Method for formulating concrete with permanent stability

A durable concrete and preparation method technology, applied in the field of building materials, can solve problems such as inability to directly reflect chemical, physical and mechanical properties, and poor practicability, so as to reduce project cost, maintenance and repair costs, social benefits and environmental benefits High, improve the effect of anti-cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

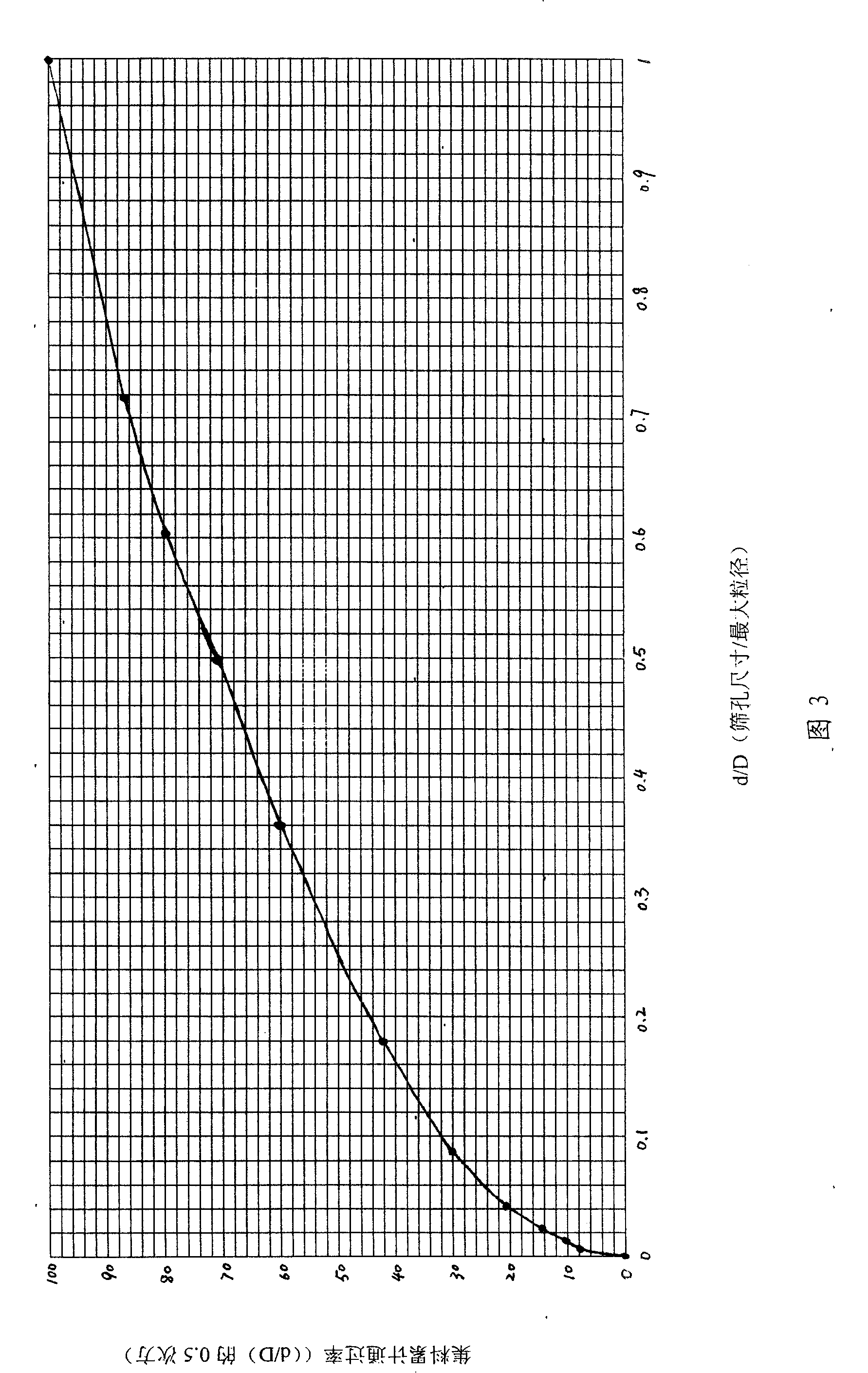

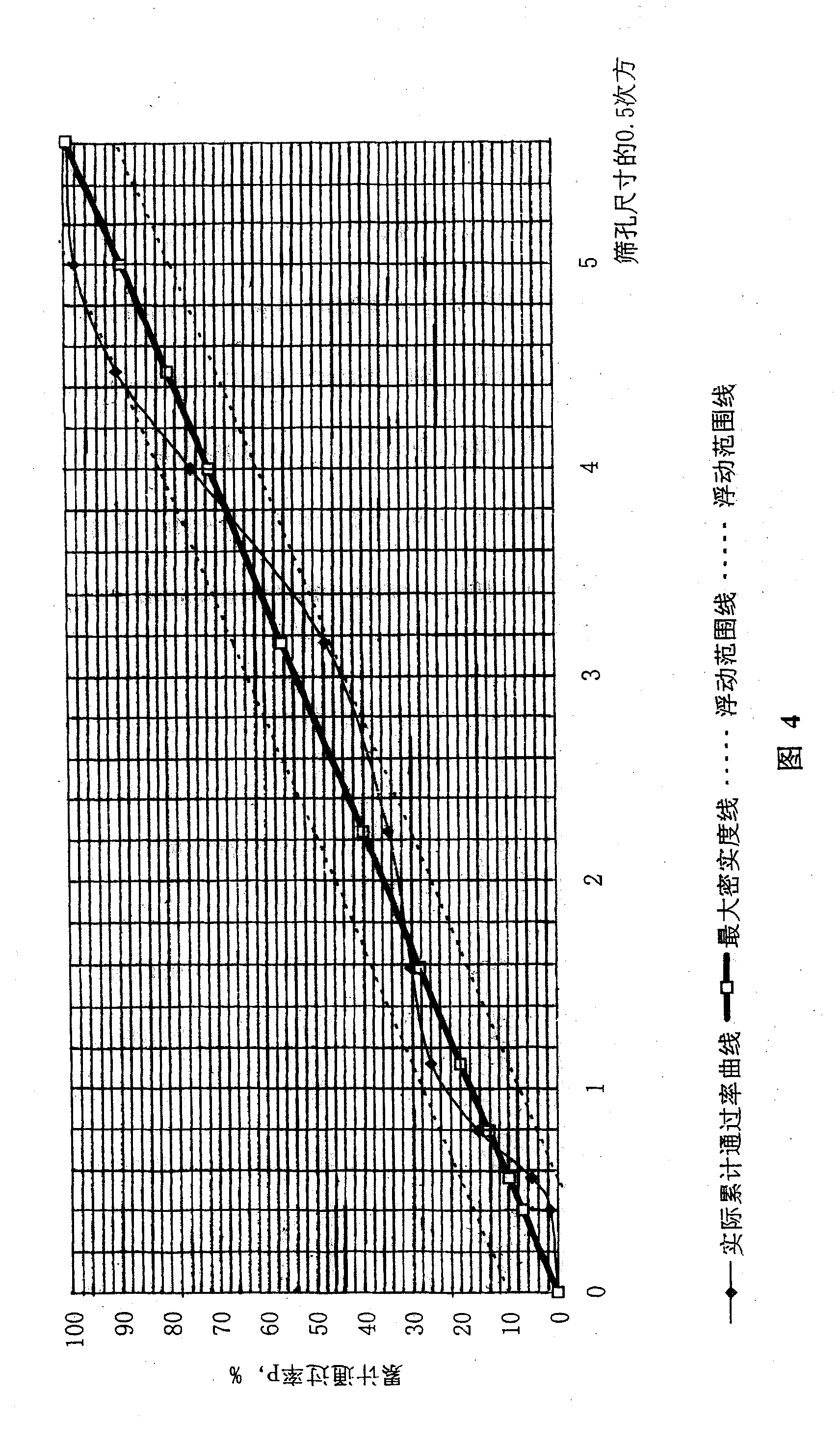

