Novel dust-collecting and dust-removing flexible conveying system

A conveying system and flexible technology, which is applied in the field of new dust collection and dust removal flexible conveying system, can solve the problems of dust accumulation and solidification, dust leakage of ash hopper, increase of manufacturing cost, etc., to reduce the occupied area, reduce the occupied area, The effect of reducing the number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

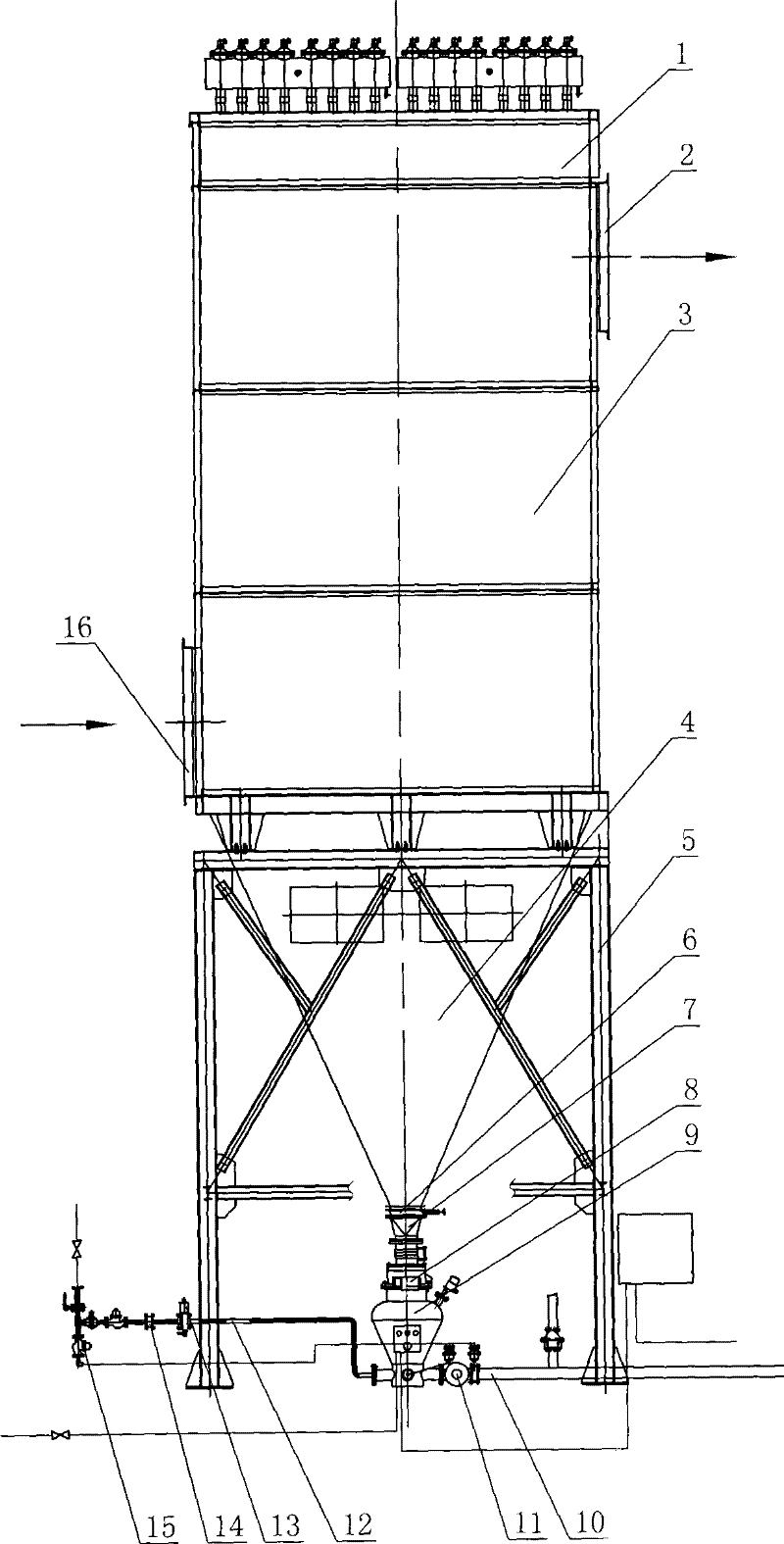

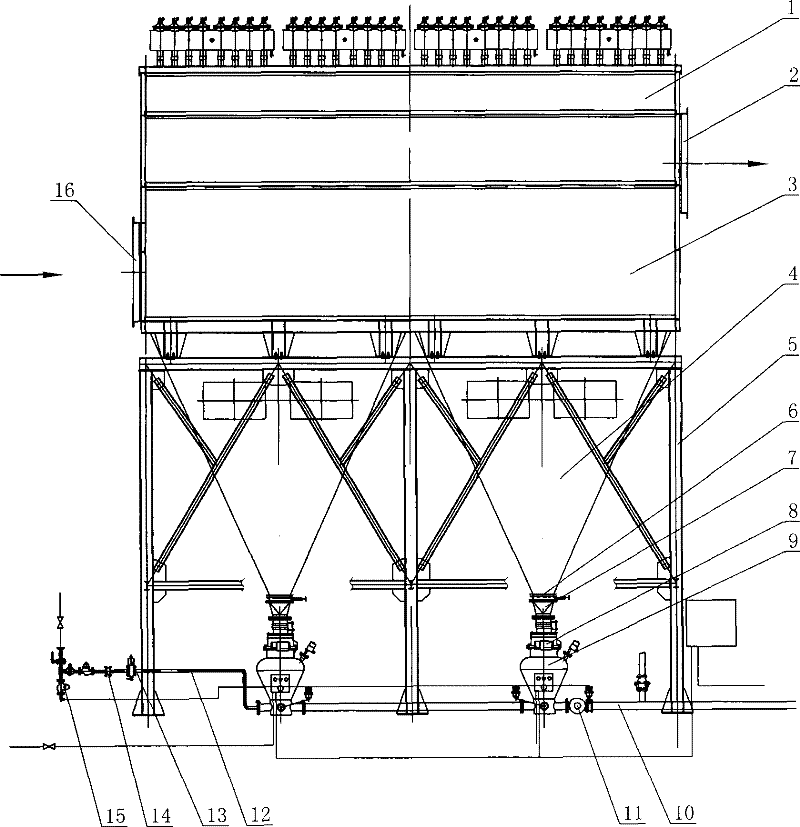

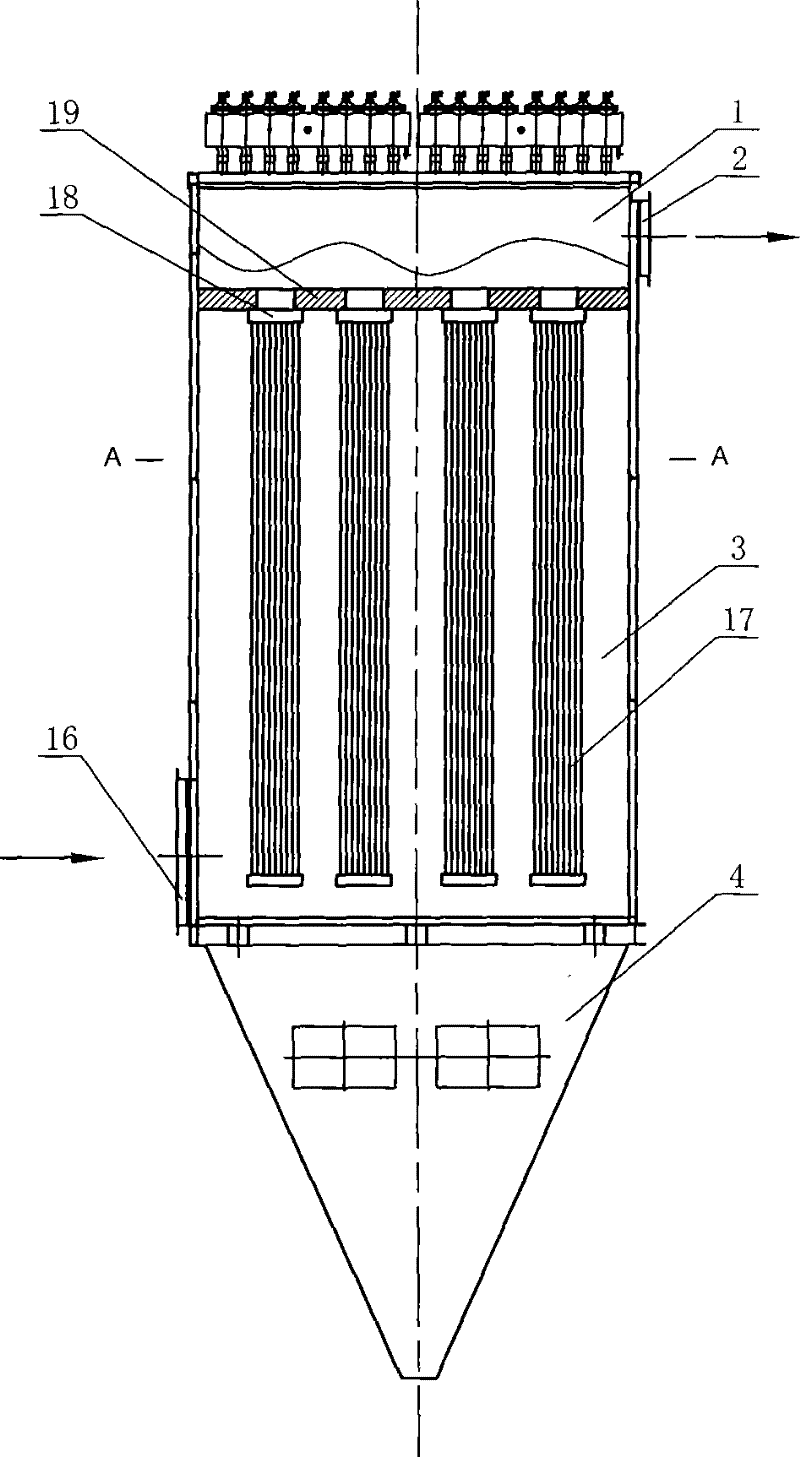

[0039] A new type of flexible conveying system for dust collection and dust removal is composed of a frame 5 and a bag filter, which is installed on the frame. The bag filter is composed of an upper box 1 and a lower box 3. According to different needs, the shape of the bag filter can be designed as a rectangle or a circle. A porous plate 19 is fixed horizontally on the inner side of the lower box of the bag filter, and a dust bag 17 is vertically and evenly distributed at the lower part of the porous plate. The quantity can be adjusted as needed. The bottom of the lower box is installed with an ash hopper 4 that communicates with the lower box. A dust inlet 16 is formed on one side of the lower box, and the dust inlet communicates with the lower box. A clean air outlet 2 is formed on the other side of the upper box body opposite to the dust air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com