the second drum The tooth coupling 12, the spline shaft 13, the middle support seat 14, the spline sleeve 15, and the third drum-shaped tooth coupling 16 are composed. Make the upper and lower cutter heads of the disc shears rotate in a certain direction, so as to continuously cut the two sides of the moving steel plate to meet the accuracy requirements of the fixed width of the steel plate; the main drive reducer 3 passes through four universal couplings 2 It is connected with the shearing machine body 1 on both sides, the main transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com