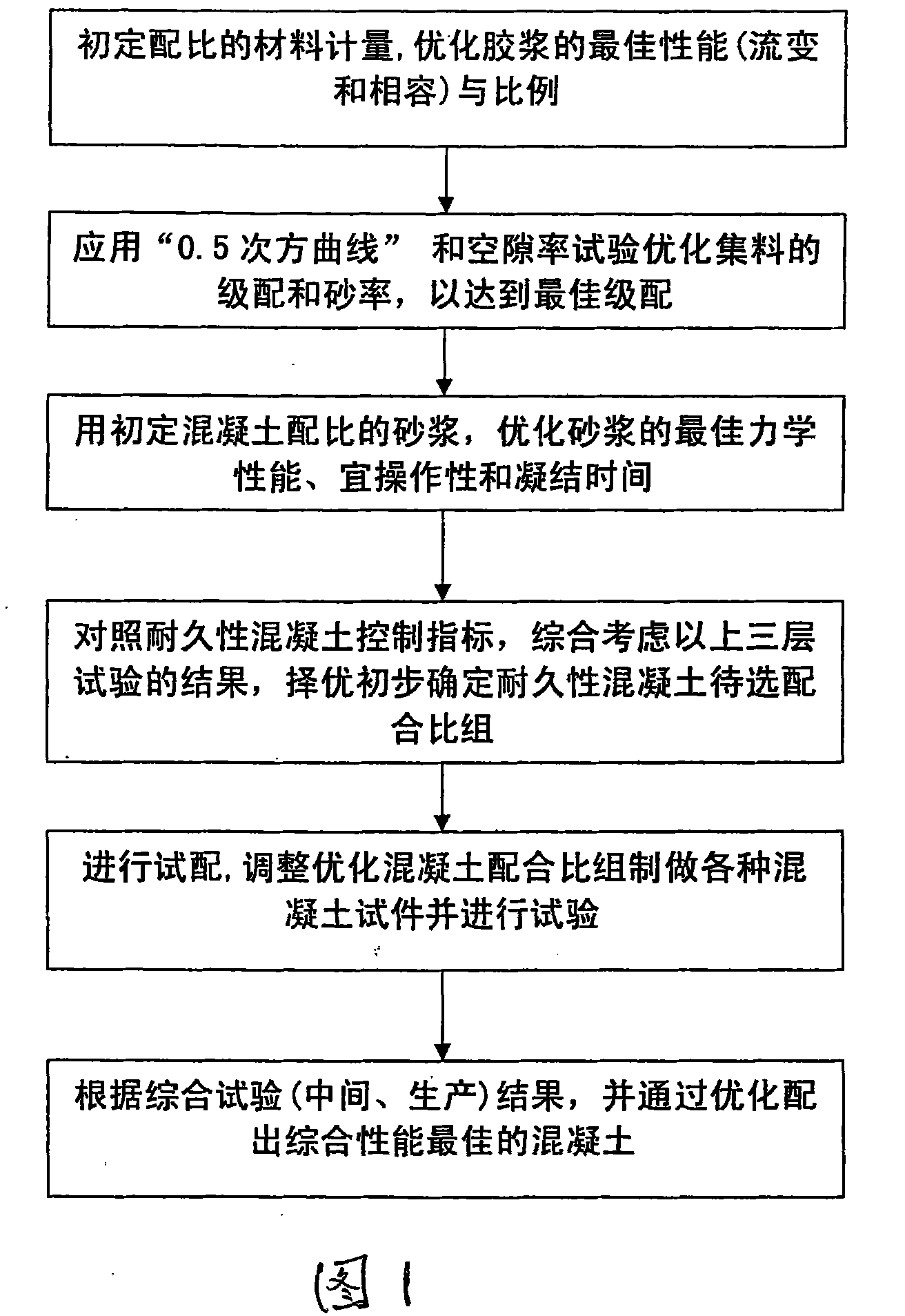

[0024] Embodiment: a kind of preparation method of durable concrete is (see Fig. 1-4): first, preliminary design durable concrete mix ratio, wherein in every cubic meter of concrete, the quality of cementitious material is 380kg, and the quality of sand is 670kg , the quality of gravel is 1170kg, and the quality of water is 150kg; Said cementitious material contains cement, fly ash, slag powder, water reducer and air-entraining agent, and wherein cement accounts for 80% of cementitious material total amount, Fly ash accounts for 8% of the total cemented material, slag powder accounts for 12% of the total cemented material, water reducing agent accounts for 1.5% of the total cemented material, and air-entraining agent accounts for 0.008% of the total cemented material ; Then mix cement, fly ash, slag powder, water, water reducing agent, and air-entraining agent according to the above ratio, and observe the viscosity, setting time, etc. If there is no abnormality, it can be confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com