Environmental protection type fuel energy-increasing additive agent

An environmentally friendly, additive technology, applied in the field of fuel additives, can solve problems such as inability to achieve, and achieve the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

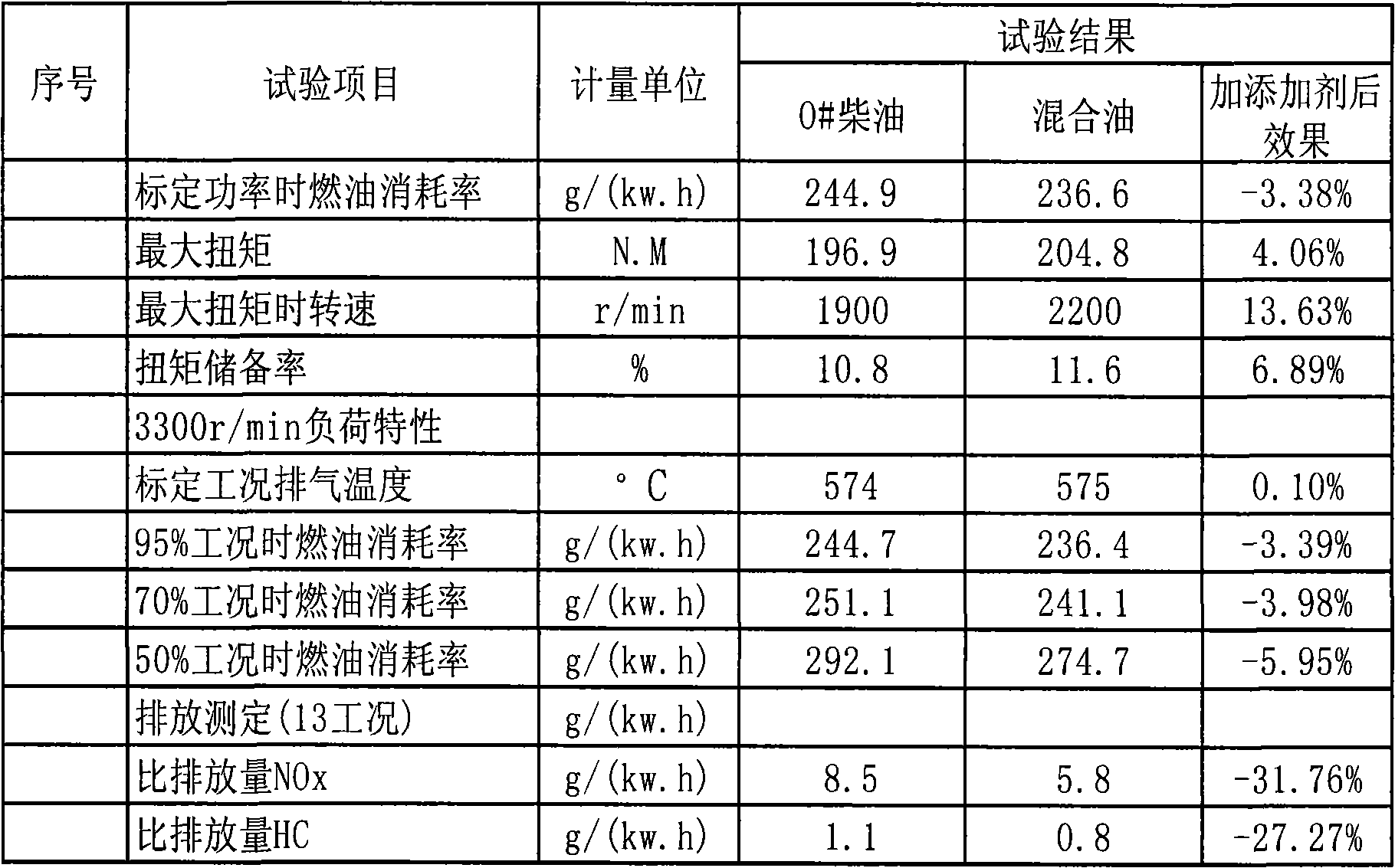

Examples

Embodiment 1

[0026] Recipe: aromatic hydrocarbon 100g (1%), triple makeup 100g (1%), reformed aromatic oil 100g (1%), mineral oil 3,500g (35%), PI-208 500g (5%), preservative 5 grams (0.5%) of antirust agent, 5 grams (0.5%) of catalyst agent, 5600 grams (56%) of naphtha;

[0027] The preparation method is as follows: 1) Pour 5600 grams of naphtha into the mixing reaction container, then pour 100 grams of aromatic hydrocarbons and 100 grams of three-peptide and reformed aromatic hydrocarbon oil into the naphtha, and slowly circulate through the variable-speed circulation gear pump Stir until uniform; 2) Pour 3,500 grams of mineral oil into another mixing reaction container, mix 5 grams of catalyst into the mineral oil, and through the cutting action of the high-speed pump, the catalyst is oil-dissolved and refined through the catalytic converter. 3) Pour the solution in the mixing reaction vessel 2 into container 1, add 500 grams of PI-208 and anti-corrosion and anti-rust agent, and then st...

Embodiment 2

[0029] Formula: aromatic hydrocarbon 490g (4.9%), triple makeup 450g (4.5%), reformed aromatic oil 530g (5.3%), mineral oil 5000g (50%), PI-2082,000g (20%) , 480 grams (4.8%) of anti-corrosion and anti-rust agent, 550 grams (5.5%) of catalyst, 500 grams (5%) of naphtha.

[0030] The preparation method is as follows: 1) Pour 500 grams of naphtha into a mixing reaction container, then pour 490 grams of aromatic hydrocarbons, 450 grams of triacetin and 530 grams of reformed aromatic hydrocarbon oil into the naphtha, and pass through the variable speed circulation gear pump Stir at a slow speed until uniform; 2) 5000 grams of mineral oil is poured into another mixed reaction vessel, 550 grams of catalyst is mixed in the mineral oil, the cutting action of the high-speed pump, and then the catalyst is carried out by the catalyst converter Oil-soluble refinement and stabilization treatment; 3) Pour the solution in the mixing reaction vessel 2 into the vessel 1, add 2000 grams of PI-2...

Embodiment 3

[0032] Formula: aromatic hydrocarbon 250g (2.5%), triple makeup 230g (2.3%), reformed aromatic oil 260g (2.6%), mineral oil 4500g (45%), PI-2081, 800g (18%), 200 grams (2.0%) of anti-corrosion and anti-rust agent, 260 grams (2.6%) of catalyst, 2,500 grams (25%) of naphtha.

[0033] The preparation method is as follows: 1) Pour 2700 grams of naphtha into the mixing reaction container, then pour 250 grams of aromatic hydrocarbons, 230 grams of triacetin and 260 grams of reformed aromatic hydrocarbon oil into the naphtha, and pass through the variable speed circulation gear pump Stir at a slow speed until uniform; 2) Pour 4,500 grams of mineral oil into another mixing reaction vessel, pour 260 grams of catalyst into the mineral oil, through the cutting action of the high-speed pump, and then pass through the catalyst converter. Oil-soluble refinement and stabilization treatment; 3) Pour the solution in mixing reaction vessel 2 into vessel 1, add 1,800 grams of PI-208 and 200 gram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com