Air backheating type mine gas separation and liquefaction method and apparatus

A gas and heat recovery technology, applied in the field of gas separation and liquefaction, can solve the problem of high energy consumption, and achieve the effects of high energy consumption, simple manufacturing process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

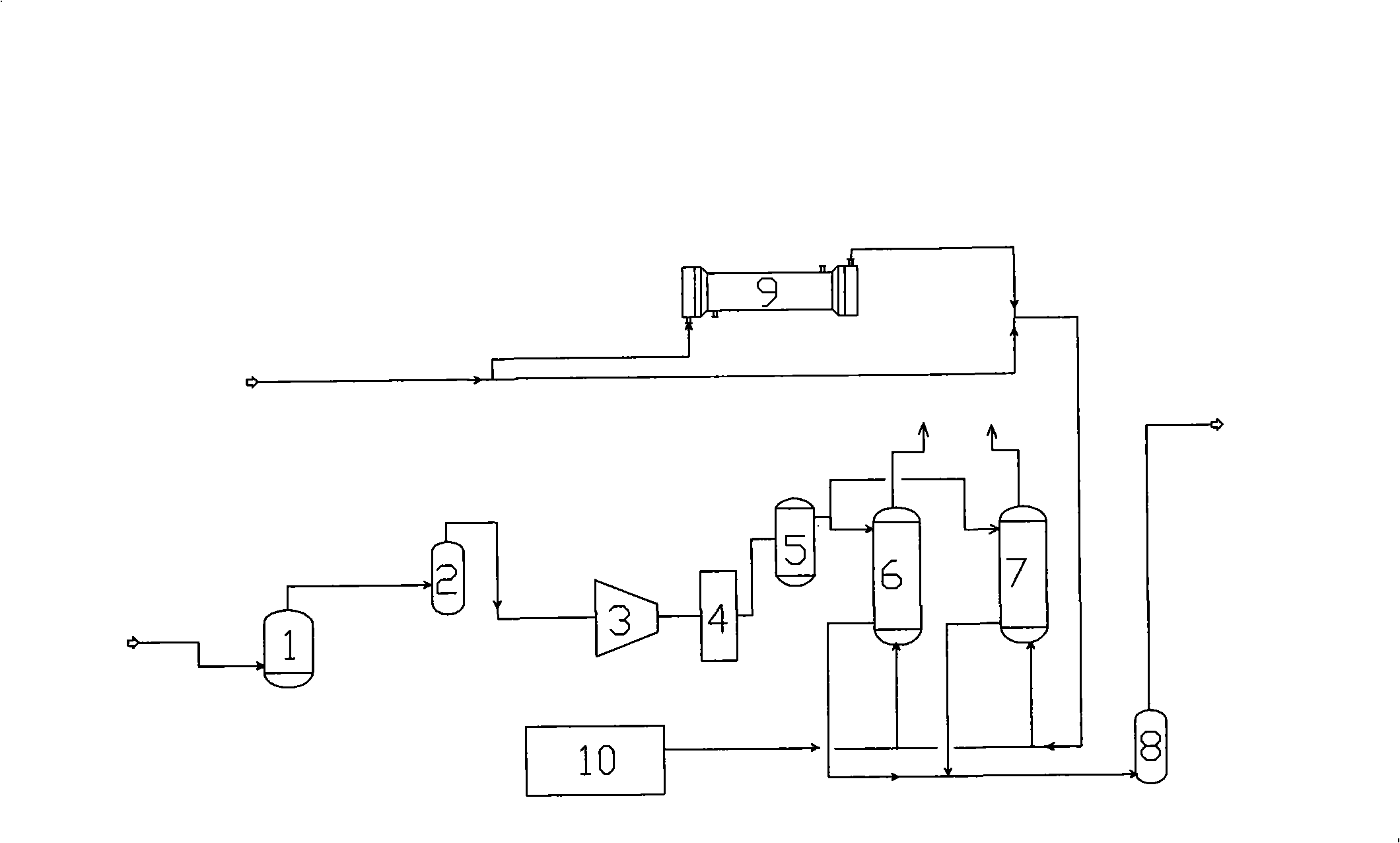

[0041] see figure 1 , is a schematic diagram of the compression purification equipment in Example 1 of the present invention. Including filter 1, gas-liquid separator 2, compressor 3, cooler 4, gas-liquid separator 5, molecular sieve purification equipment group, the molecular sieve purification equipment group includes two molecular sieve dryers 6, 7, when the first one When the molecular sieve dryer 6 is in operation, the second molecular sieve dryer 7 is heated for regeneration, cooled for standby, and switched every 12 hours. The molecular sieve drying equipment is mainly used to remove water and carbon dioxide. There is a filter 8 and a heater 9 behind the molecular sieve equipment group. In addition, there is a pressure swing adsorption nitrogen generator 10 to provide nitrogen for replacing the gas in the purification equipment.

