Method and apparatus for preparing high-pure carbon tetrafluoride gas

A high-purity carbon tetrafluoride and carbon tetrafluoride technology, which is applied in the direction of fluoride preparation, can solve the problems of severe equipment corrosion, expensive raw materials, low product purity and yield, and achieve equipment operation safety and gas purity. High, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

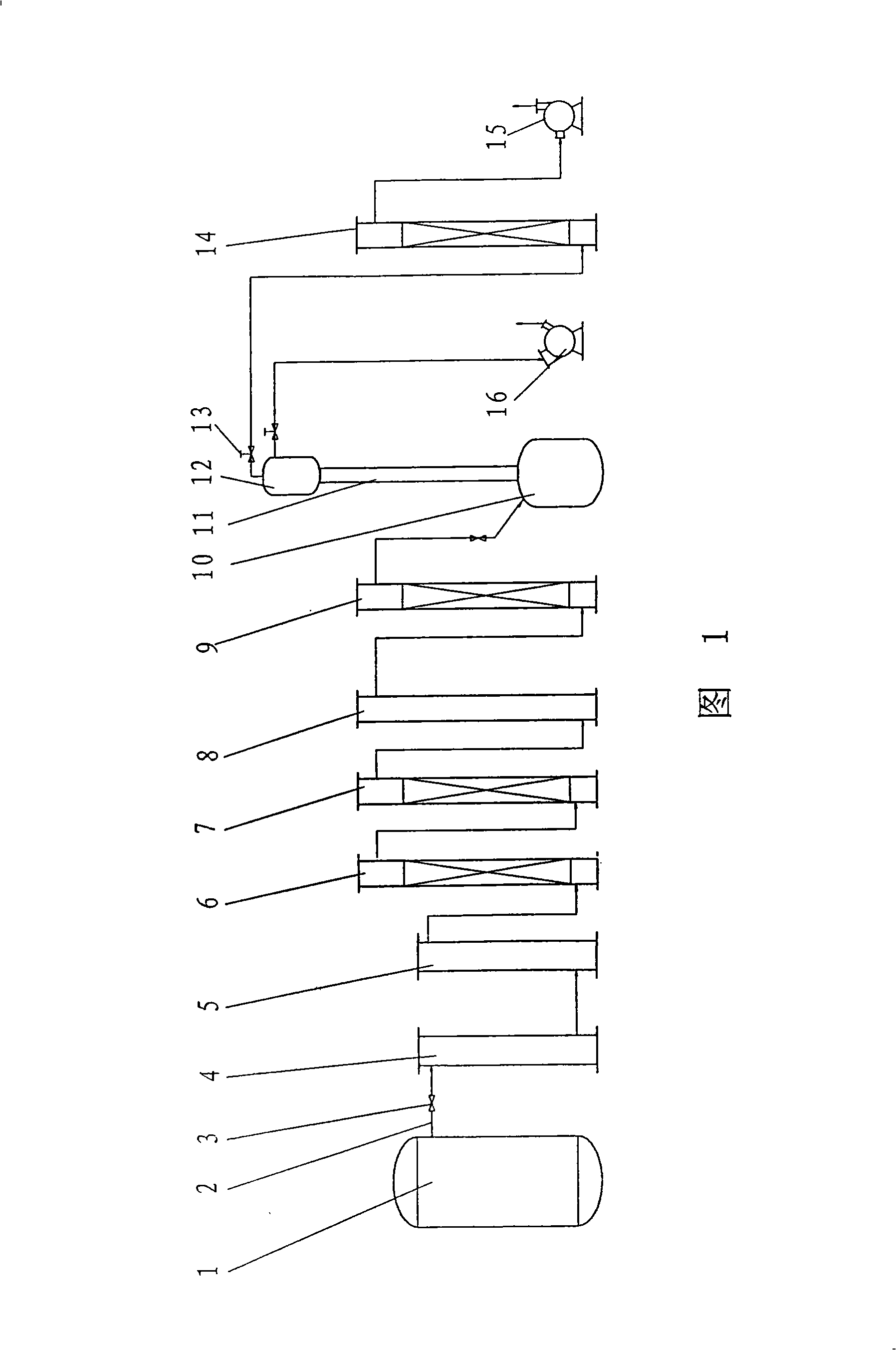

[0070] After adding 60 kg of high-purity activated carbon (carbon content of 93%) into the reactor 4, the reactor 4 is preheated to 155°C, and the pressure of the fluorine gas storage tank 1 is -0.01Mpa. Open the reactor 4 inlet valve 3, the fluorine gas enters the reactor 4 through the pipeline 2 and directly undergoes the synthesis reaction with high-purity activated carbon, and the reaction product is carbon tetrafluoride gas containing impurities.

[0071] Analyze the composition of the outlet gas of the reactor 4, the main component is carbon tetrafluoride (CF 4 ) Gas with a small amount of hydrogen (H 2 ), oxygen (O 2 ), nitrogen (N 2 ), fluorine gas (F 2 ), silicon tetrafluoride (SiF 4 ), hexafluoroethane (C 2 F 6 ), octafluoropropane (C 3 F 8 ), carbon dioxide (CO 2 ).

[0072] The carbon tetrafluoride gas containing impurities is passed through the dust collector 5 to remove solid matter. The operating pressure of the dust collector 5 is -0.020Mpa; the carbon tetrafluorid...

Embodiment 2

[0078] After adding 64 kg of high-purity activated carbon (95% carbon content) into the reactor 4, the reactor 4 is preheated to 162°C, and the pressure of the fluorine gas storage tank 1 is -0.008Mpa. Open the reactor 4 inlet valve 3, the fluorine gas enters the reactor 4 through the pipeline 2 and directly undergoes the synthesis reaction with high-purity activated carbon, and the reaction product is carbon tetrafluoride gas containing impurities.

[0079] Analyze the composition of the outlet gas of the reactor 4, the main component is carbon tetrafluoride (CF 4 ) Gas, and the gas contains a small amount of hydrogen (H 2 ), oxygen (O 2 ), nitrogen (N 2 ), fluorine gas (F 2 ), silicon tetrafluoride (SiF 4 ), hexafluoroethane (C 2 F 6 ), octafluoropropane (C 3 F 8 ), carbon dioxide (CO 2 ).

[0080] The carbon tetrafluoride gas containing impurities is removed by the dust collector 5, and the operating pressure of the dust collector 5 is -0.018Mpa; the carbon tetrafluoride gas fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com