Electromagnetic valve

A solenoid valve and valve body technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problems of shortening the service life of the solenoid valve, short circuit of the coil and the diode, increasing the economic burden of the user, etc., to improve the quality stability and Durability, reducing quality failures, improving impact resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

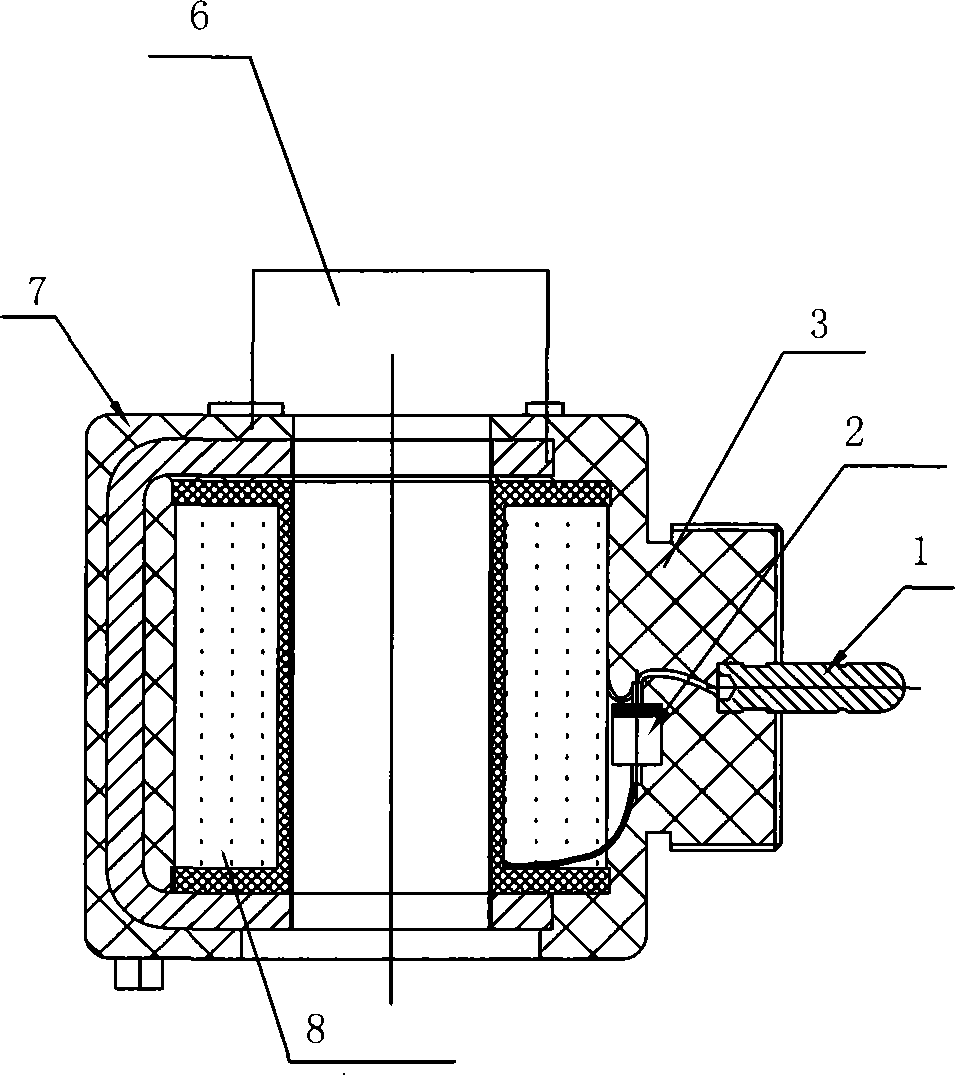

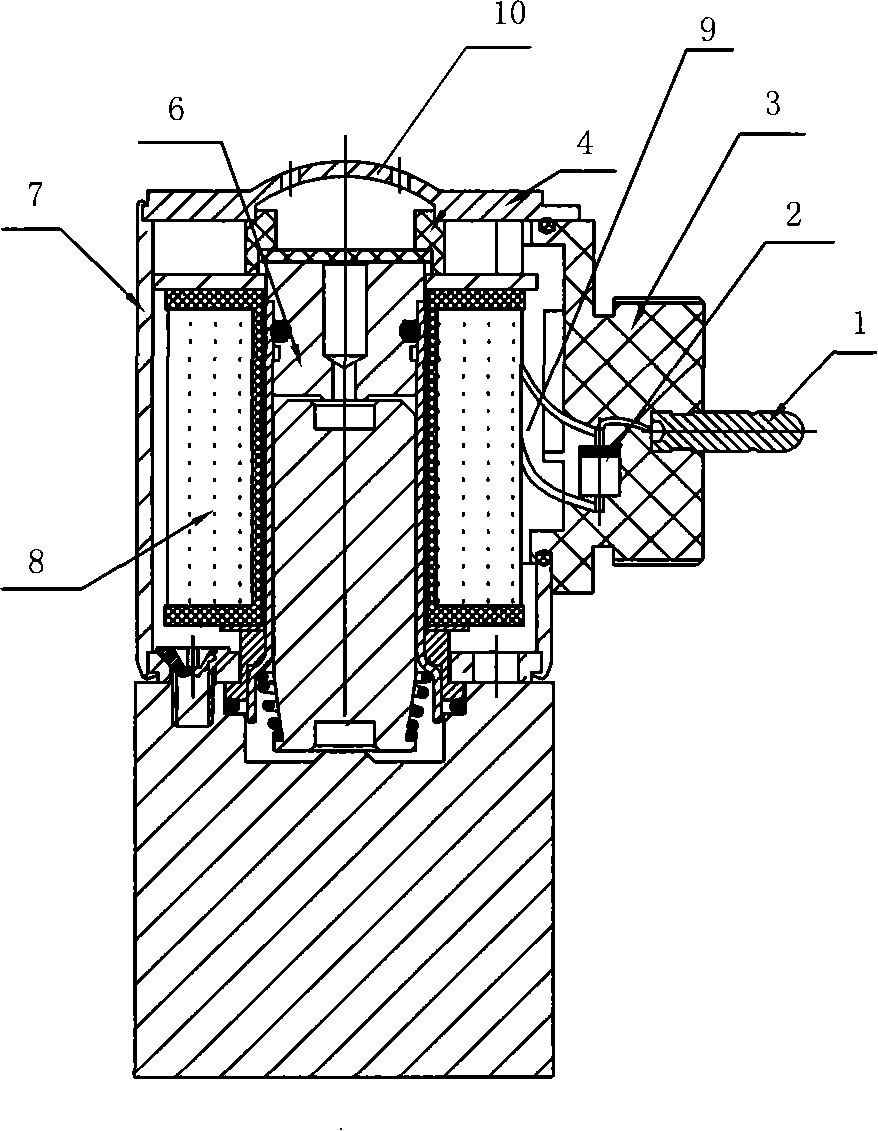

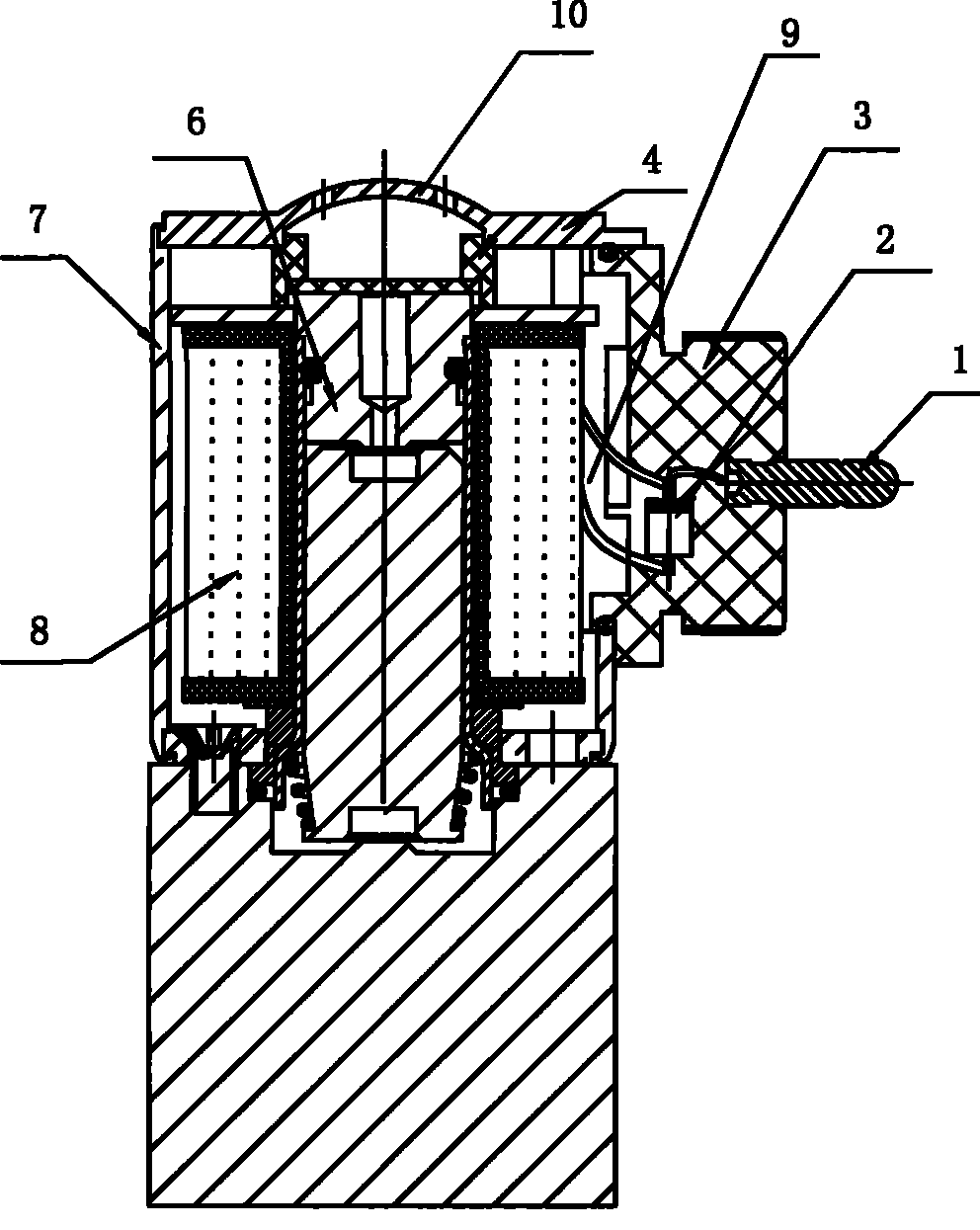

[0022] refer to figure 2 , the solenoid valve in this embodiment, this kind of solenoid valve includes a valve body and a coil package arranged on the valve body, the coil package includes a housing 7, an exhaust cover 6, and a coil package arranged in the housing 7 Various components constituting the solenoid valve, such as coil 8, insert 1 and diode 2, the exhaust cover 6 is arranged inside the housing 7, and a cooling chamber 9 is provided between the insert seat and the coil, The heat dissipation performance of the coil and the diode is effectively improved, thereby improving the quality stability and durability of the product. Said housing 7 is provided with a position that can be opened to the housing when parts in the housing are damaged. This position is the top cover 4, that is, the top cover 4 can be opened. The present invention passes the top cover 4 through the housing. The edge of 7 is fixed in position, and finally fastened on the housing 7 by fasteners, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com