Processing die of dual-color plastic chair and its processing method

A technology for two-color plastics and processing molds, used in household appliances, other household appliances, household components, etc., can solve the problems of complex equipment manufacturing and large investment, achieve equipment investment saving, improve product quality, improve production efficiency and product quality. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

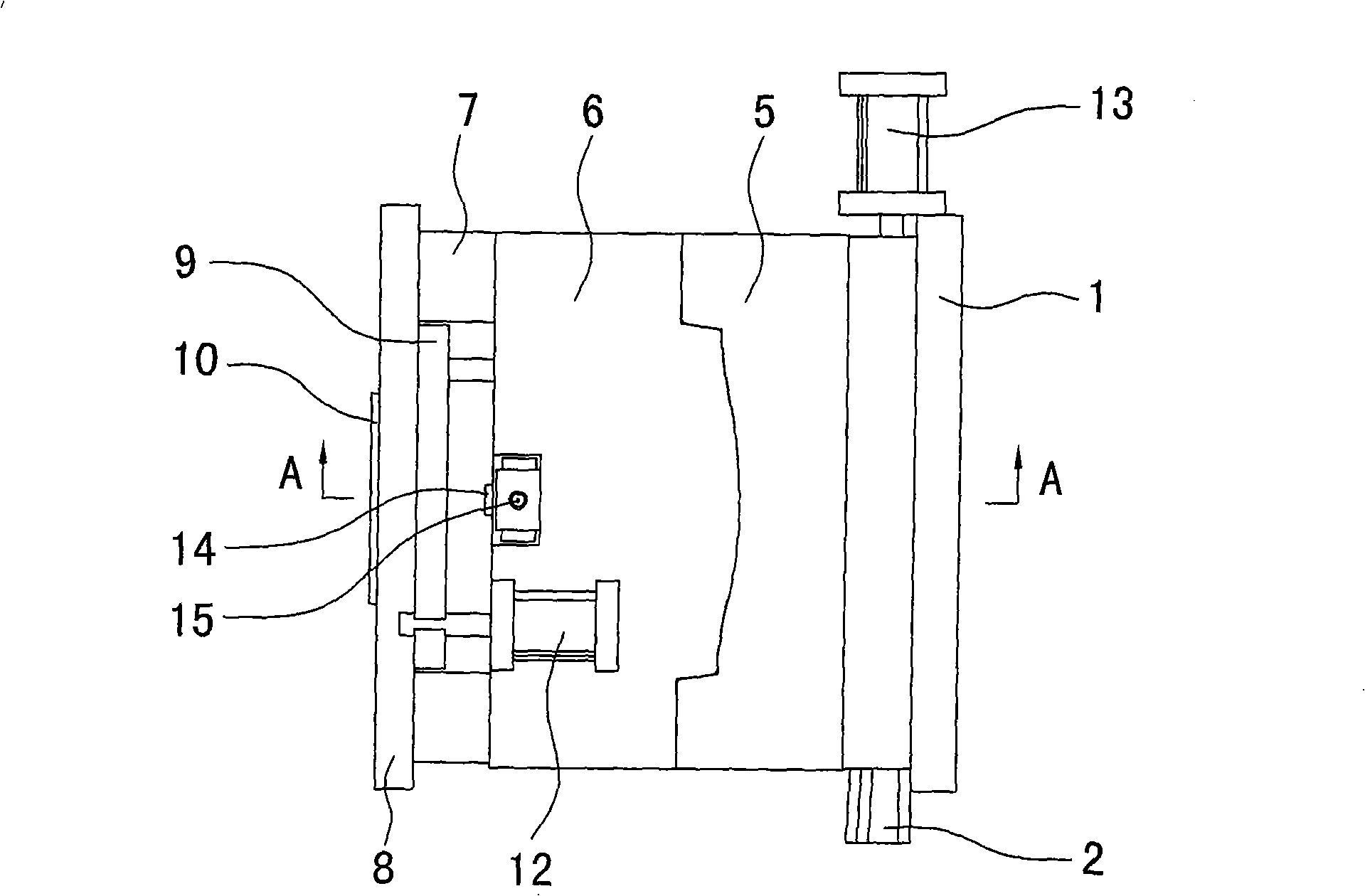

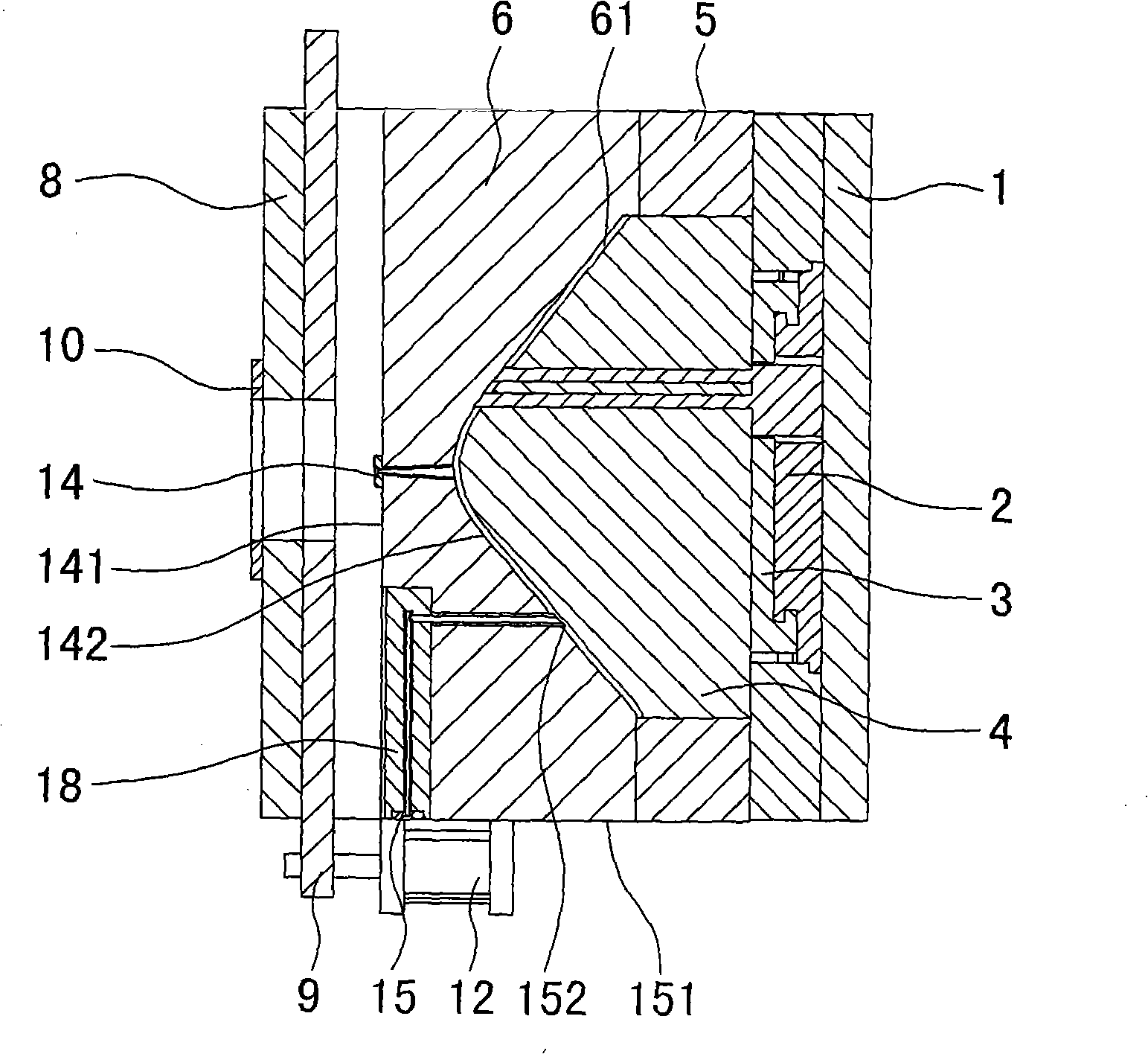

