Method for preparing fatty acid by using lipase hydrolyzation of oil and fat

A technology for hydrolyzing oil and lipase, applied in the biological field, can solve the problems of increasing the hydrolysis rate of emulsifiers and speeding up the reaction process, and achieving the effects of less enzyme consumption, lower production costs, and increased collision opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

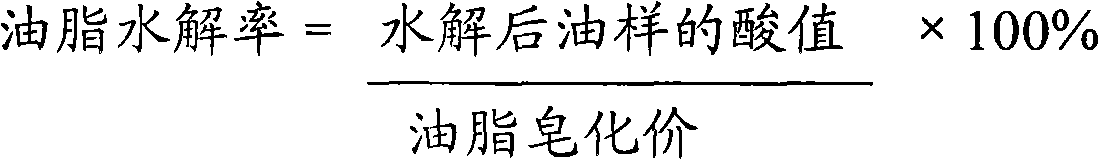

Embodiment 1

[0058] Add 2 grams of commercially available Koufu brand soybean oil into a 50 ml Erlenmeyer flask with a ground port stopper, then add 1.2 ml of enzyme solution prepared with pH6-pH7 phosphate buffer solution (the weight ratio of oil to water is 1: 0.6, and the enzyme powder is Lipase powder produced by Wuxi Enzyme Preparation Factory, enzyme activity 80U / ml), the pH of the aqueous phase was adjusted to 6.0 with 2N NaOH solution, and the shaking reaction was carried out at 40°C and 130 rpm for 36h. The acid value of the obtained fat hydrolyzate was determined by acidity analysis method to be 125 mgKOH / g oil, and the hydrolysis rate was calculated to be 62.5% according to the above method.

[0059] The obtained hydrolyzate was acidified with 2N sulfuric acid to make the pH value of the water phase reach 4.5, then heated to 68°C, allowed to stand for stratification, and the water phase (sweet water containing glycerin) was released to obtain crude fatty acid containing a small a...

Embodiment 2

[0063] Add 10 grams of palm oil sold under the trade name palm oil by Qinhuangdao Jinhai Cereals and Oils Industry Co., Ltd. in a 250 ml conical flask with a stopper, then add 0.1 g NOVOZYM435 (enzyme activity 10000 PLU / g, PLU / g refers to every 1g enzyme The propyl laurate unit that generates), adjust the weight ratio of oil and water with the phosphate buffer solution of pH6-7 to be 1: 0.2, add sodium stearate 1.4g, the pH of aqueous phase is adjusted to 5.7 with 2N NaOH solution, in 45°C, 130 rpm shaking reaction for 30h. The acid value of the hydrolyzed solution obtained was determined by acidity analysis method to be 162 mgKOH / g oil, and the hydrolysis rate was calculated to be 81% according to the above method.

[0064] The obtained hydrolyzate was acidified with 3N sulfuric acid to make the pH value of the water phase reach 4.5, then heated to 70°C, allowed to stand for stratification, and released the water phase (sweet water containing glycerin) to obtain crude fatty a...

Embodiment 3

[0067] Add 1000 grams of soybean acidified oil sold by Qinhuangdao Jinhai Cereals and Oils Industry Co., Ltd. into a 2000ml four-port reactor, add 600ml of enzyme solution prepared with pH6-pH7 phosphate buffer solution (the weight ratio of oil to water is 1:0.6, and the enzyme powder is Wuxi Lipase powder produced by the enzyme preparation factory, enzyme activity 80U / ml), sodium stearate 140g, use 2N NaOH solution to control the pH of the aqueous phase to 6.5-7.0, and react at 40°C and 100 rpm for 36h. The acid value of the obtained fat hydrolyzate was determined by acidity analysis method to be 143 mgKOH / g oil, and the hydrolysis rate was calculated according to the above method to be 71.5%.

[0068] The obtained hydrolyzate was acidified with 3N sulfuric acid to make the pH value of the water phase reach 4.5, then heated to 65°C, allowed to stand for stratification, and the water phase (sweet water containing glycerin) was released to obtain crude fatty acid containing a sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com