Automatic feeding mechanism

An automatic feeding and feeding technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of too many manpower and only one machine can be managed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

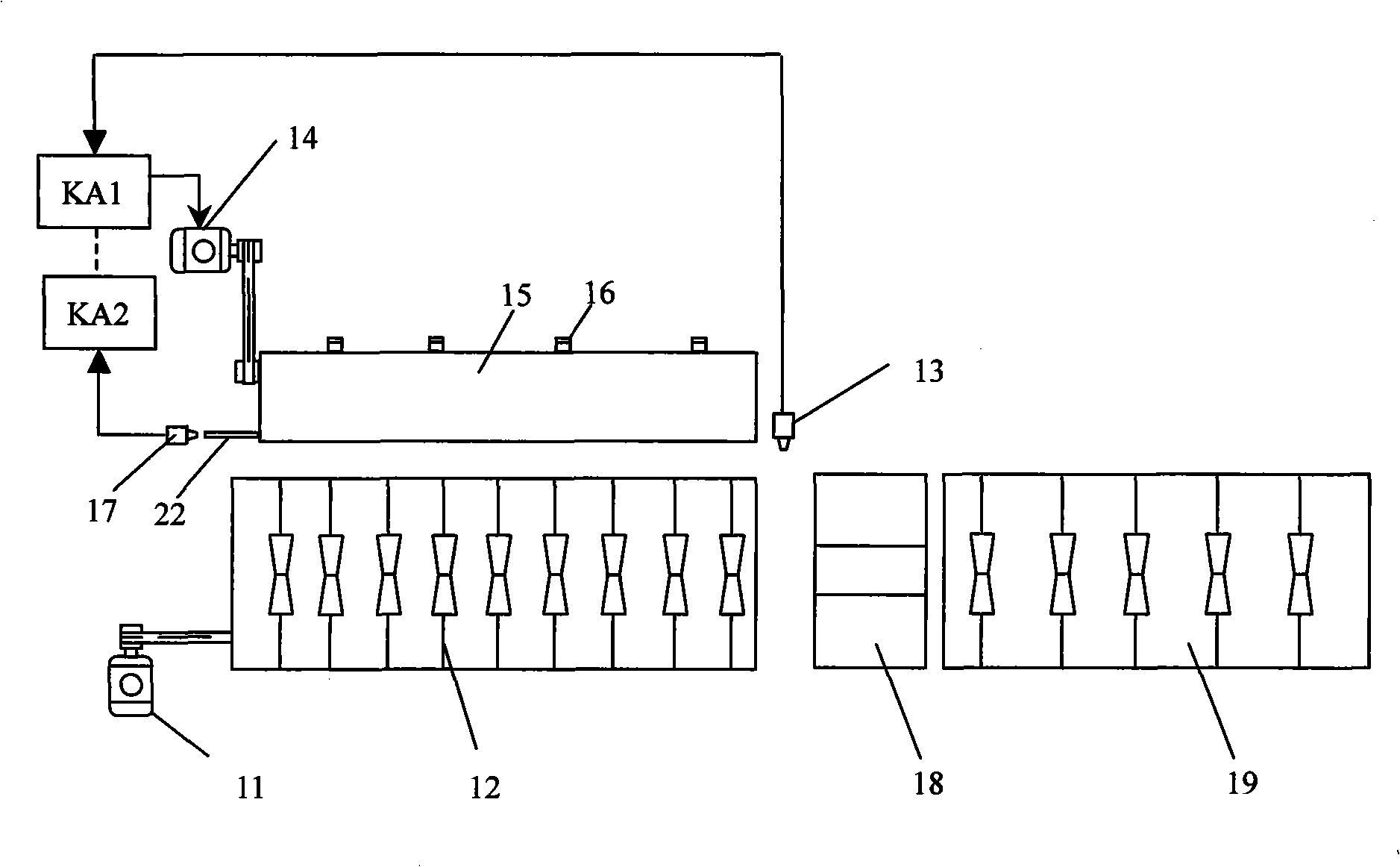

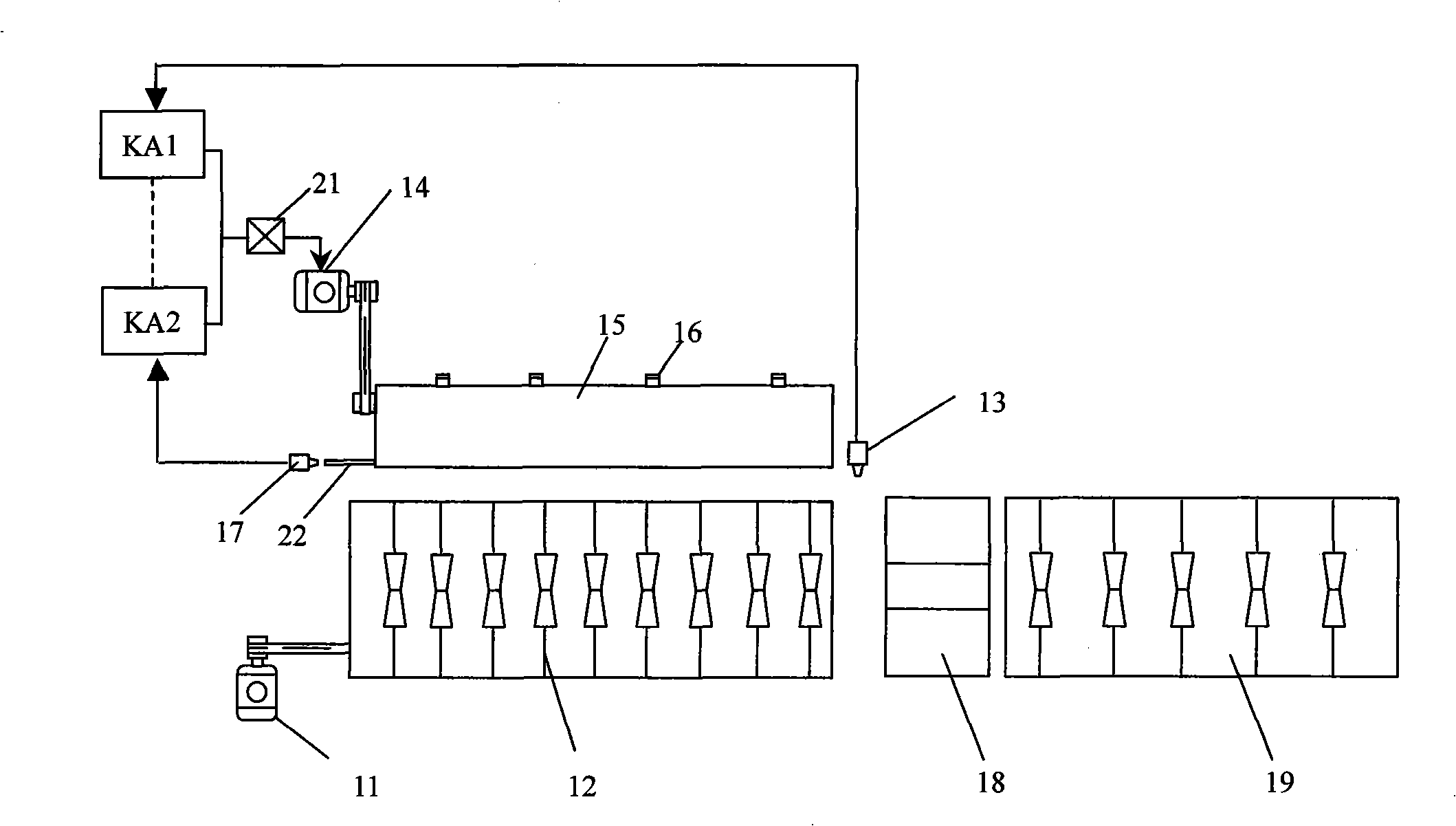

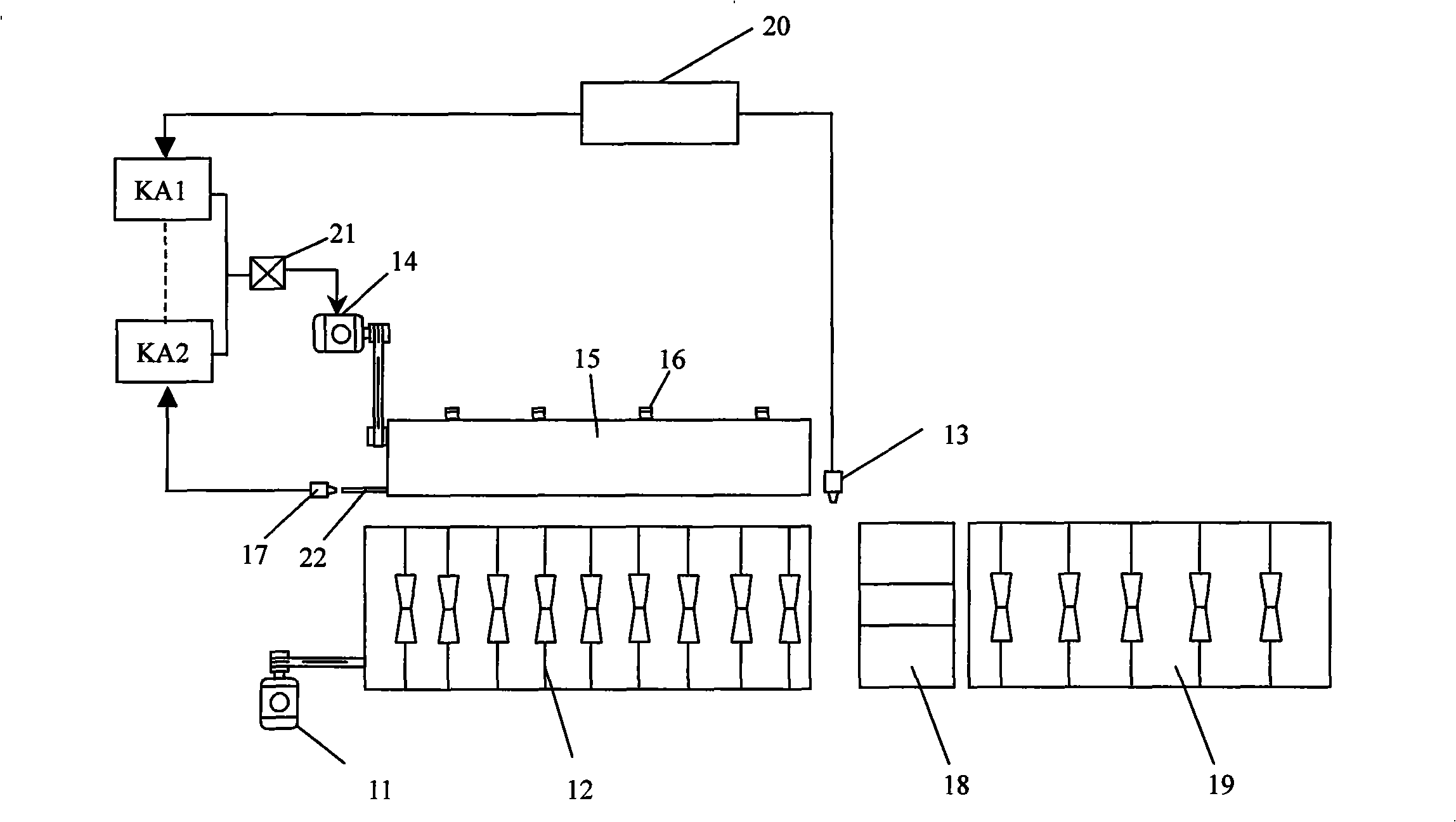

[0011] from figure 1 It can be seen that when the roller group 12 is driven by the driving device 11 composed of a motor and a deceleration mechanism, the feeding roller group 12 rotates in the same direction, so that the workpiece can be fed in the direction that it should move. The feed detection sensor 13 fixedly arranged at the end of the feed roller group 12 adopts a photoelectric switch, such as a normally closed photoelectric switch E3F-DS10Y2. The sensor 13 is facing the workpiece forwarded to the processing area or the processing area 18 by the feed roller set, and when the workpiece is being forwarded into the processing area or the processing area 18, the sensor 13 can sense the presence of the workpiece. At this time, the transistor in the photoelectric switch of the sensor 13 is turned off, and no signal is sent. When the workpiece completely passes through the roller set 12 and then completely enters the machining area 18 through the detection area of the sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com