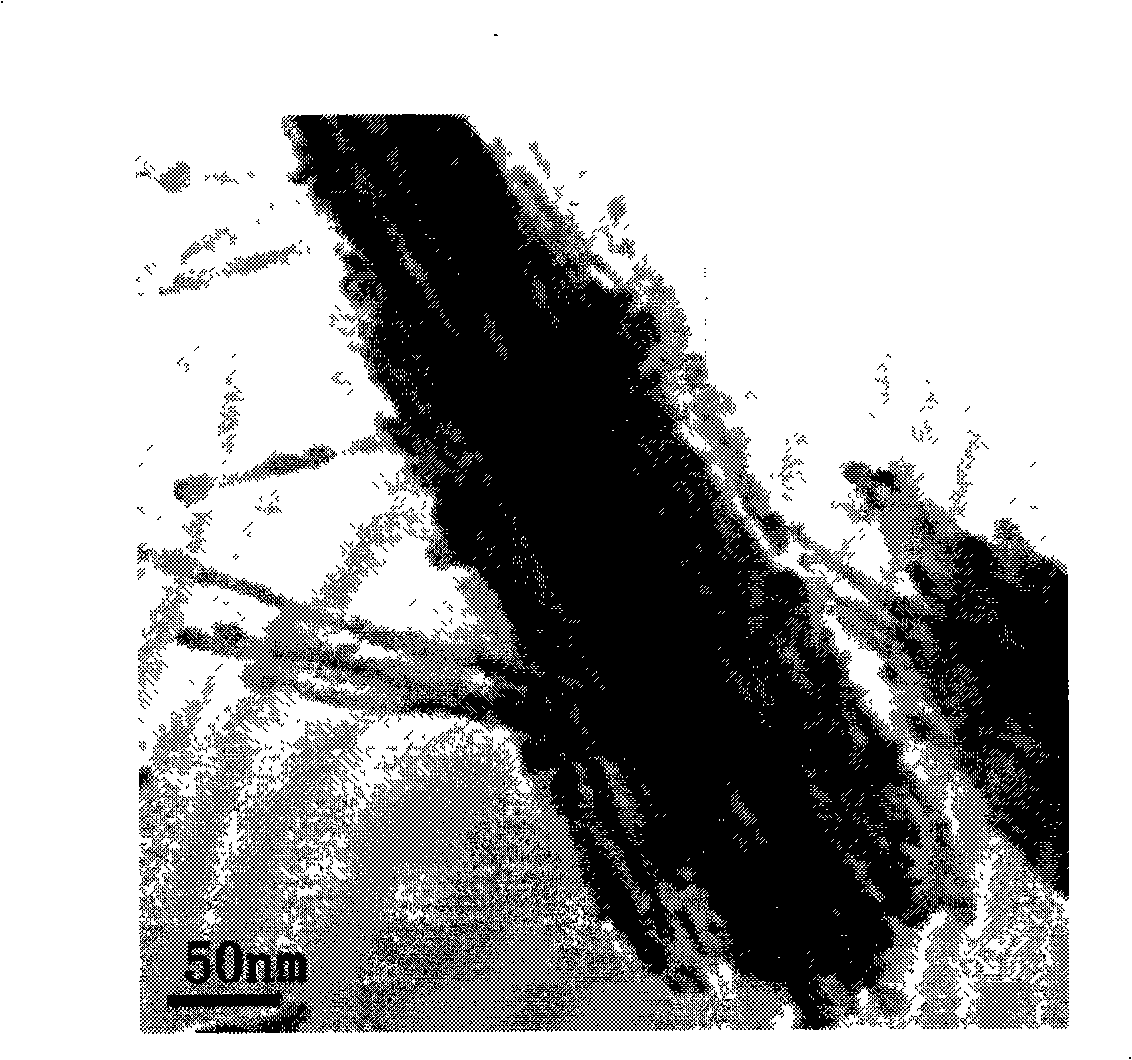

Method for preparing biological activity glass nano-fibre cluster

A bioactive glass and nanofiber technology is applied in the field of inorganic powder preparation in the field of biomedical materials, and can solve the problems of easy introduction of impurities and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) First prepare a certain amount of ethyl orthosilicate and triethyl phosphate into solution A; mix a certain amount of calcium nitrate tetrahydrate, hydrochloric acid, deionized water, and Tween template into solution B, and adjust with hydrochloric acid The pH of the solution is 1, and the template concentration is 0.5×10 -2 mol / L; Slowly add B solution to A solution and stir well to obtain a transparent, uniform and stable sol; Among them, ethyl orthosilicate, triethyl phosphate and calcium nitrate tetrahydrate account for the total moles of the three substances The percentages are respectively 60%, 4% and 36%, and the molar ratio of deionized water to ethyl orthosilicate is 12:1;

[0021] (4) The sol obtained in step (3) is statically aged for 4 days at room temperature to allow the hydrolysis-polycondensation reaction to proceed sufficiently to form a wet gel;

[0022] (5) Put the wet gel obtained in step (4) in a drying oven at 140°C for 2 days, and obtain a dry gel...

Embodiment 2

[0025] (1) First prepare a certain amount of ethyl orthosilicate and triethyl phosphate into solution A; mix a certain amount of calcium nitrate tetrahydrate, hydrofluoric acid, deionized water, and Tween template into solution B, use Hydrofluoric acid adjusts the pH of the solution to 3, and the template concentration is 1.5×10 -2 mol / L; Slowly add B solution to A solution and stir well to obtain a transparent, uniform and stable sol; Among them, ethyl orthosilicate, triethyl phosphate and calcium nitrate tetrahydrate account for the total moles of the three substances The percentages are 70%, 4% and 26% respectively, and the molar ratio of deionized water to ethyl orthosilicate is 11:1;

[0026] (4) The sol obtained in step (3) is statically aged for 5 days at room temperature to allow the hydrolysis-polycondensation reaction to proceed sufficiently to form a wet gel;

[0027] (5) Place the wet gel obtained in step (4) in a drying oven at 80°C for 3 days, and obtain a dry gel af...

Embodiment 3

[0030] (1) First prepare a certain amount of ethyl orthosilicate and triethyl phosphate into solution A; mix a certain amount of calcium nitrate tetrahydrate, ammonia, deionized water, and Tween template into solution B, and use alkaline The catalyst adjusts the pH value of the solution to 10, and the template concentration is 3×10 -2 mol / L; Slowly add B solution to A solution and stir well to obtain a transparent, uniform and stable sol; Among them, ethyl orthosilicate, triethyl phosphate and calcium nitrate tetrahydrate account for the total moles of the three substances The percentages are respectively 80%, 4% and 16%, and the molar ratio of deionized water to ethyl orthosilicate is 8:1;

[0031] (4) The sol obtained in step (3) is statically aged for 7 days at room temperature to allow the hydrolysis-polycondensation reaction to proceed sufficiently to form a wet gel;

[0032] (5) Put the wet gel obtained in step (4) in a drying oven at 100°C for 2 days, and dry gel is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com