Energy-saving frying oven and its control method

A frying furnace and hob technology, which is applied in the field of automatic control frying furnace and its control, can solve problems such as wasting time, increasing air pollution, and poor operating environment for personnel, so as to achieve a comfortable operating environment, eliminate fire hazards, and eliminate fire hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

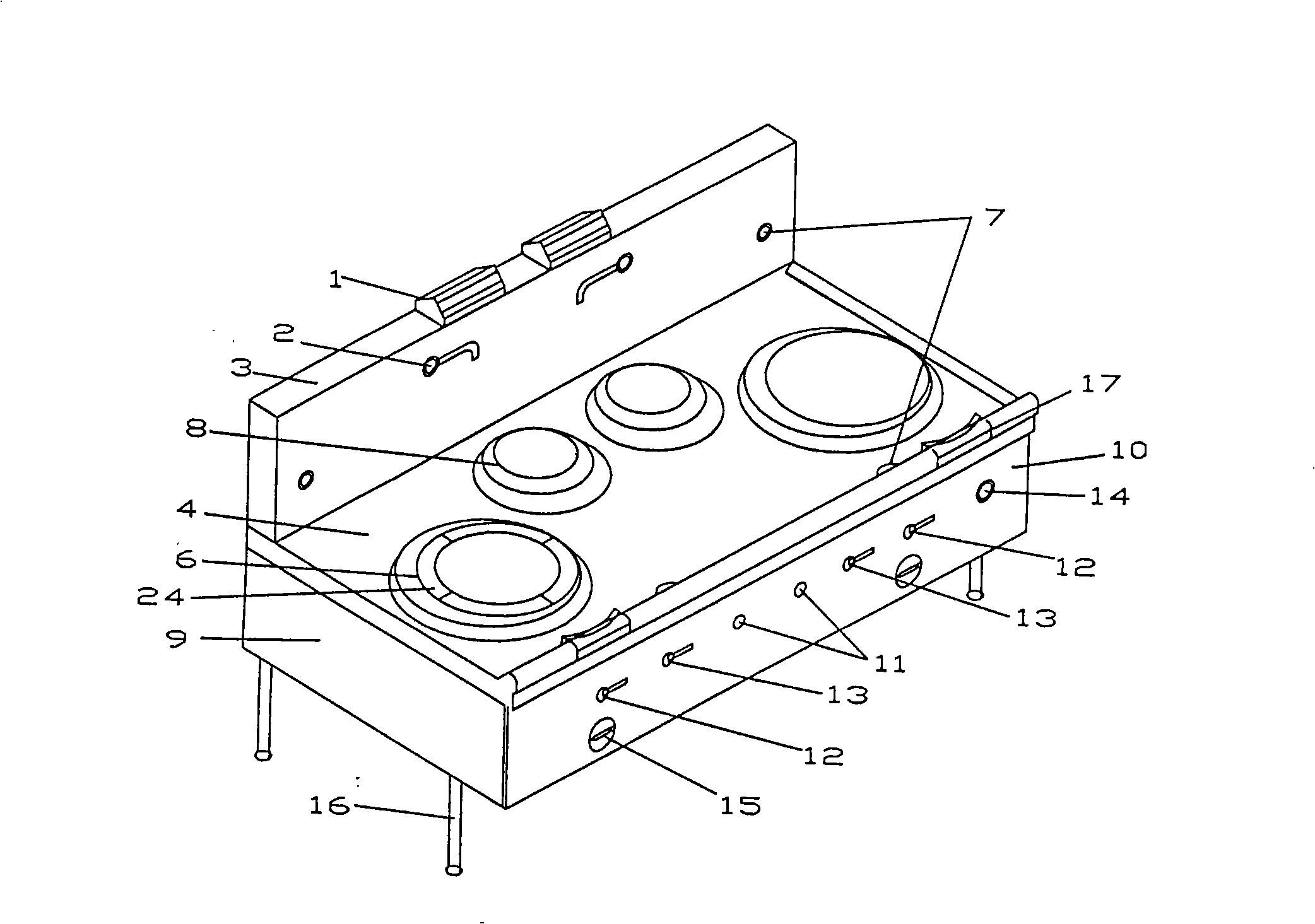

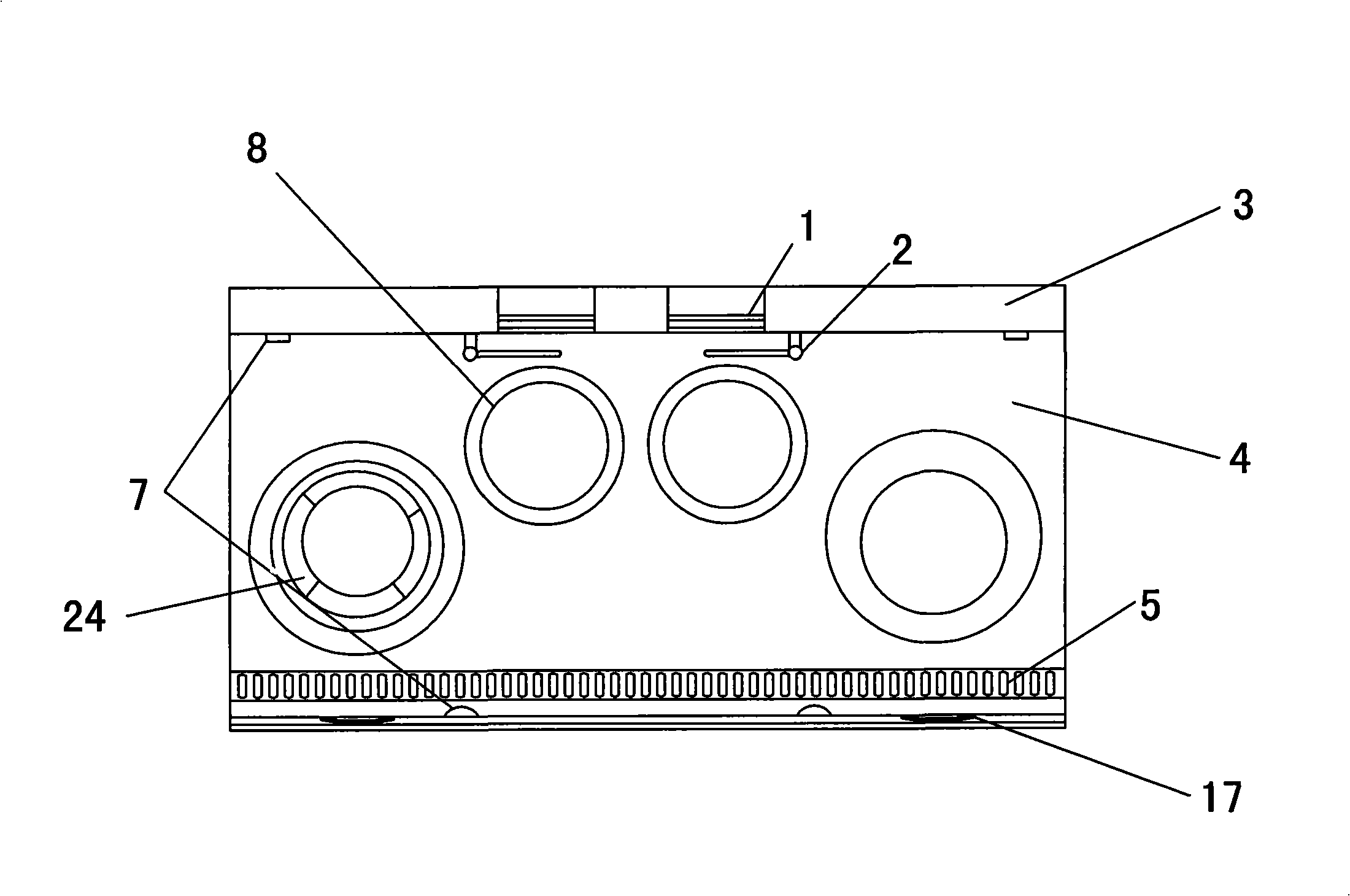

[0020] Such as Figure 1 to Figure 6 As shown, the present invention is an energy-saving frying furnace, the device includes a hob and an adjusting leg 16 supporting the hob, and the frying oven also includes a water supply part, an air supply part, a combustion part and an electric control part, wherein the water supply part includes The water inlet pipe installed on the right front of the frying furnace, the water inlet pipe is connected to the water valve 14 of the G1 / 2" gate valve, and connected to the swing faucet 2 through the bottom and back of the hob. The hob contains a back plate 3. The swing faucet 2 is installed on the backboard 3, the top of the backboard 3 is also installed with the flue gas 1 of the combustion exhaust gas; The valve 15 is connected to the burner of the combustion part through the air pipe 21. The blower adopts an outsourced 220V low-noise medium-pressure fan. The burner is composed of a nozzle 26, a gas distributor 27, a double-needle ignition n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com