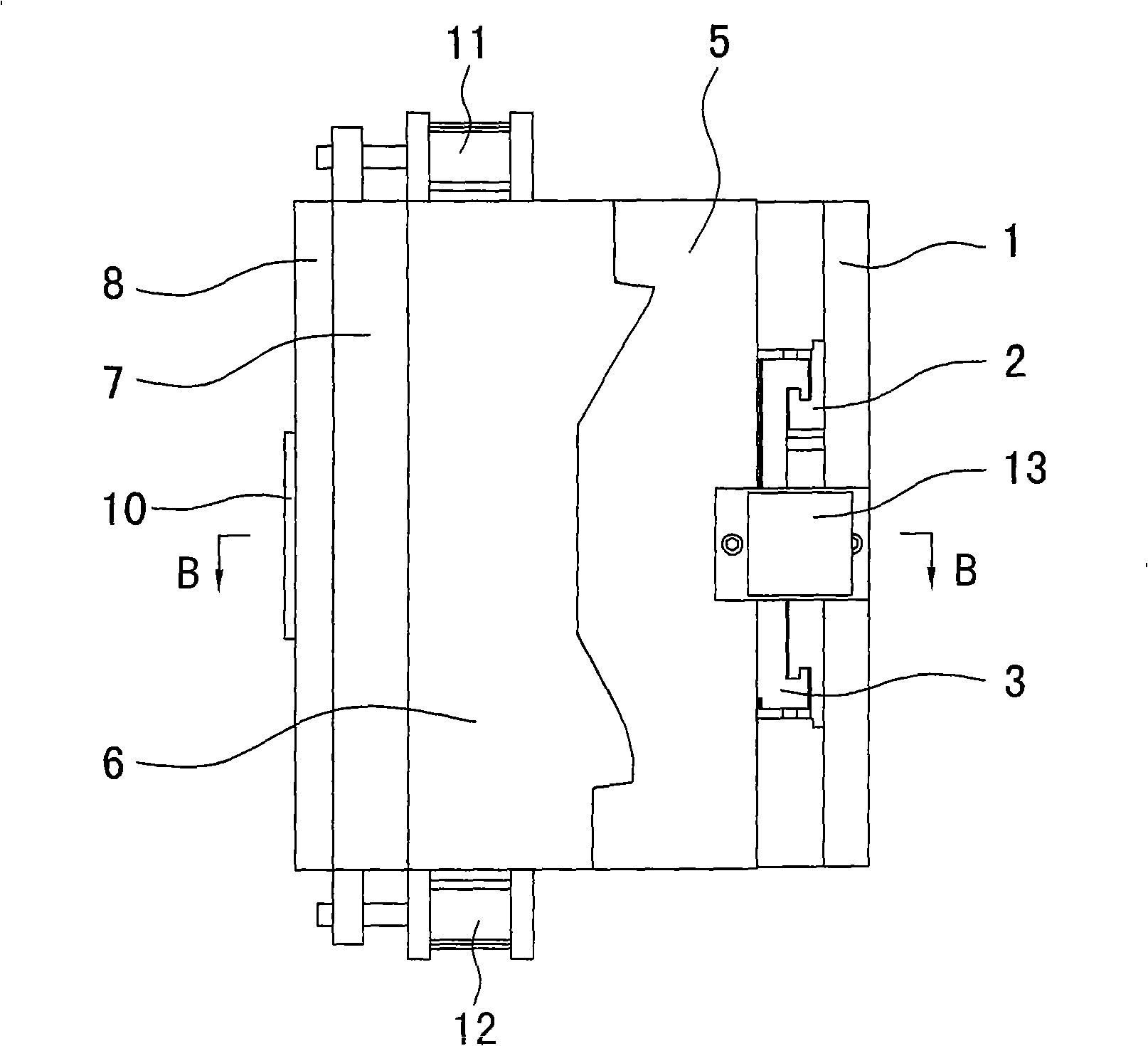

[0024] The present invention relates to the processing mold of two-color plastic chair, as Figure 1-Figure 4 As shown, it is composed of pouring system, cavity and core, demoulding system, bottom plate 1, 8, mold foot 7 and other fixing and installation accessories. The bottom plate 8 is equipped with a positioning ring 10, which is convenient for positioning with the nozzle on the injection molding machine. There is a mold cavity 61 of the product between the cavity and the core, which is characterized in that there is a movable insert 4 in the core 5, and the movable insert 4 is connected with the inclined slider A 3, which can be fastened by screws, and the inclined slider A 3 is in contact with the oblique slider B 2, and the groove and tenon connection can be used to make the two oblique sliders move relative to each other, and the oblique slider B 2 is driven by the push cylinder 13; the cavity has two gates 14, 15, The opening of the first gate 14 is located at the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com