Method for improving quality of the tobacco leaf expanded cut stem by microorganism enzyme

A microbial enzyme and biological enzyme technology, which is applied in the field of tobacco cut stem treatment, can solve the problems of increased woodiness, decreased energy, and hindering the effective utilization of cut stems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

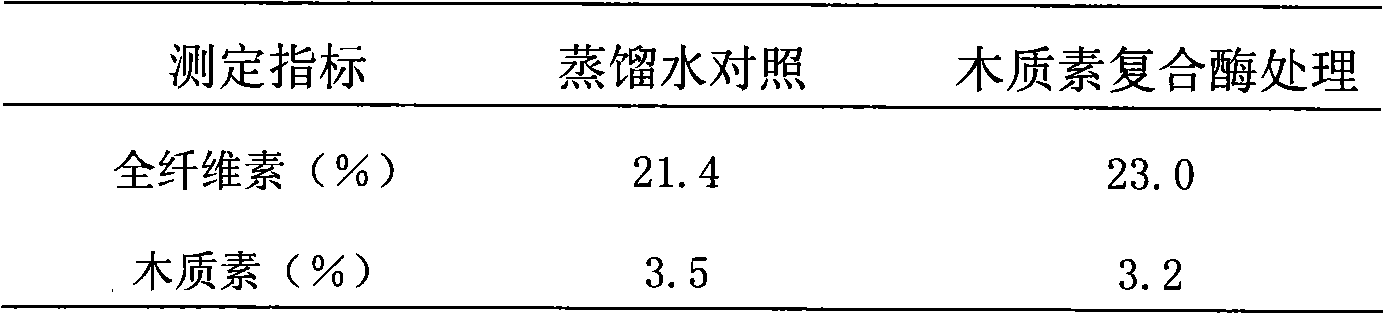

Examples

Embodiment 1

[0038] 1. Biological enzyme source: the enzyme-producing strain is Aspergillus niger with the preservation number CGMCC0571.

[0039] 2. Activation and cultivation of Aspergillus niger:

[0040] Aspergillus niger strains were activated and cultivated in potato sucrose medium, then inserted into sterilized seed medium, and incubated at 28°C, 250r min -1 Cultivate on a shaking table for 24 hours; insert the seed liquid into a sterilized 500ml shake flask (containing 100ml of enzyme-producing culture solution) according to 10% inoculation amount, and carry out enzyme-producing culture at 25°C for 96 hours to obtain a fermentation broth.

[0041] Among them: main components of seed medium (g L -1 ): Glucose 50, KCl 0.2, KH 2 PO 4 0.15, MgSO 4 ·7H 2 O0.12, (NH 4 ) 2 HPO 4 0.6, yeast extract 3, peptone 2. Main components of enzyme production medium: glucose 10g, ammonium tartrate 0.1g, MgSO 4 ·7H 2 O 0.5g, KH 2 PO 4 1g, Na 2 HPO 4 0.2g, MnSO 4 0.035g, CuSO 4 ·5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com