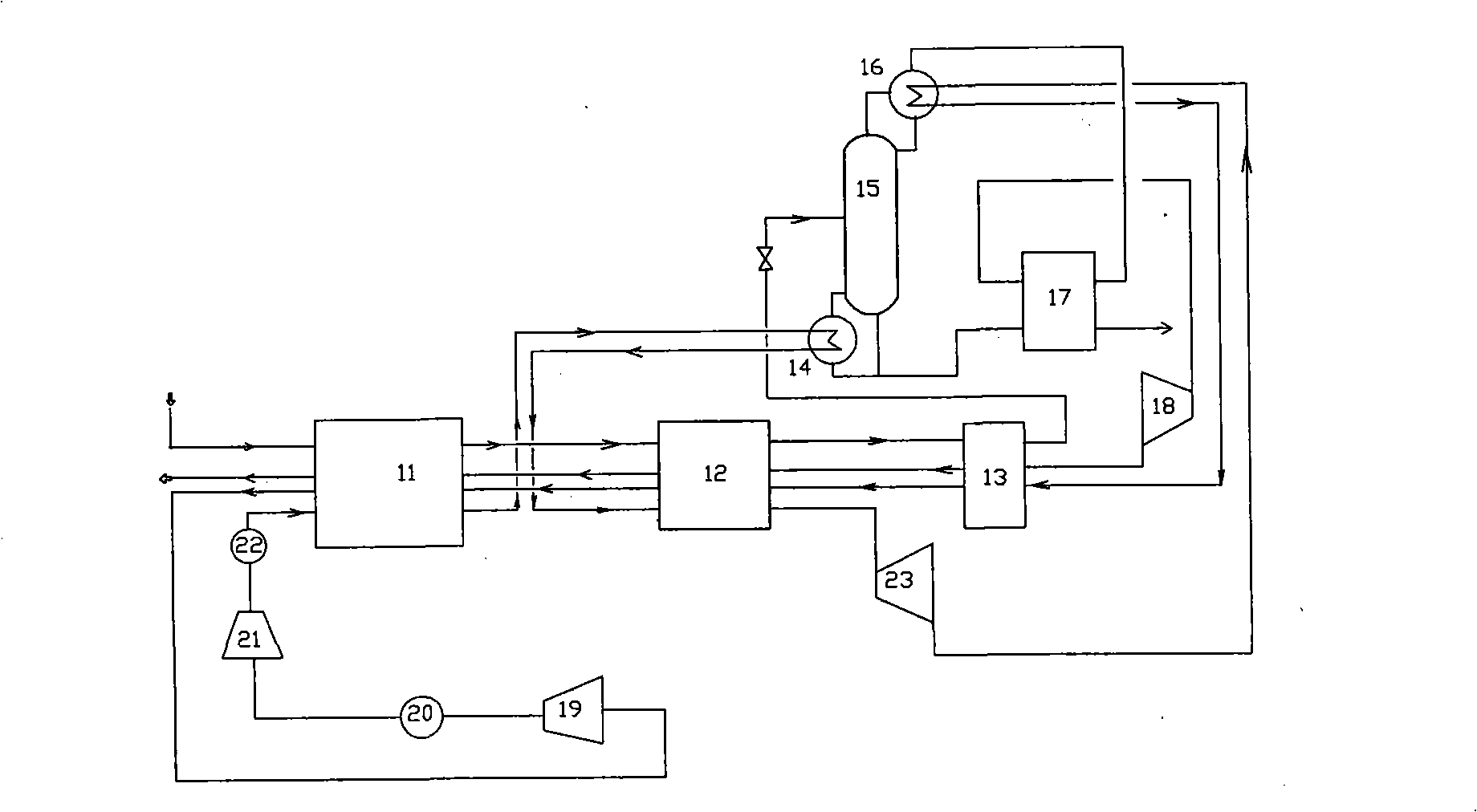

[0042] Figure 4 Shown is the overall process flow diagram of the method for separating and liquefying mine gas using the air recuperatio...

