Method and apparatus for preparing high-intensity cobaltic-cobaltous oxide power

A technology of cobalt tetroxide and high density, applied in cobalt oxide/cobalt hydroxide and other directions, can solve the problems of poor product quality, difficult implementation and large investment, and achieve the effects of high product quality, convenient process system, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution invented is described in detail below.

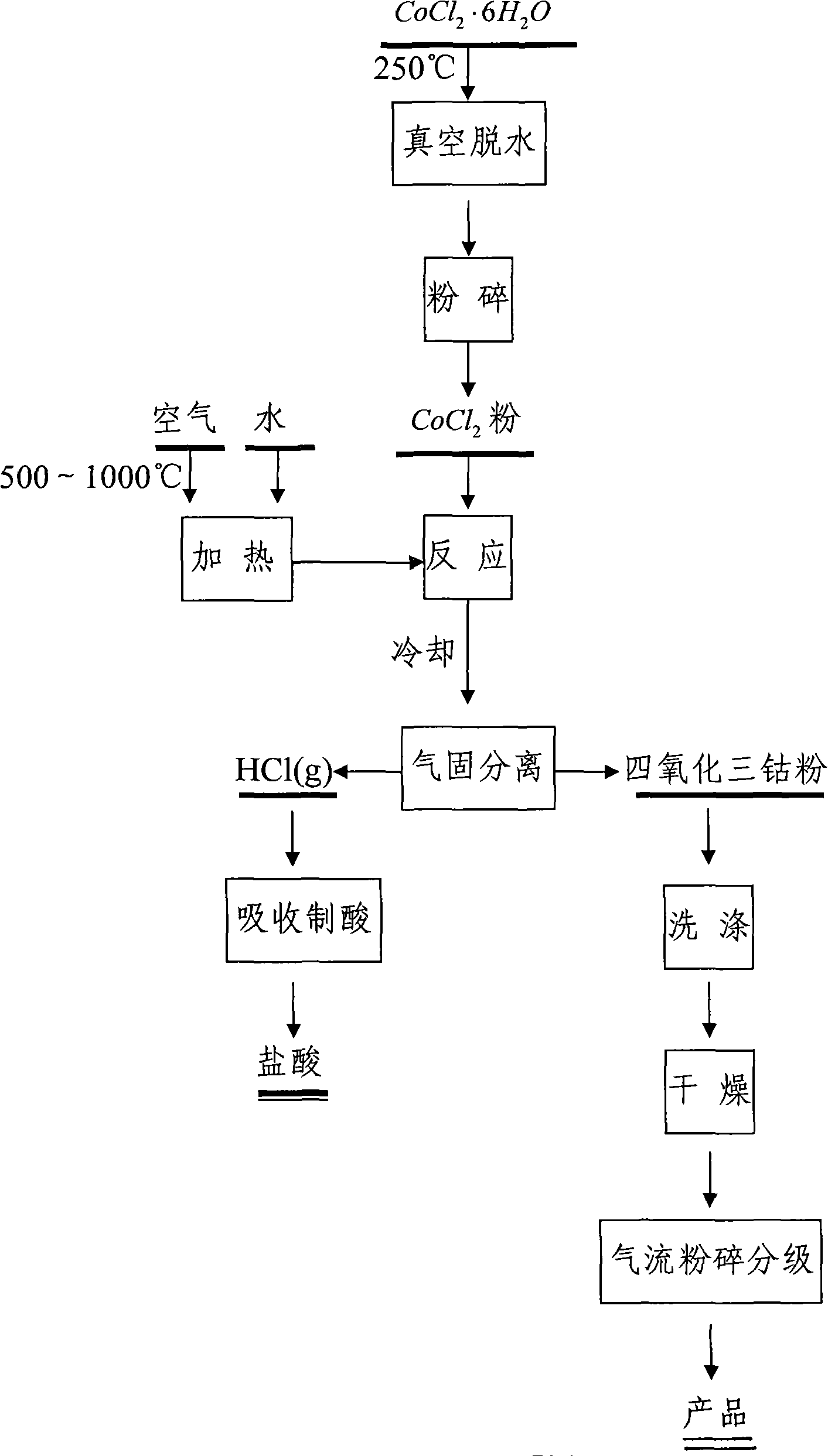

[0015] Such as figure 1 As shown, the CoCl used in the present invention 2 The raw material is battery-grade CoCl 2 ·6H 2 O, it is prepared by pulverizing after heating and vacuum dehydration at a temperature of 250°C, with a particle size of 100-400 