Fiber tube evaporator assembly in refrigerator liner and refrigerator

A wire-tube evaporator and box liner technology, which is used in evaporators/condensers, refrigeration components, coolers, etc., can solve the problems of high temperature of box liner, blackening of smoke, increased scrap rate of box liner, and unfavorable worker operation. , to reduce the scrap rate, facilitate the operation of on-site workers, and facilitate on-site operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

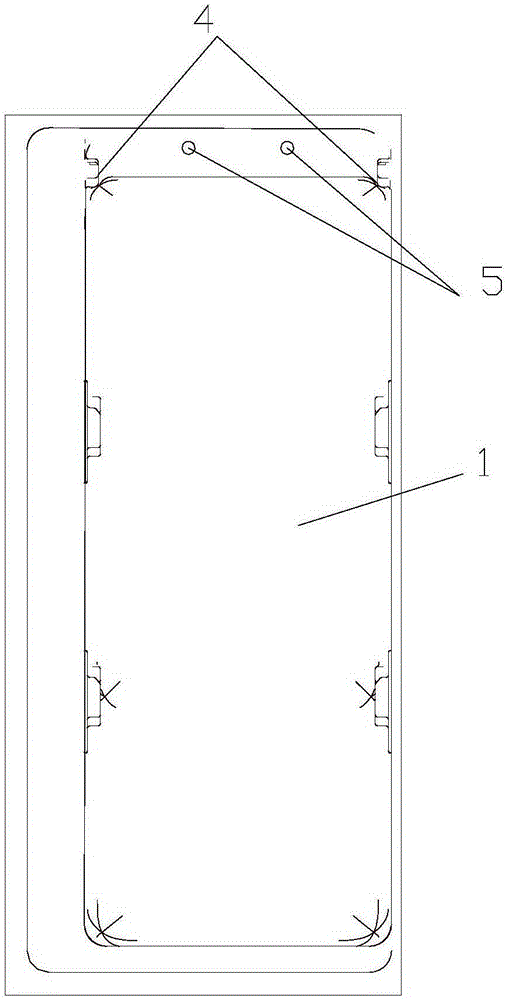

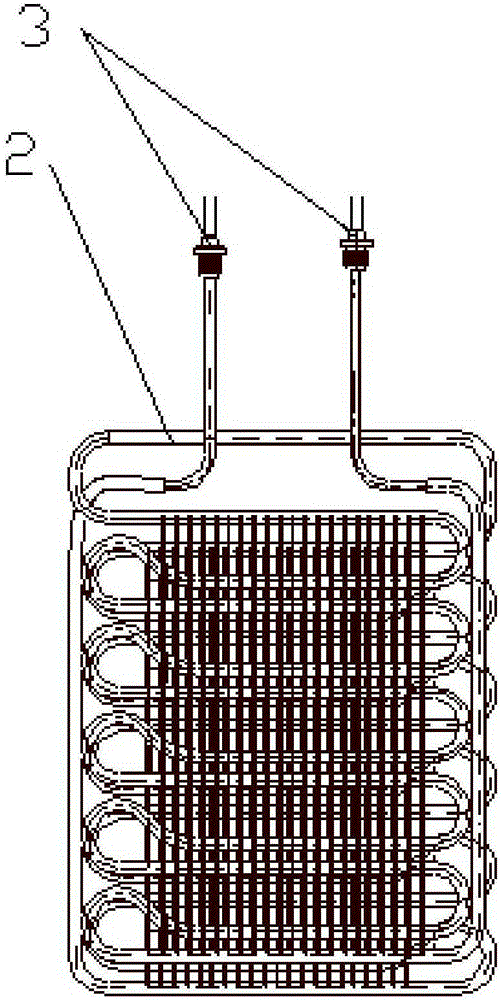

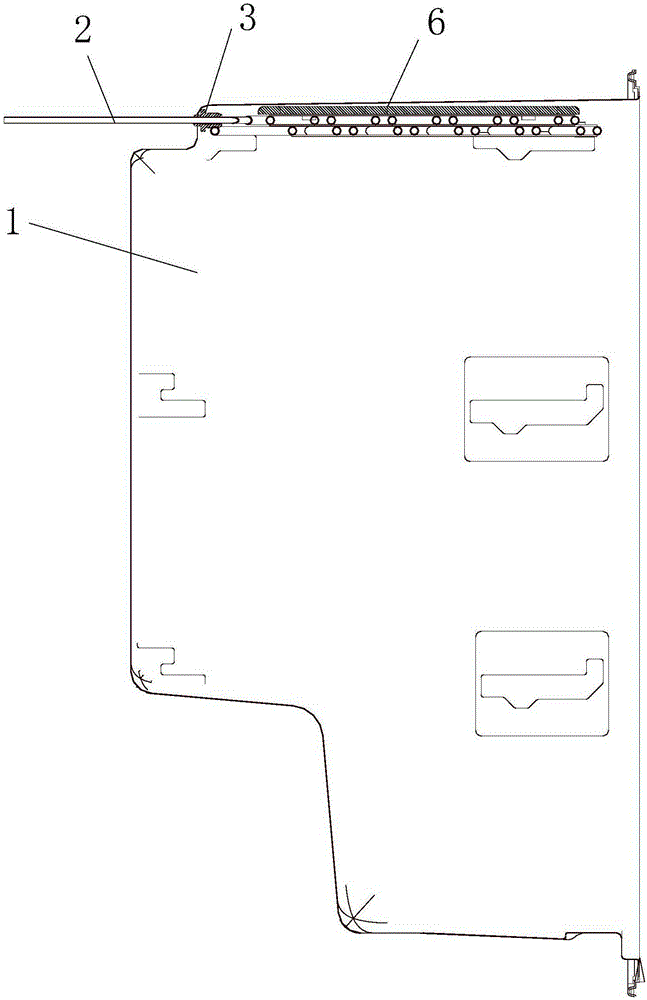

[0031] Such as Figure 1 to Figure 3 As shown, a wire tube evaporator assembly in a box includes a box 1 and a wire tube evaporator 2 located inside the box 1, the inlet and outlet of the wire tube evaporator 2 are located in the wire tube On the same side of the evaporator 2, the tank 1 is provided with circular holes 5 corresponding to the inlet and outlet of the wire tube evaporator 2, and the inlet and outlet of the wire tube evaporator 2 respectively pass through The round hole 5 extends out of the box 1.

[0032] Preferably: the inlet and outlet of the wire tube evaporator 2 are located on the same horizontal plane. It is convenient for production and installation, simplifies the process, and facilitates on-site operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com