Gas-liquid contact type non-phase-change middle medium heat exchange wet-type desulfuration method and apparatus

A gas-liquid contact and desulfurization device technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high operating costs, prone to condensation, and equipment corrosion, so as to ensure safe operation and avoid problems. The effect of blocking ash and preventing acid dew corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

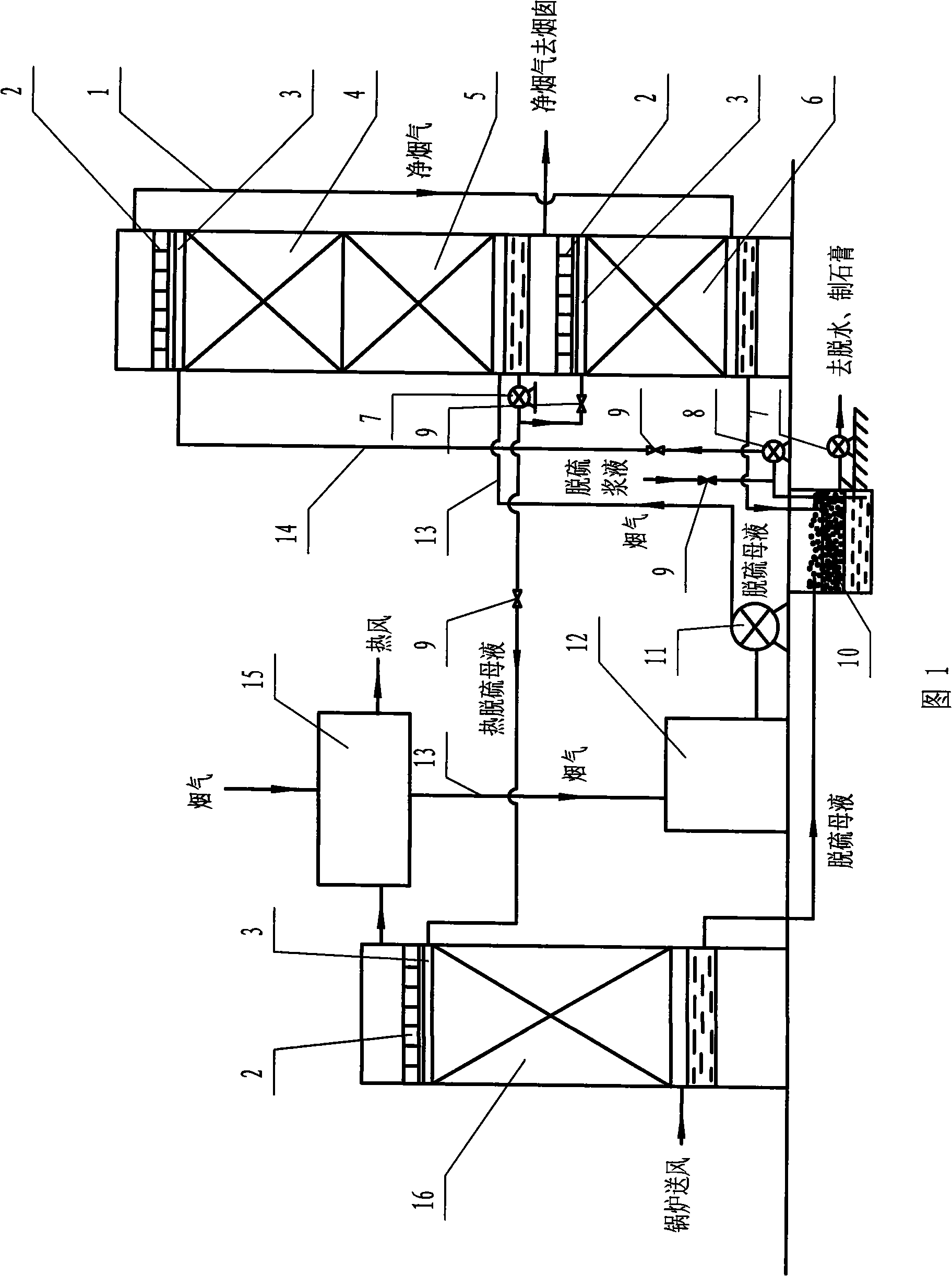

[0024] It can be seen from Figure 1 that this gas-liquid contact non-phase-change intermediate medium heat exchange wet desulfurization device includes flue gas cooling section 5, desulfurization section 4, clean flue gas heating section 6, air preheating section 16 and desulfurization mother liquor Settling tank 10 has five parts, the desulfurization section 4 is directly connected to the flue gas cooling section 5, and the flue gas cooling section 5 is respectively connected to the net flue gas heating section 6 and the air preheating section 16 through the mud pump 7 so as to send the desulfurization mother liquor into the net In the respective spray devices 3 of the flue gas heating section 6 and the air preheating section 16, the air preheating section 16 is also connected to the air preheater 15 to heat the inlet temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com