Production chain and preparation technique of aloe extract

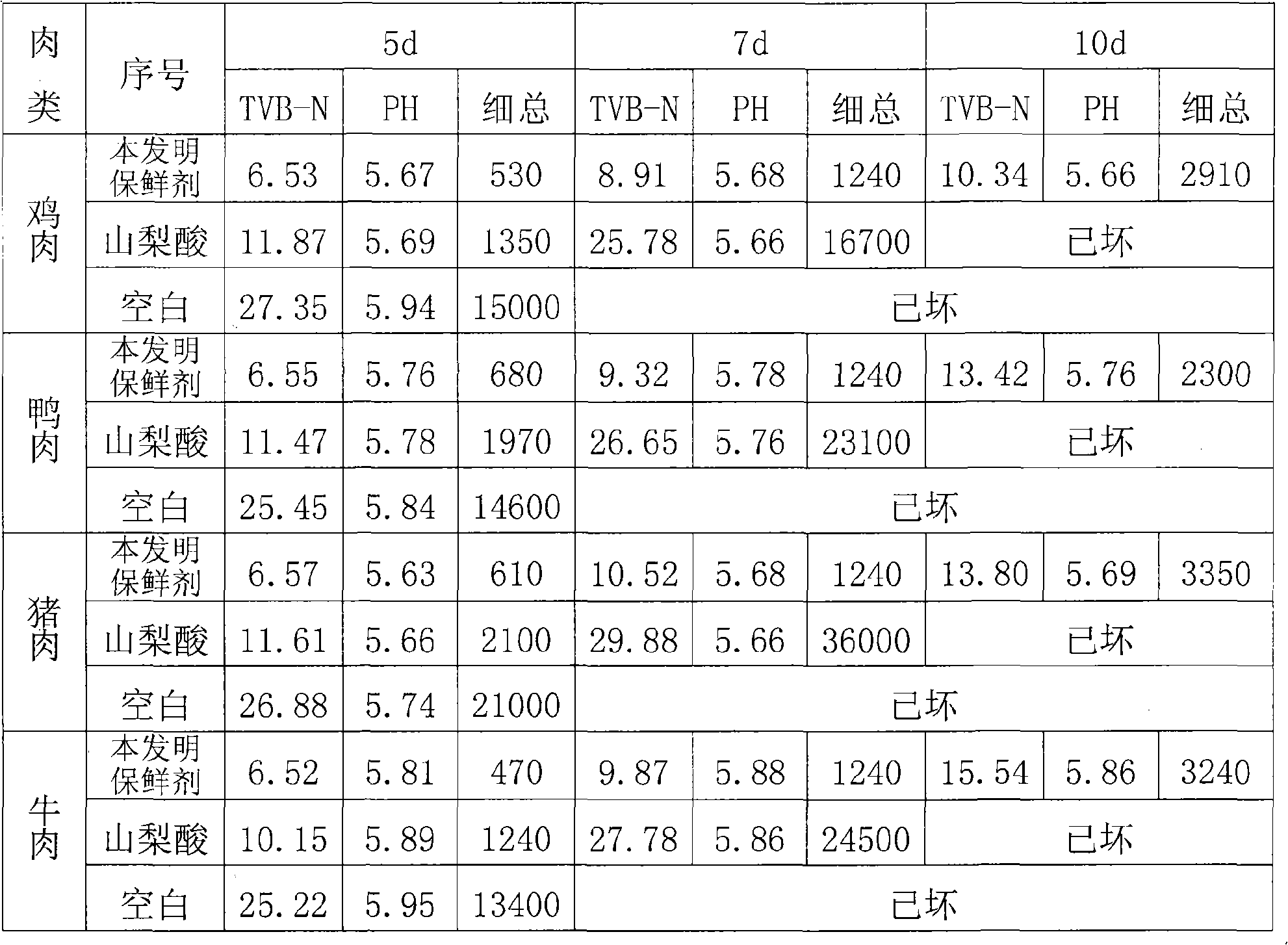

An aloe vera extract and production line technology, which is applied in the direction of preserving meat/fish with chemicals, can solve the problems of meat spoilage, high preservation cost, and strong pertinence, and achieve the promotion of plant resources, reduction of preservation cost, and great economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment one: the preparation of antistaling agent 1

[0019] (1) Take by weighing 4.5Kg of fresh aloe and 1.2Kg of fresh turmeric respectively, put into the universal pulverizer after washing and pulverize to 50 orders.

[0020] (2) The pulverized material is transported to a multi-functional extraction tank, add 57Kg of water, adjust the pressure of the extraction tank to 0.2MPa, and the temperature to 30-40°C. After extraction for 2 hours, let it stand for 24 hours.

[0021] (3) Pump the upper layer extract in the extraction tank into the storage tank, make it pass through the multi-layer screen from top to bottom in order to obtain the filtrate.

[0022] (4) Pump the filtrate into a vacuum concentration tank, concentrate at 4°C, vacuum degree of 0.07Mpa, and steam pressure of 0.20MPa for 0.5 hours to obtain extract.

[0023] (5) The extract is dried by a vacuum spray dryer to obtain 2.21Kg powder.

[0024] (6) Add 133g of salt and 221mL of absolute ethanol to th...

Embodiment 2

[0025] Embodiment two: the preparation of antistaling agent 2

[0026] (1) Weigh 4.0K of fresh aloe and 1.0Kg of fresh turmeric, wash them and put them into a universal grinder to grind them to 50 mesh.

[0027] (2) The pulverized material is transported to a multifunctional extraction tank, add 50Kg of water, adjust the pressure of the extraction tank to 0.2MPa, and the temperature to 30-40°C. After extraction for 2 hours, let it stand for 24 hours.

[0028] (3) Pump the upper layer extract in the extraction tank into the storage tank, make it pass through the multi-layer screen from top to bottom in order to obtain the filtrate.

[0029] (4) Pump the filtrate into a vacuum concentration tank, concentrate at 4°C, vacuum degree of 0.07Mpa, and steam pressure of 0.20MPa for 0.5 hours to obtain extract.

[0030] (5) The extract is dried by a vacuum spray dryer to obtain 1.91Kg powder.

[0031] (6) Add 115g of salt and 191mL of absolute ethanol to the powder, and add sterile wa...

Embodiment 3

[0032] Embodiment three: the preparation of antistaling agent 3

[0033] (1) Weigh 5.0K of fresh aloe and 1.5Kg of fresh turmeric respectively, wash and put into a universal grinder to grind to 50 mesh.

[0034] (2) The pulverized material is transported to a multi-functional extraction tank, 55Kg of water is added, the pressure of the extraction tank is adjusted to 2MPa, and the temperature is 30-40°C. After extraction for 2 hours, stand still for 24 hours.

[0035] (3) Pump the upper layer extract in the extraction tank into the storage tank, make it pass through the multi-layer screen from top to bottom in order to obtain the filtrate.

[0036] (4) Pump the filtrate into a vacuum concentration tank, concentrate at 4°C, vacuum degree of 0.07Mpa, and steam pressure of 0.20MPa for 0.5 hours to obtain extract.

[0037] (5) The extract is dried by a vacuum spray dryer to obtain 2.25Kg powder.

[0038] (6) Add 242g of salt and 225mL of absolute ethanol to the powder, and add st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com