mesh. The oxygen content of the reaction gas is 21-50%. Generally, air can be used, or oxygen can be added to the air; the water in the reaction gas is delivered to the atomizer by a metering pump, and the water is sprayed after atomization High-temperature gas flow is added in gasification. Therefore, the moisture content in the high-temperature oxidizing gas is controllable. Generally, it is added at 100-120% of the stoichiometric amount. If it is too high, the exhaust gas dew point will increase, causing the dust collection system to work only at high temperatures. It is difficult to choose the material of the dust collecting bag during operation.

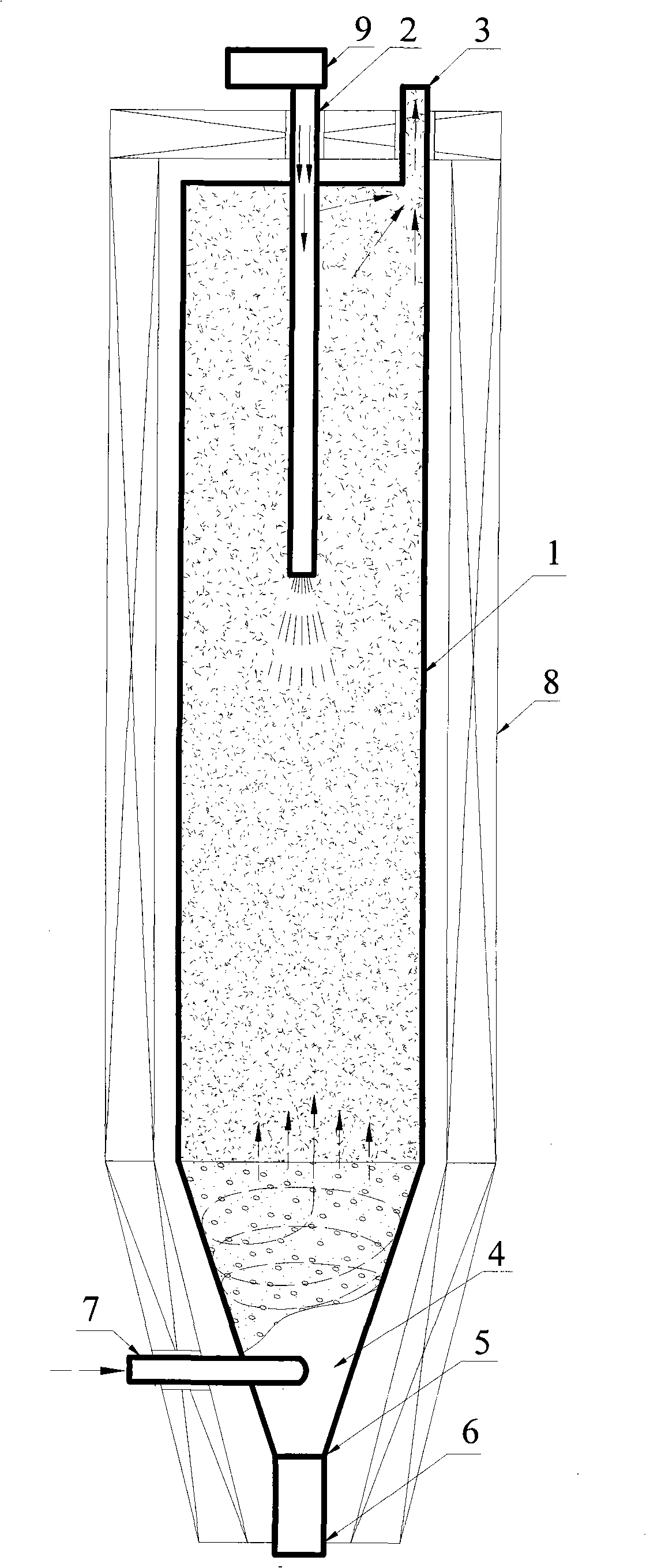

[0016] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com