Electronic paper laser cutting process

A cutting method and laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of electronic paper abnormalities, easy to have bright spots in electronic paper, and reduce the quality of materials, so as to improve the quality rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

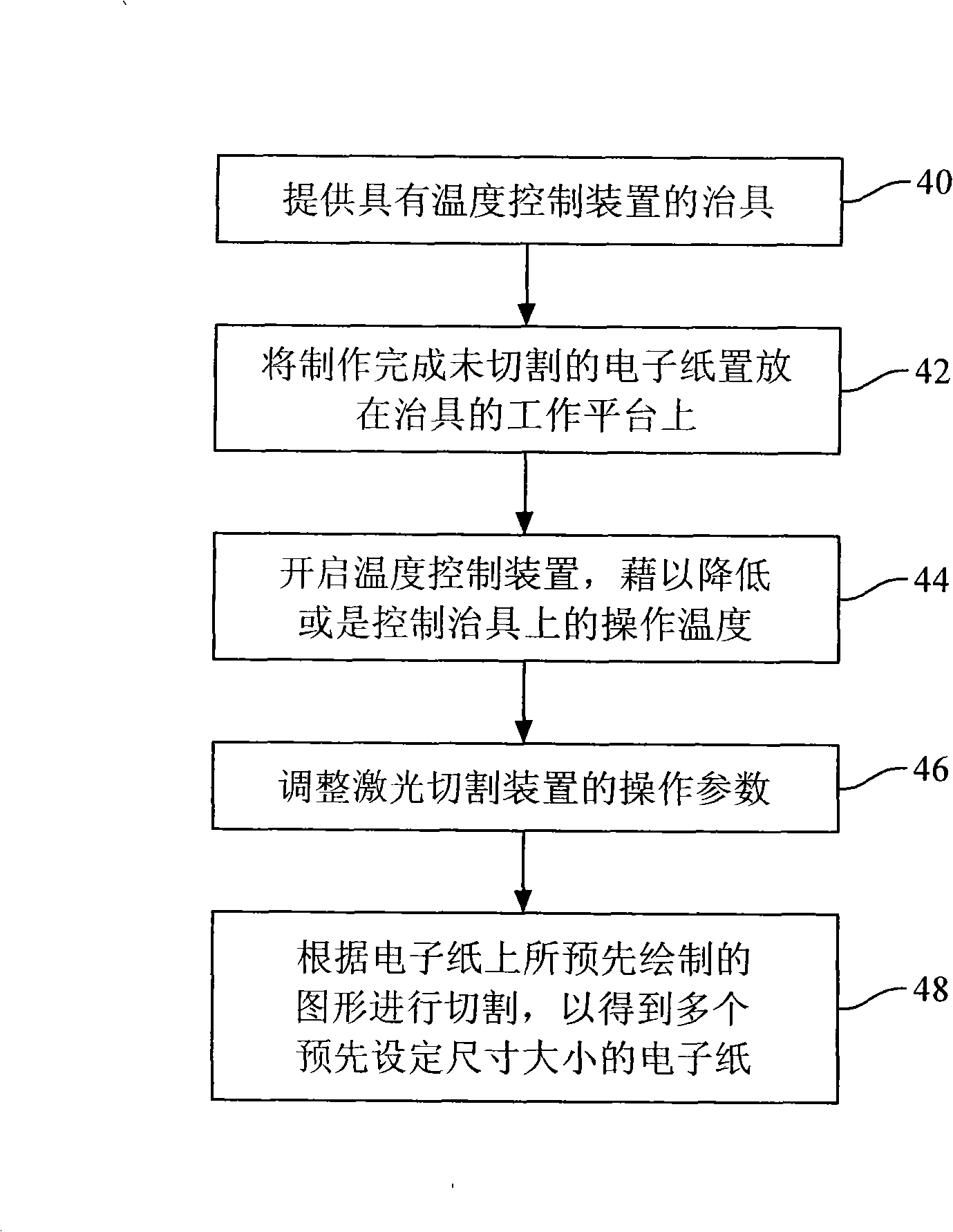

[0027] The invention discloses a laser cutting method for electronic paper, aiming at increasing the yield and quality of electronic paper after cutting and reducing the process cost by laser cutting and matching with a cutting jig with a cooling device.

