Silicon wet method corrosion for manufacturing multiple stage micro-reflector

A technology of micro-reflector and wet etching, which is applied in the photoplate process of mirrors and patterned surfaces, optics, etc., and can solve problems such as difficulty in ensuring horizontal accuracy, difficulty in accurately controlling corrosion or etching depth, poor accuracy and repeatability, etc. , to achieve the effects of high flatness, improved production efficiency and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

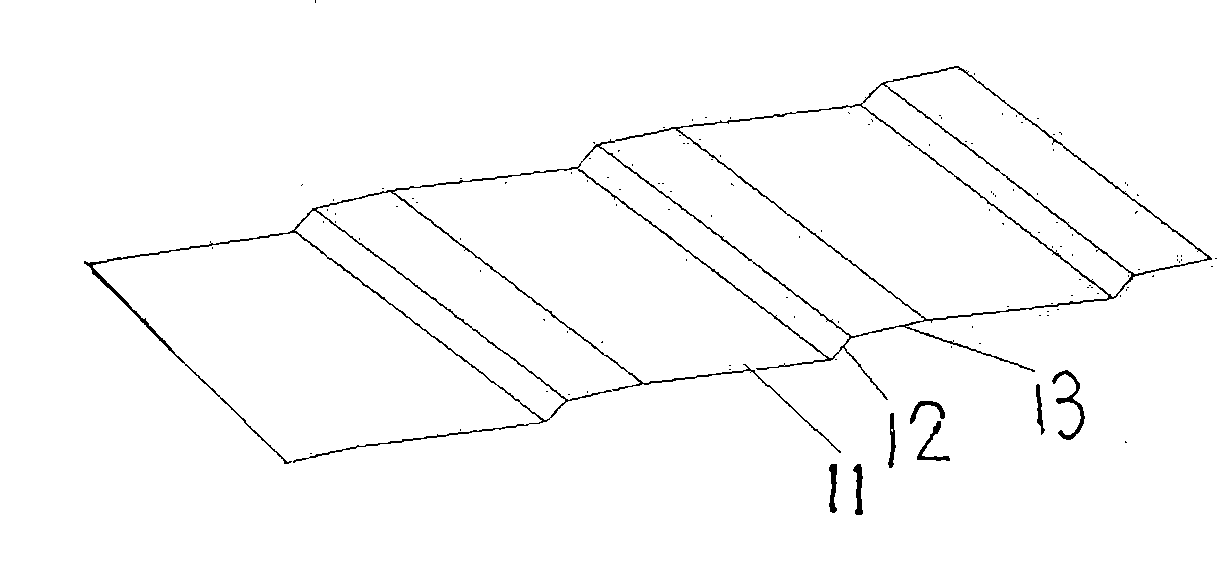

[0015] Combine below figure 1 with figure 2 The method of fabricating multi-level micro-mirrors by wet etching of silicon is introduced in detail.

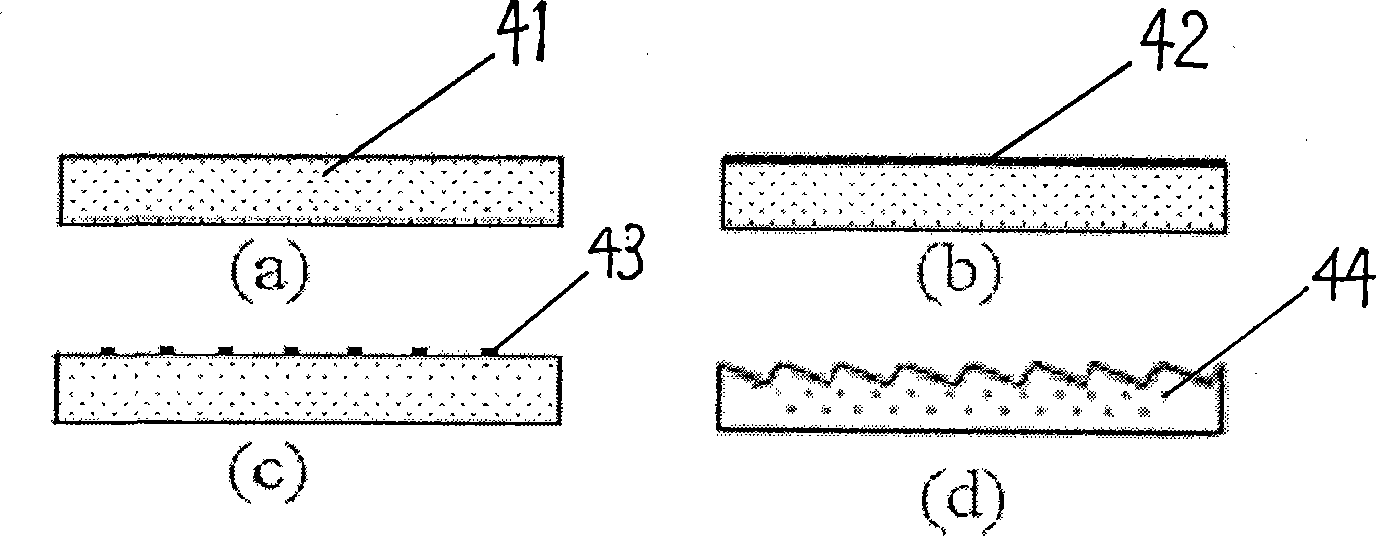

[0016] A, select the silicon chip 41 that upper surface and (111) face deviate certain angles as multistage microreflector material, polish its upper surface; Parameter setting, cleaning the silicon wafer after polishing.

[0017] b. Design of photolithographic plate: design the photolithographic plate according to the design parameters of the multi-stage micro-reflector, the layout is bright and dark stripes; the width of the dark stripes is figure 2 The width of the midplane 13, the bright stripe width is figure 2 The width of the reflection surface 11 of the mid-level micro-mirror plus the projection of the truncated surface 12 on the upper surface of the silicon wafer 41 . Such as figure 2 As shown, both the reflective surface 11 and the truncated surface 12 are (111) surfaces of the silicon wafer, the angle between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com