Fluidization-suspension combined combustion boiler

A boiler and fluidization technology, which is applied in the field of fluidized-suspension combined combustion boilers to achieve the effects of cost saving, wide adaptability and operating cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

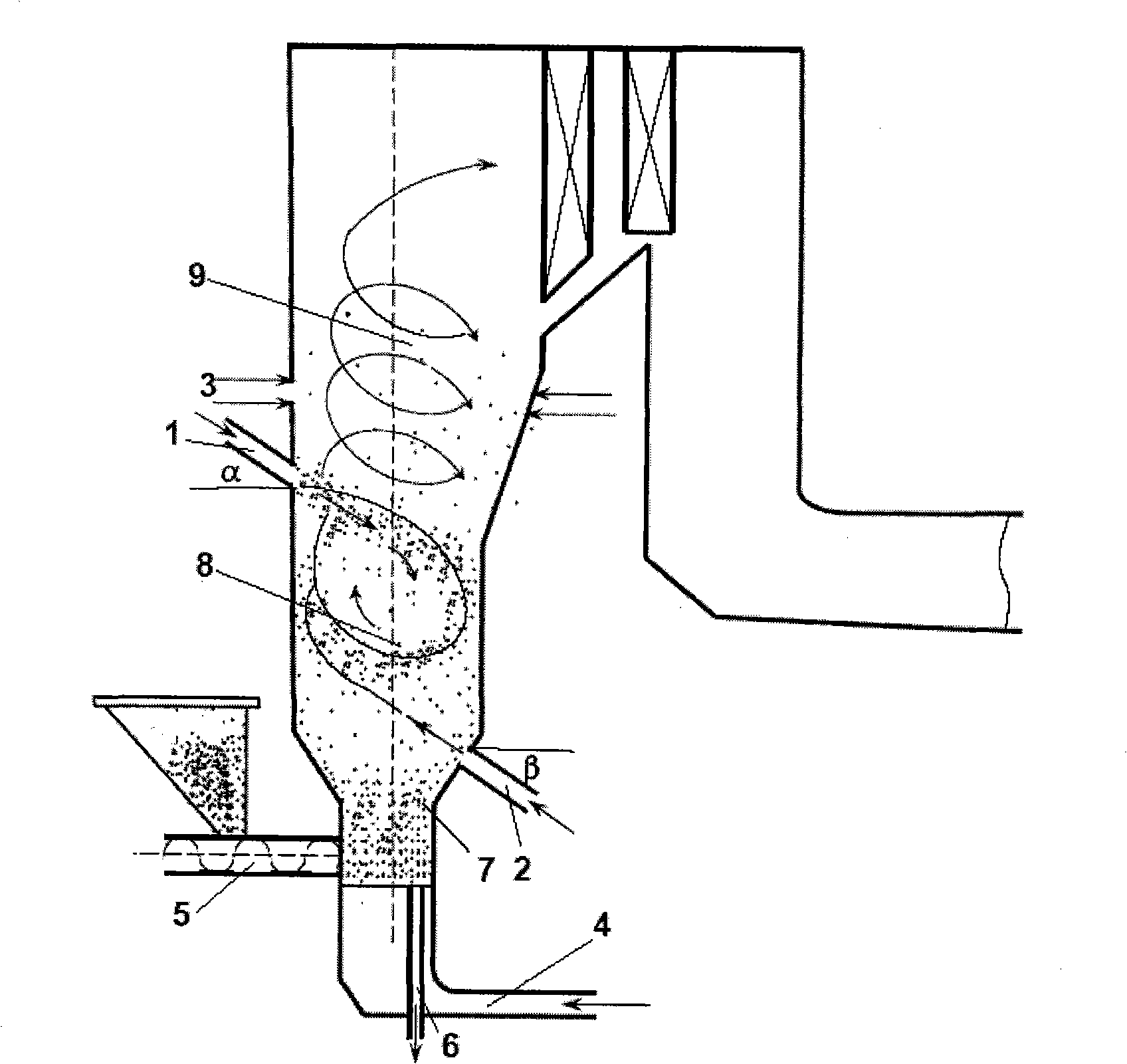

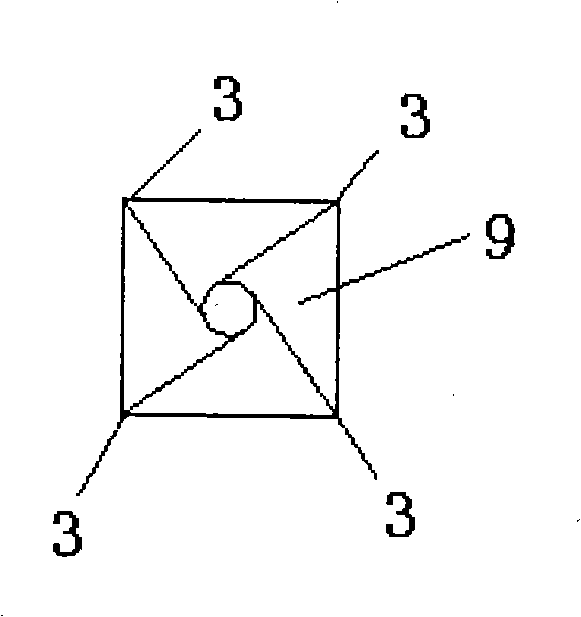

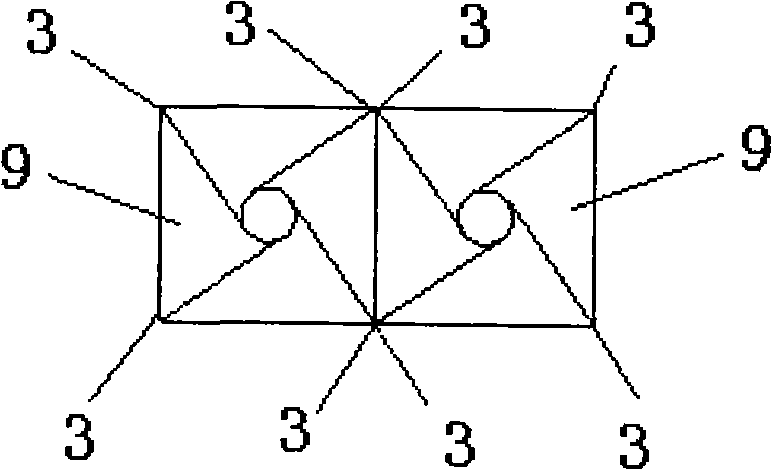

[0028] Such as figure 1 , 2 As shown, a fluidized-suspension combined combustion boiler includes a vertical combustion chamber arranged in a conventional boiler, and the bottom of the combustion chamber is a bubbling fluidized bed combustion zone 7 and is equipped with a feeder 5, a fluidized bed air duct 4 and Fluidized bed slag outlet 6; the lower part of the combustion chamber (ie above the bubbling bed) is a low-temperature reducing main combustion zone 8, and the upper part of the combustion chamber is a high-temperature oxidative burnout zone 9. The bubbling fluidized bed combustion zone 7 at the bottom of the combustion chamber is a conventional bubbling bed structure: a non-directional cylindrical hood is used to spread the air, and the entire bed is composed of N (N=1~20, depending on the boiler capacity) Each cot is composed of three cots, each cot can independently adjust the air supply and fuel volume, and is equipped with an equal pressure air chamber. Use 0-10m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com