Polymer film having micropore structure, preparation and application thereof

A polymer film and microporous structure technology, applied in the field of electrochemistry, can solve the problems of complex process, hidden safety hazards, and numerous parameters of the phase inversion method, and achieve good ionic conductivity and mechanical properties, stable product quality, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 1 gram of sodium bicarbonate and 1.25 grams of sodium citrate (nucleating agent) and grind and mix them uniformly with a mortar, then add 0.54 grams of citric acid, grind and mix them uniformly with a mortar to obtain a composite foaming agent. Get 0.05 grams of composite blowing agent and join 4.5 grams of 1-methyl 2-pyrrolidone solution of polyvinylidene fluoride-hexafluoropropylene copolymer with a concentration of 10%. After stirring for 4 hours, the polymer solution is coated on the glass On chip, evaporate solvent. The obtained solid polymer film was put into a microwave reactor at 120° C. for 3 minutes to foam to obtain a polymer film with a microporous structure.

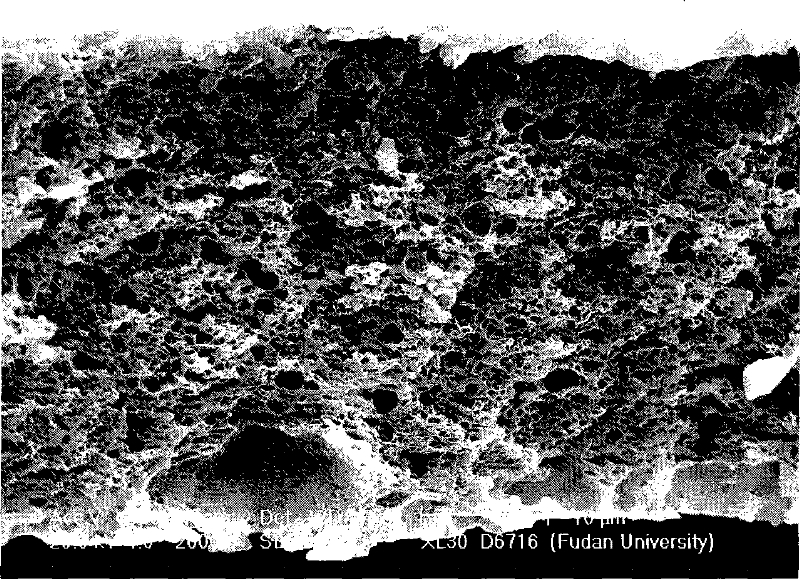

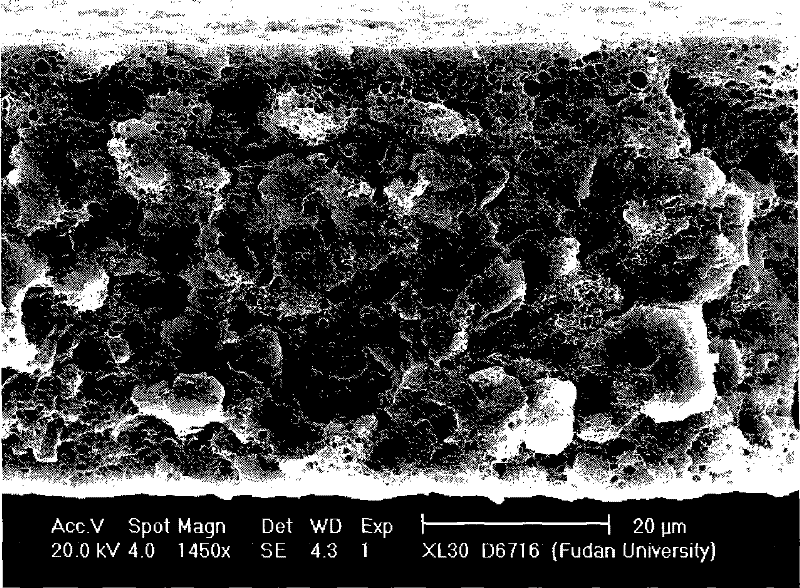

[0023] The scanning electron micrographs of the polymer film with the above-mentioned microporous structure are shown in the attached figure 1 , the obvious microporous structure can be seen from this figure.

Embodiment 2

[0025] Get 1 gram of sodium bicarbonate and 0.54 gram of oxalic acid, grind and mix them uniformly with a mortar to obtain a composite blowing agent. Get 0.10 gram of composite foaming agent and join 4 grams of 10% polyvinylidene fluoride in N, N'-dimethylformamide solution, stir for 1 hour, apply the polymer solution on the glass sheet, and volatilize solvent. The obtained solid polymer film was put into a microwave reactor at 150° C. for 1 minute to foam to obtain a polymer film with a microporous structure.

Embodiment 3

[0027] Get 1 gram of sodium bicarbonate and 1.25 gram of formic acid, grind and mix evenly with a mortar to obtain a composite blowing agent. Get 0.10 gram of composite blowing agent and join 8 grams of concentration and be 10% polyacrylonitrile in the N, N'-dimethylformamide solution, after stirring for 2 hours, the polymer solution is coated on the glass sheet, and the solvent is evaporated . Put the obtained solid polymer film into a microwave reactor at 100° C. for 20 minutes to foam to obtain a polymer film with a microporous structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com