Absorbing agent for removing and recovering sulfur dioxide from gaseous mixture

A sulfur dioxide and absorbent technology, which is applied in the direction of inorganic chemistry, sulfur compounds, chemical instruments and methods, etc., can solve the problems of waste residue pollution, ammonia escape, ammonia nitrogen pollution, etc., and achieves a small footprint, low operating cost, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

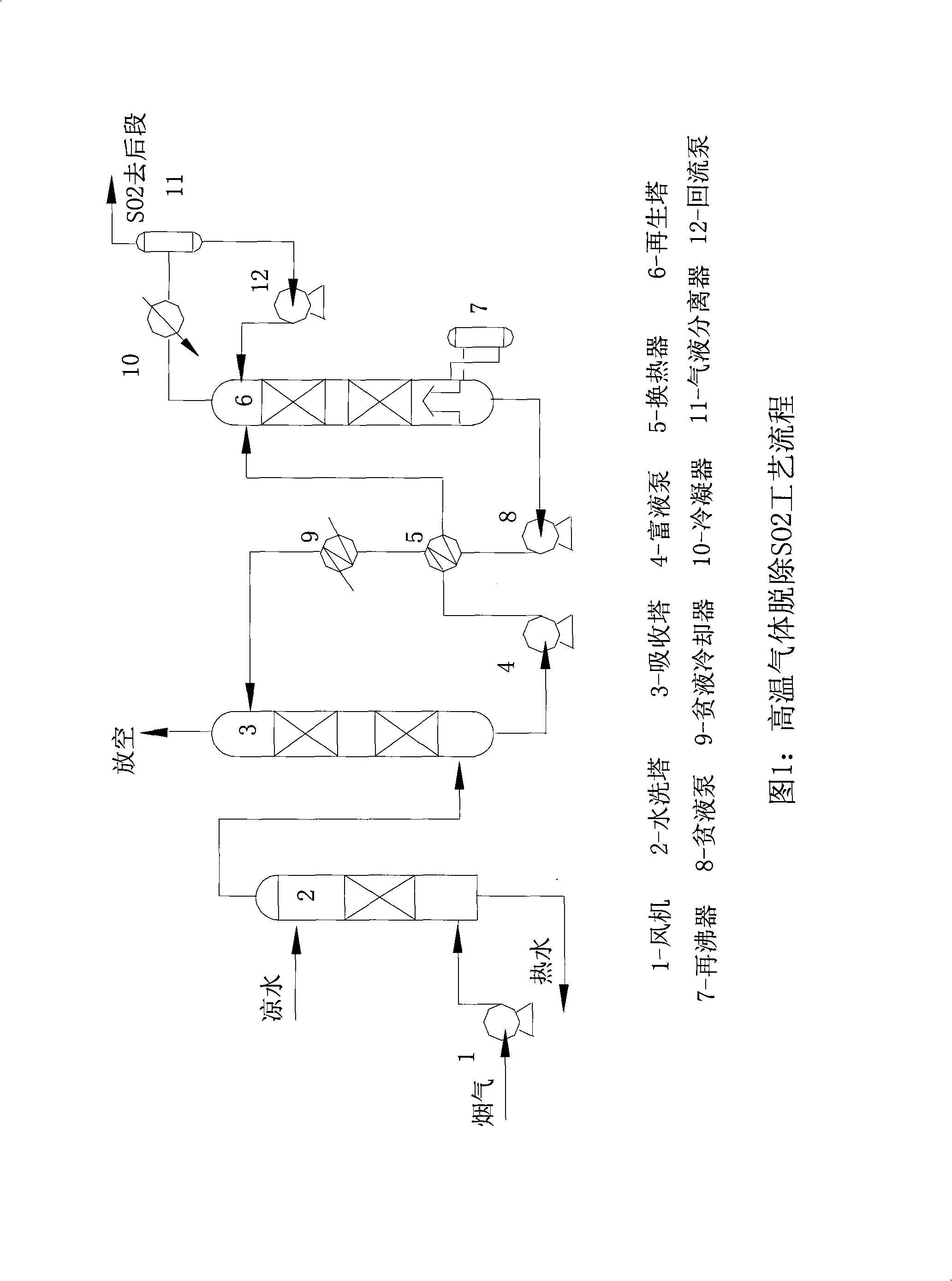

[0020] Sintering flue gas of a large iron and steel company, SO in the gas 2 The content is 3500~11000mg / Nm 3 , the temperature is 130°C, the pressure is -5Pa, and the process flow shown in Figure 1 is adopted:

[0021] After the flue gas is pressurized by the fan (1), it enters the water washing tower (2) to remove dust and cool down, and then sends it to the absorption tower (3). 2 Absorbed by the absorbent, the outlet gas is emptied. Absorb SO 2 The final rich liquid enters the poor-rich liquid heat exchanger (5) from the bottom of the tower through the pump (4), and enters the upper part of the regeneration tower (6) after recovering heat. Desorbed SO 2 After being cooled by condenser (10) together with water vapor, separate and remove moisture, obtain the product SO of purity 99.5% 2 Gas, sent to the next section for use. The condensed water separated from the regeneration gas is sent to the top of the regeneration tower by the pump (12). The rich liquid enters fro...

