Spraying rotating brush dust collecting device

A technology of spraying and rotating brush type and dust removal device, which is applied in the field of boilers, can solve the requirements for the uniformity of filtering wind speed and flue gas flow speed distribution, which is not suitable for high viscosity dust and high humidity flue gas dust removal, and bag filter operation resistance. It is beneficial to particle adhesion, reduce high temperature corrosion and chemical corrosion, and has strong anti-ash blocking ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

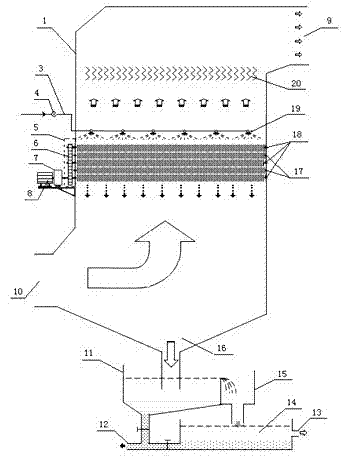

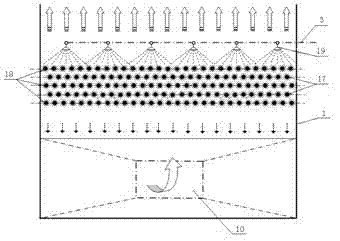

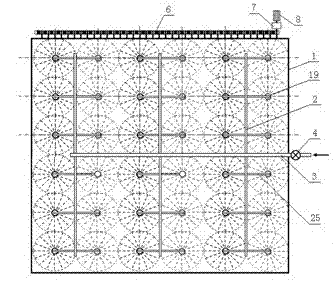

[0022] See Figure 1, Figure 2, image 3 , Figure 4 , the overall structure of the present invention is that the lower part is provided with the tower body of flue gas inlet 10, and the top is provided with flue gas outlet 9, and the tower body comprises a brush filter layer, a spray layer, a mortar pool and a demister 20, and the brush The filter layer is composed of a rotating brush layer 18, a fixed brush layer 17, a transmission mechanism 6, a sealing cover 5, a speed reducer 7 and a drive motor 8. The rotating brush layer 18 and the fixed brush layer 17 are arranged alternately. In order to rotate the brush layer 18, the rotating brush layer 18 and the fixed brush layer 17 are composed of a group of brushes and brush shafts 24, the brushes are wound on the corresponding brush shafts 24, and the transmission mechanism 6 is placed in a sealed Inside the cover 5, both ends are respectively connected with the brush shaft of the rotating brush layer 18 and the output shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com