Embodiment 2

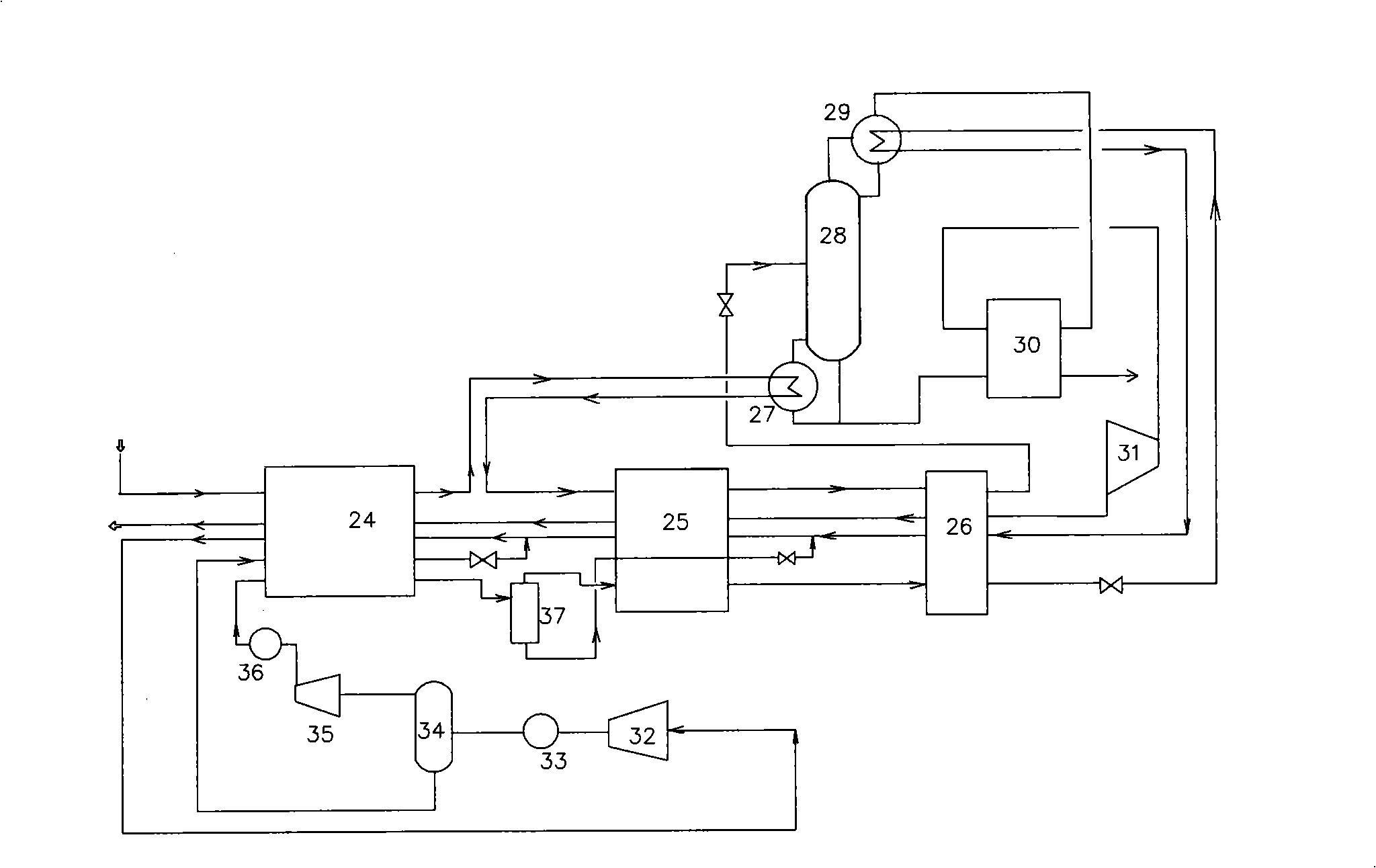

[0064] see image 3 , is a schematic diagram of the refrigeration equipment and the liquefaction separation equipment in Example 2 of the present invention. The heat exchanger and fractionation tower for separating the liquefied part are basically the same as those in Example 1, and the description will not be repeated. The difference is that the feed gas is first cooled to 0°C to -50°C through the heat exchanger 24, and then passes through the evaporator 27 at the bottom of the fractionation tower to provide heat for the evaporator, while the feed gas itself is pre-cooled. Therefore, on the equipment, the heating pipeline of the evaporator 27 of the fractionation tower is connected with the raw material gas pipeline, and then the raw material gas is cooled to -150℃~-180℃ through the heat exchangers 25 and 26, so that most of the mine gas is It is cooled to a liquid and then enters the middle of the fractionation column 28 . Another difference is that the refrigeration syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com