Cooling device

A heat dissipation device and heat dissipation fin technology, which can be used in cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve problems such as unsatisfactory functions, and achieve the effect of improving heat dissipation performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

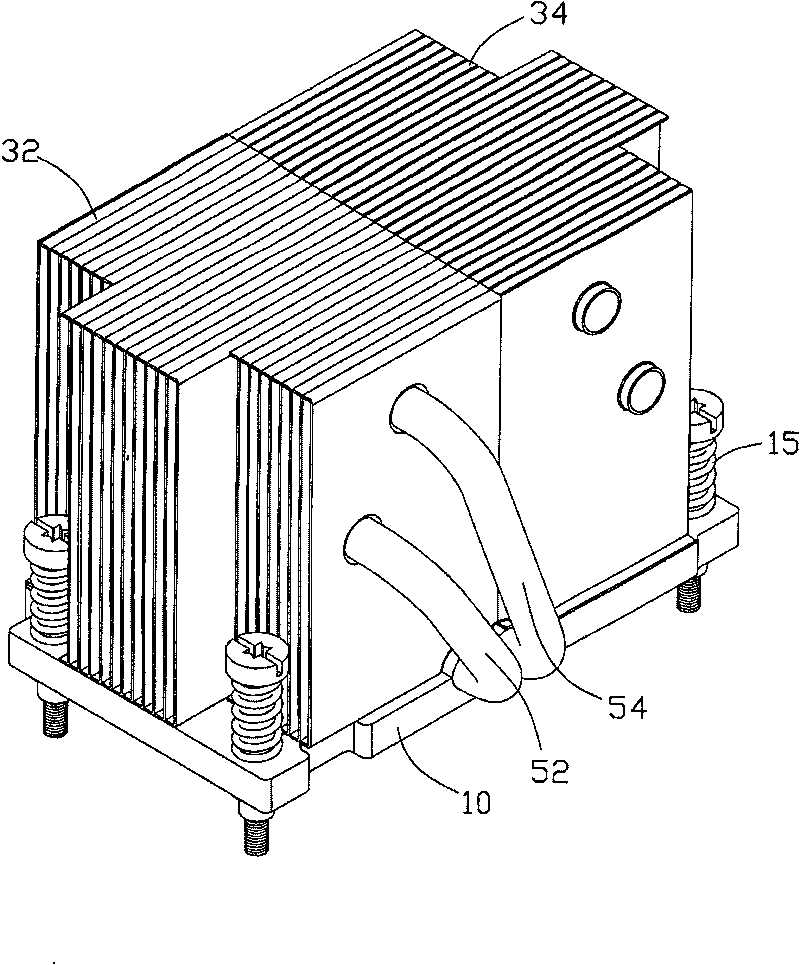

[0011] see figure 1 The heat dissipation device of the present invention includes a base plate 10, a first fin group 32 placed on the base plate 10, a second fin group 34, and two fin groups connecting the base plate 10 and the first and second fin groups 32, 34. Heat pipes 52,54.

[0012] The bottom plate 10 is a roughly rectangular metal plate with good thermal conductivity, such as a copper plate, an aluminum plate, and the like. The lower surface (not shown) of the bottom plate 10 is used to contact the electronic components (not shown) on a circuit board (not shown), and the upper surface of the bottom plate 10 is provided with two parallel adjacent grooves 120 to combine Heat pipes 52,54. Four screws 15 are passed through the four corners of the bottom plate 10 to fix the heat sink on the circuit board where the electronic components are located.

[0013] Two corners of the first cooling fin set 32 close to the screw 15 are cut off to form a receiving space (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com