Method for preparing poly(hexamethylene) hydrochloride

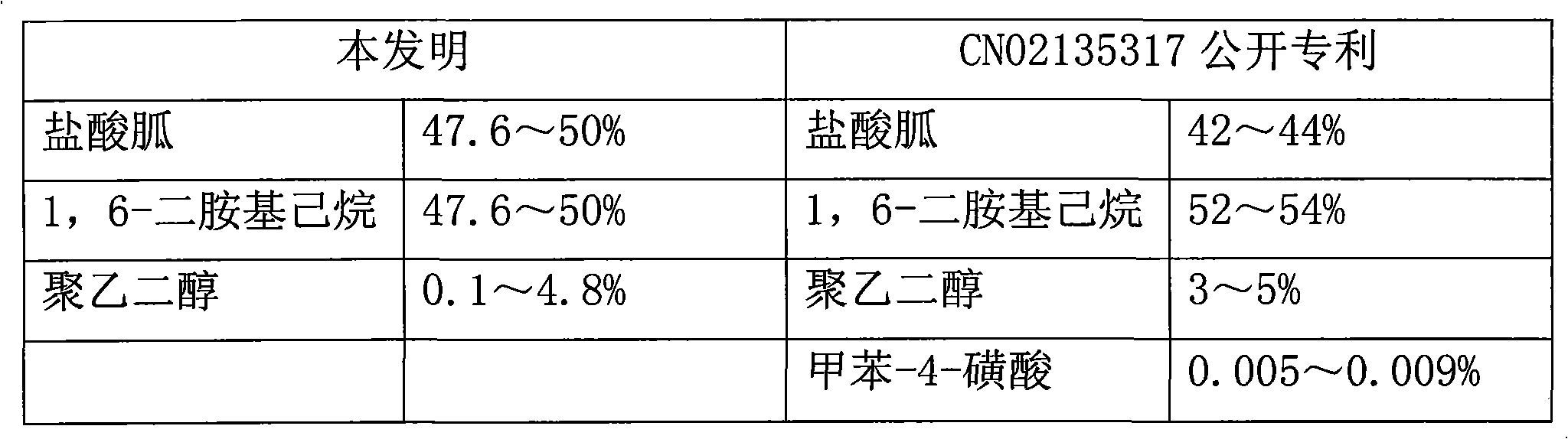

A technology of polyhexamethylene guanidine hydrochloride and guanidine hydrochloride, which is applied in the fields of botanical equipment and methods, chemicals for biological control, animal repellants, etc., can solve the problems of low degree of polymerization, narrow pH range, Short sterilization period and other problems, to achieve the effect of strong water solubility, wide sterilization range, and reducing the trouble of replacing fungicides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] The schematic diagram of the technological process as shown in Figure 1 is operated:

[0017] a. Raw material ratio: the mass ratio of guanidine hydrochloride and 1,6-diaminohexane is 1: 1,

[0018] b. Put the well-proportioned raw materials into the reactor, stir and heat until completely dissolved and fully mixed, then raise the temperature to 150°C, add polyethylene glycol during the heating process, the amount of polyethylene glycol used is guanidine hydrochloride and 1, 6 5% of the total mass of diaminohexane;

[0019] c. After the temperature in the reactor was kept at 150°C for 2 hours, there was no NH in the reactor 3 Emit, the reaction finishes, obtains product polyhexamethylene guanidine hydrochloride 1#.

example 2

[0021] The schematic diagram of the technological process as shown in Figure 1 is operated:

[0022] a. raw material ratio: the mass ratio of guanidine hydrochloride and 1,6-diaminohexane is 1: 1,

[0023] b. Put the well-proportioned raw materials into the reactor, stir and heat until completely dissolved and fully mixed, then raise the temperature to 200°C, add polyethylene glycol during the heating process, the amount of polyethylene glycol used is guanidine hydrochloride and 1, 0.1% of the total mass of 6 diaminohexane;

[0024] c. After the temperature in the reactor was kept at 200°C for 3 hours, there was no NH in the reactor 3 Emit, the reaction finishes, obtains product polyhexamethylene guanidine hydrochloride 2#.

example 3

[0026] The schematic diagram of the technological process as shown in Figure 1 is operated:

[0027] a. raw material ratio: the mass ratio of guanidine hydrochloride and 1,6-diaminohexane is 1: 1,

[0028] b. Put the well-proportioned raw materials into the reactor, stir and heat until completely dissolved and fully mixed, then raise the temperature to 120°C, add polyethylene glycol during the heating process, the amount of polyethylene glycol used is guanidine hydrochloride and 1, 3% of the total mass of 6 diaminohexane;

[0029] c. After keeping the temperature in the reactor at 120°C for 2.5 hours, there is no NH in the reactor 3 Emit, the reaction finishes, obtains product polyhexamethylene guanidine hydrochloride 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com