Embodiment 2

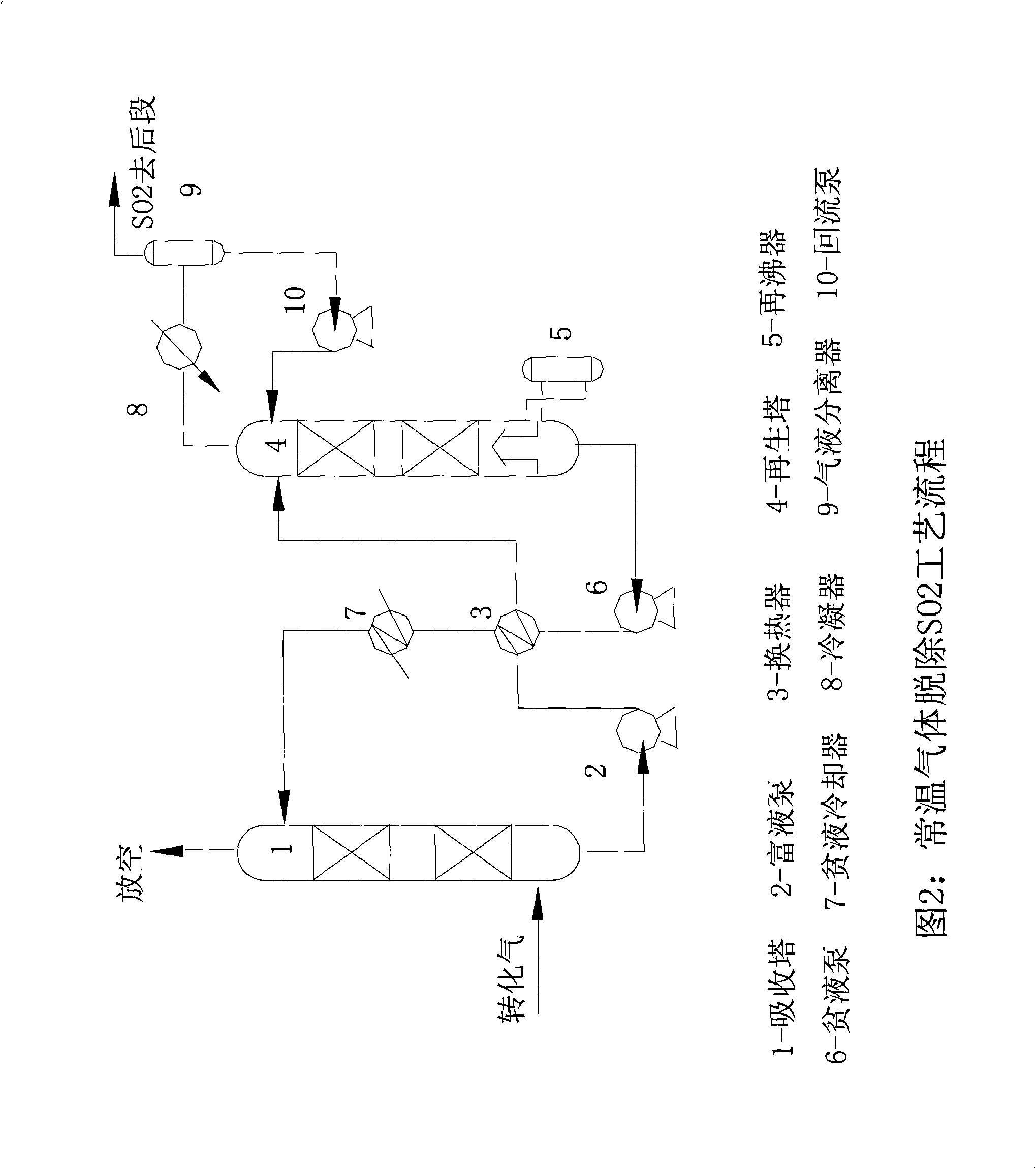

[0026] SO in conversion gas of a sulfuric acid plant 2 The content is 12-14%, the temperature is normal temperature, and the pressure is 4kPa. The process flow shown in Figure 2 is adopted:

[0027] The reformed gas first enters the absorption tower (1), and the SO in the flue gas 2 Absorbed by the absorbent, the outlet gas is emptied. Absorb SO 2 The final rich liquid enters the poor-rich liquid heat exchanger (3) from the bottom of the tower through the pump (2), and enters the upper part of the regeneration tower (4) after recovering heat. Desorbed SO 2 After being cooled by condenser (8) together with water vapor, separate and remove moisture, obtain the product SO of purity 99.5% 2 Gas, sent to the next section for use. The condensed water separated from the regeneration gas is sent to the top of the regeneration tower by the pump (10). The rich liquid enters from the upper part of the regeneration tower, and part of the SO is desorbed by stripping 2 , and then int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com