Expanded bed adsorption medium with sulfhydryl ethylpyridine and sulfone group as ligand separation antibody and preparation method

A mercaptoethyl pyridine, adsorption medium technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of not emphasizing thiophilic effect and low antibody selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

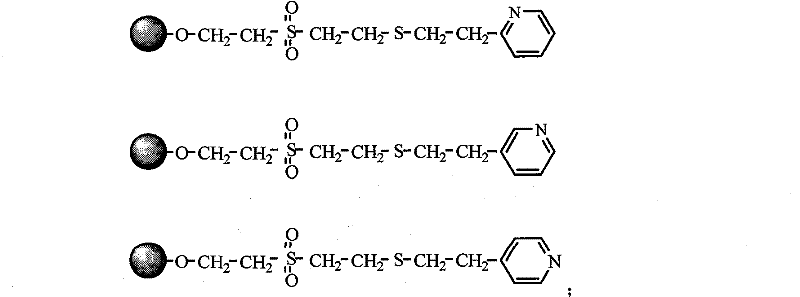

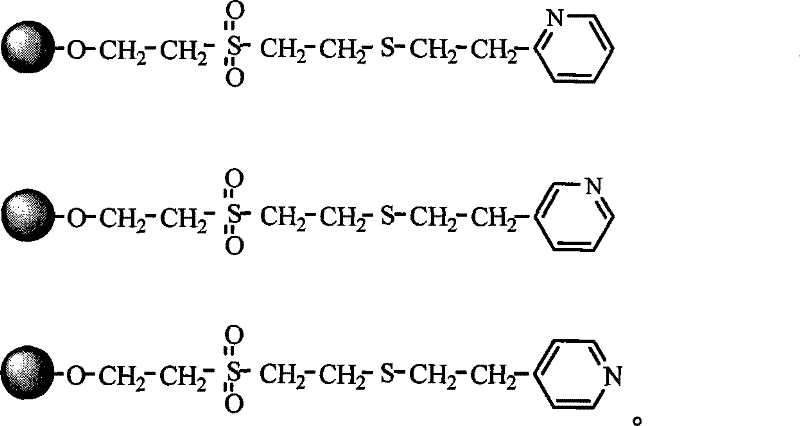

Embodiment 1

[0015] Stir 50g of cellulose viscose and 40g of tungsten carbide powder in a 500ml round-bottomed flask at 300rpm, add 300g of pump oil, rotate at 700rpm, inversely suspend and regenerate to make balls, wash with boiling water and deionized water for 3 to 5 times, Screen cellulose / inorganic weighting agent composite microspheres with a particle size of 50-250 μm as the matrix; 10ml of drained composite microspheres, 3.6ml of divinyl sulfone, 9ml of 0.25M pH12 sodium carbonate buffer and 1.5ml of bismuth Methyl sulfoxide was added into the Erlenmeyer flask, activated in a shaker at 180 rpm at 25°C for 4 hours, the mixed solution was removed by suction filtration, washed with deionized water, and sucked dry. Add 4-mercaptoethylpyridine with 3 times the molar amount of double bonds and 10ml of 0.5M sodium hydroxide solution containing 25mg / ml ammonium persulfate, perform coupling reaction in a shaker at 180rpm at 60°C for 8 hours, and remove the mixed solution by suction filtratio...

Embodiment 2

[0017] Stir 50g of cellulose viscose and 40g of tungsten carbide powder in a 500ml round-bottomed flask at 300rpm, add 300g of pump oil, rotate at 700rpm, inversely suspend and regenerate to make balls, wash with boiling water and deionized water for 3 to 5 times, Screen cellulose / inorganic weighting agent composite microspheres with a particle size of 50-250 μm as the matrix; 10ml of drained composite microspheres, 0.9ml of divinyl sulfone, 9ml of 0.2M pH12 sodium carbonate buffer and 1.5ml of bismuth Methyl sulfoxide was added into the Erlenmeyer flask, activated in a shaker at 180 rpm at 25°C for 4 hours, the mixed solution was removed by suction filtration, washed with deionized water, and sucked dry. Add 4-mercaptoethylpyridine with 3 times the molar amount of double bonds and 10ml of 0.8M sodium hydroxide solution containing 25mg / ml ammonium persulfate, perform coupling reaction in a shaker at 180rpm at 60°C for 8 hours, and remove the mixed solution by suction filtration...

Embodiment 3

[0019] Stir 50g of cellulose viscose and 80g of tungsten carbide powder in a 500ml round-bottomed flask at 300rpm, add 310g of pump oil, rotate at 800rpm, inversely suspend and thermally regenerate to make balls, wash with boiling water and deionized water for 3 to 5 times, Screen cellulose / inorganic weighting agent composite microspheres with a particle size of 50-250 μm as the matrix; 10ml of drained composite microspheres, 1.8ml of divinyl sulfone, 9ml of 0.5M pH12 sodium carbonate buffer and 1.5ml of di Methyl sulfoxide was added into the Erlenmeyer flask, activated in a shaker at 180 rpm at 25°C for 4 hours, the mixed solution was removed by suction filtration, washed with deionized water, and sucked dry. Add 4-mercaptoethylpyridine with 3 times the molar amount of double bonds and 10ml of 0.3M sodium hydroxide solution containing 25mg / ml ammonium persulfate, perform coupling reaction in a shaker at 180rpm at 60°C for 8 hours, and remove the mixed solution by suction filtr...

PUM

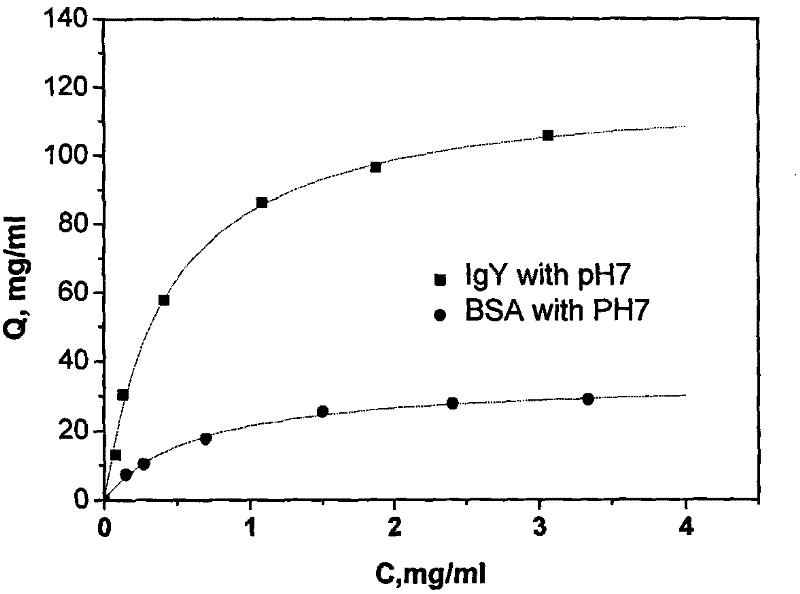

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com