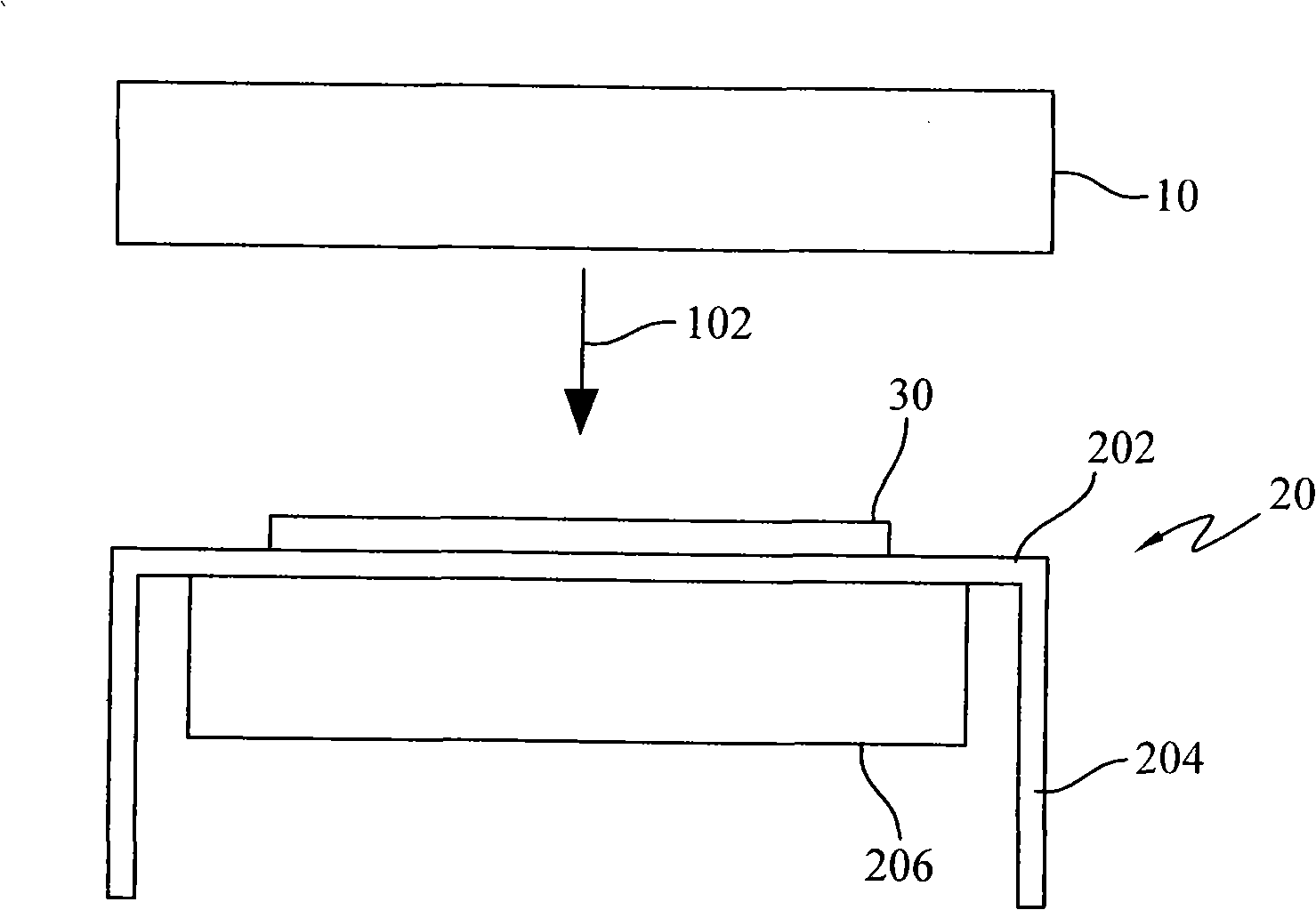

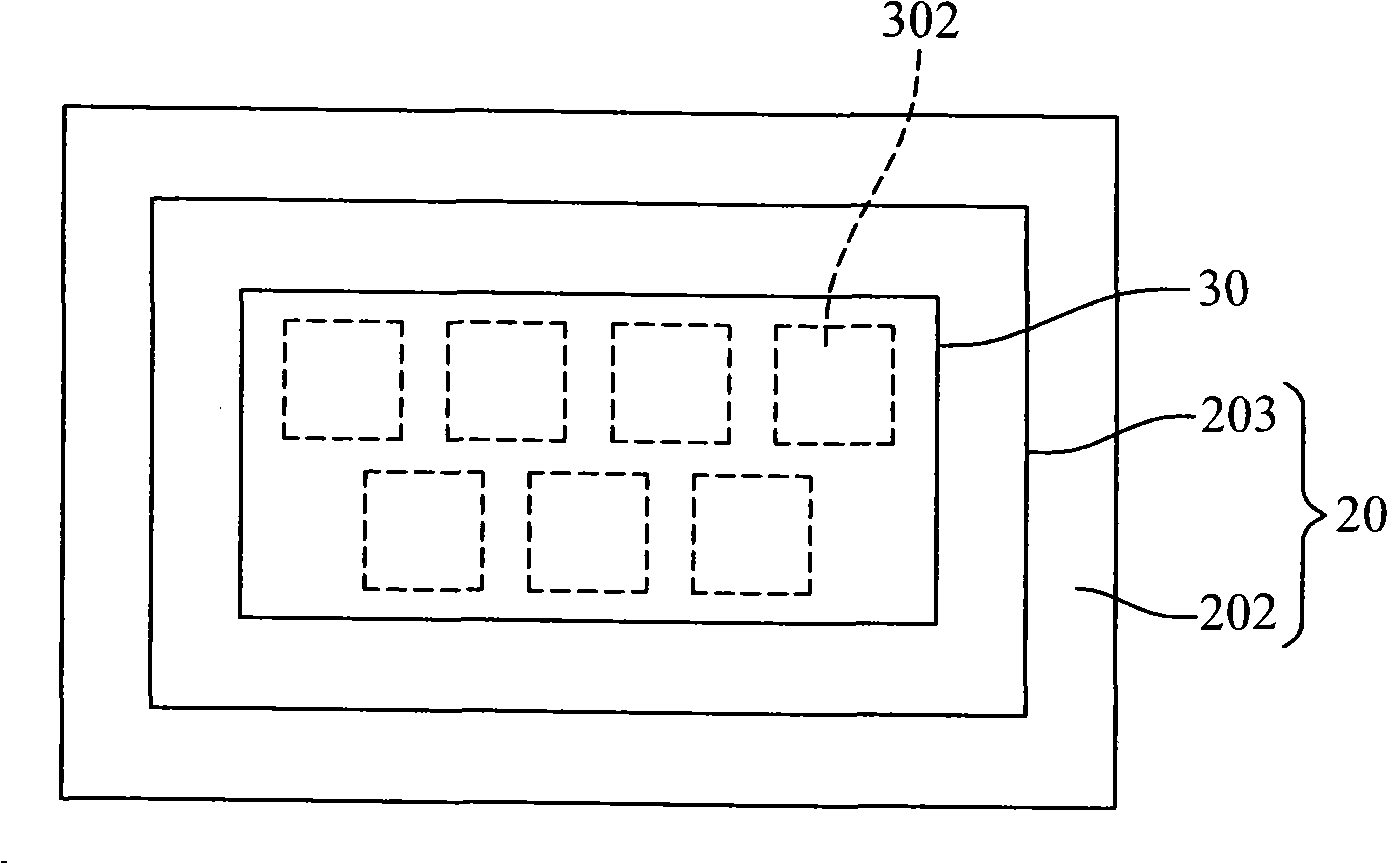

[0028] Figure 1 to Figure 2 It is a schematic diagram of the device according to the electronic paper laser cutting method disclosed in the present invention. image 3 It is a flow chart of the steps of the electronic paper laser cutting method disclosed in the present invention.

[0029] First, please refer to figure 1 , which represents a schematic diagram of the device of the electronic paper laser cutting method disclosed in the present invention. The mark 10 is a laser cutting device. Here, the laser cutting device 10 is a commonly used laser cutting device, which can be applied to the cutting process of electronic paper without special improvement or design. Here, it is worth mentioning that if a reflective device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com