Carbon fiber autoclaved aerated concrete slab and application thereof

A technology of autoclaved air filling and concrete slabs, which is applied in the direction of floors, building components, building materials, etc., can solve the problems that the degree of internal damage cannot be monitored, etc., to eliminate degradation and deterioration, reduce overall weight, and improve thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

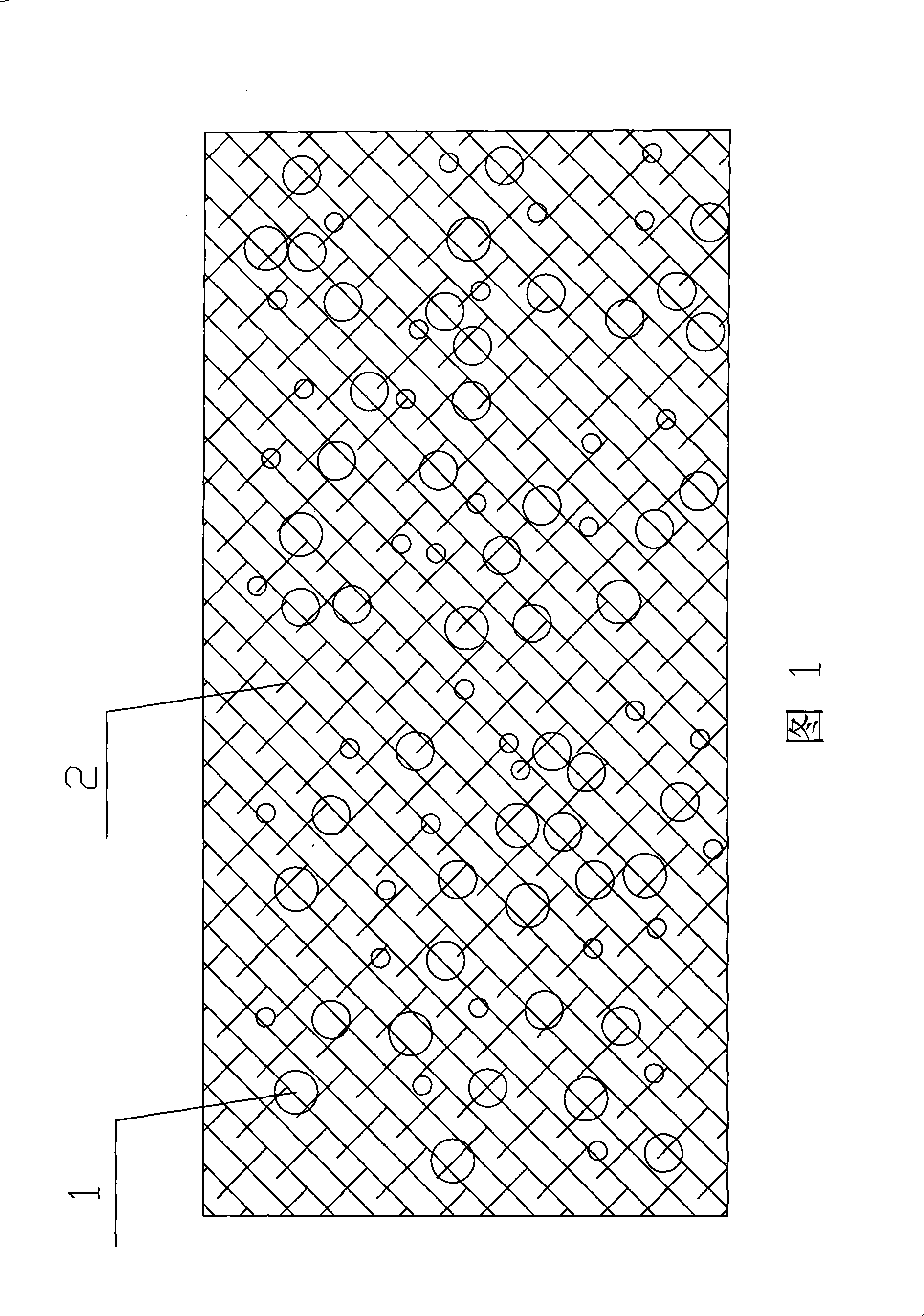

[0024] The carbon fiber autoclaved aerated concrete slab comprises: a concrete structural slab for construction, the concrete is autoclaved aerated concrete 1, and carbon fibers 2 are distributed in the concrete of the structural slab.

[0025] The carbon fiber is a PAN-based carbon fiber reinforced cement-based composite material with a fiber length of 3-10 mm, and the carbon fiber compound is added in an amount of 0.74-3% of the total weight, such as 1%, 1.5%, 2%, 2.5% surface activity The addition amount of agent is 0.5-1% of total weight.

Embodiment 2

[0027] In the carbon fiber autoclaved aerated concrete slab described in Example 1, the surfactant is live silica fume and / or ground blast furnace slag and / or methylcellulose and / or carboxymethylcellulose, and each component is The proportioning of the prior art can be adopted, the cement used in the concrete is finely ground Portland cement with a maximum particle diameter of less than 45 microns, and the fine aggregate in the cement formula is silica sand or pulverized coal For the ash or volcanic microbeads or their composites, the ratio of the components in the prior art can be adopted, and the maximum diameter thereof is not greater than 0.2 mm.

Embodiment 3

[0029] An application of the above-mentioned autoclaved aerated concrete slab containing carbon fiber as a floor slab, a roof slab, and a wall slab.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com