Method for producing O18 water and deuterium deficient water

A technology of deuterium-depleted water and raw water, applied in chemical instruments and methods, water, heavy water, etc., can solve problems such as the inability to achieve deuterium content below 50 ppm, light components are not paid attention to, and achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

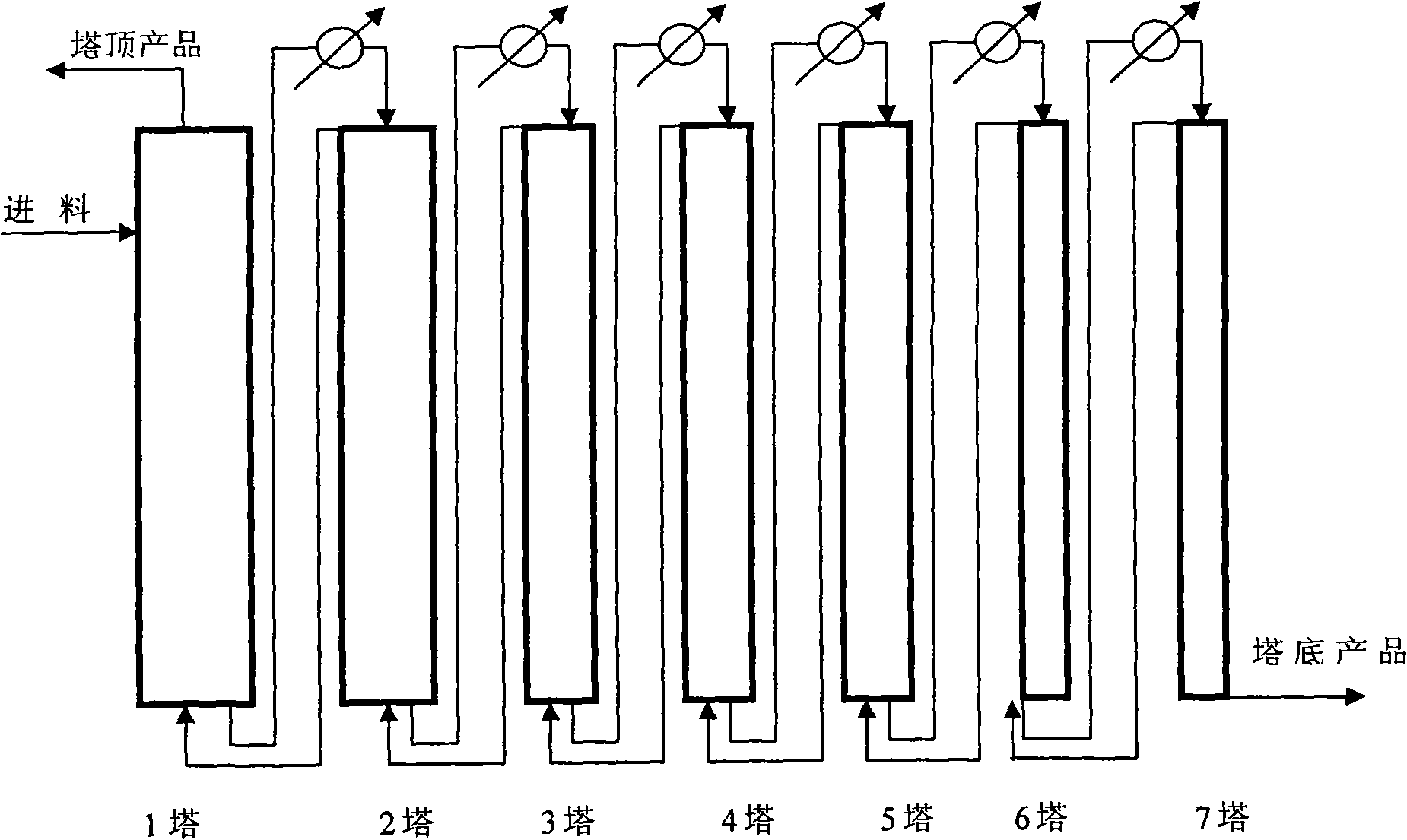

Embodiment 1

[0035] The rectification tower is manufactured by Changshu Kehui Bioengineering Co., Ltd. The material used is a stainless steel tower body, and the filler is copper mesh with surface oxidation treatment, the same below. The feed rate is 120Kg / h, the deuterium concentration is 150ppm, and the oxygen 18 concentration is 0.198%. The head pressure of tower 1 is controlled to be 75mmHg, the bottom pressure of the tower is 230mmHg, the average temperature in the tower is 56°C, the liquid phase flow rate in the rectification section is 600Kg / h, and the gas phase flow rate in the rectification section is 719.994Kg / h. The liquid phase flow rate in the column of the stripping section is 720Kg / h, and the gas phase flow rate is 719.994Kg / h. The feeding position is the 9th plate (from top to bottom), and the pressure at the head of the second tower is 75mmHg, the bottom pressure is 230mmHg, the average temperature in the tower is 57°C, and the liquid phase flow rate in the stripping secti...

Embodiment 2

[0037] The feed rate is 30Kg / h, wherein the concentration of deuterium is 150ppm, and the concentration of oxygen 18 is 0.198%. The head pressure of tower 1 is controlled to be 75mmHg, the bottom pressure of the tower is 230mmHg, the average temperature in the tower is 56°C, the liquid phase flow rate in the rectification section is 690Kg / h, and the gas phase flow rate in the rectification section is 719.994Kg / h. The liquid phase flow rate in the column of the stripping section is 720Kg / h, and the gas phase flow rate is 719.994Kg / h. The feeding position is the 37th plate (from top to bottom), and the pressure at the head of the second column is controlled to be 75mmHg, the pressure at the bottom of the column is 230mmHg, the average temperature in the column is 57°C, and the liquid phase flow rate in the stripping section is 600Kg / h. The gas phase flow rate is 599.994Kg / h. Control the pressure at the head of the 3rd column to be 75mmHg, the pressure at the bottom of the colum...

Embodiment 3

[0039]The feed rate is 28.8Kg / h, the deuterium concentration is 150ppm, and the oxygen 18 concentration is 0.198%. The head pressure of tower 1 is controlled to be 75mmHg, the bottom pressure of the tower is 230mmHg, the average temperature in the tower is 56°C, the liquid phase flow rate in the rectification section is 691.2Kg / h, and the gas phase flow rate in the rectification section is 719.994Kg / h. The liquid phase flow rate in the column of the stripping section is 720Kg / h, and the gas phase flow rate is 719.994Kg / h. The feeding position is the 39th plate (from top to bottom), the pressure at the head of the second tower is 75mmHg, the bottom pressure is 230mmHg, the average temperature in the tower is 57°C, and the liquid flow rate in the stripping section is 600Kg / h. The gas phase flow rate is 599.994Kg / h. Control the pressure at the head of the 3rd column to be 75mmHg, the pressure at the bottom of the column to be 235mmHg, the average temperature in the column to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com