Polyalcohol intercalation calcium aluminum hydrotalcite as concrete additive and preparing method thereof

A technology of concrete admixture and hydrotalcite, applied in polymer intercalated calcium-aluminum hydrotalcite and its preparation, polymer anion intercalated hydrotalcite is used as concrete early strength water reducing agent and its preparation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

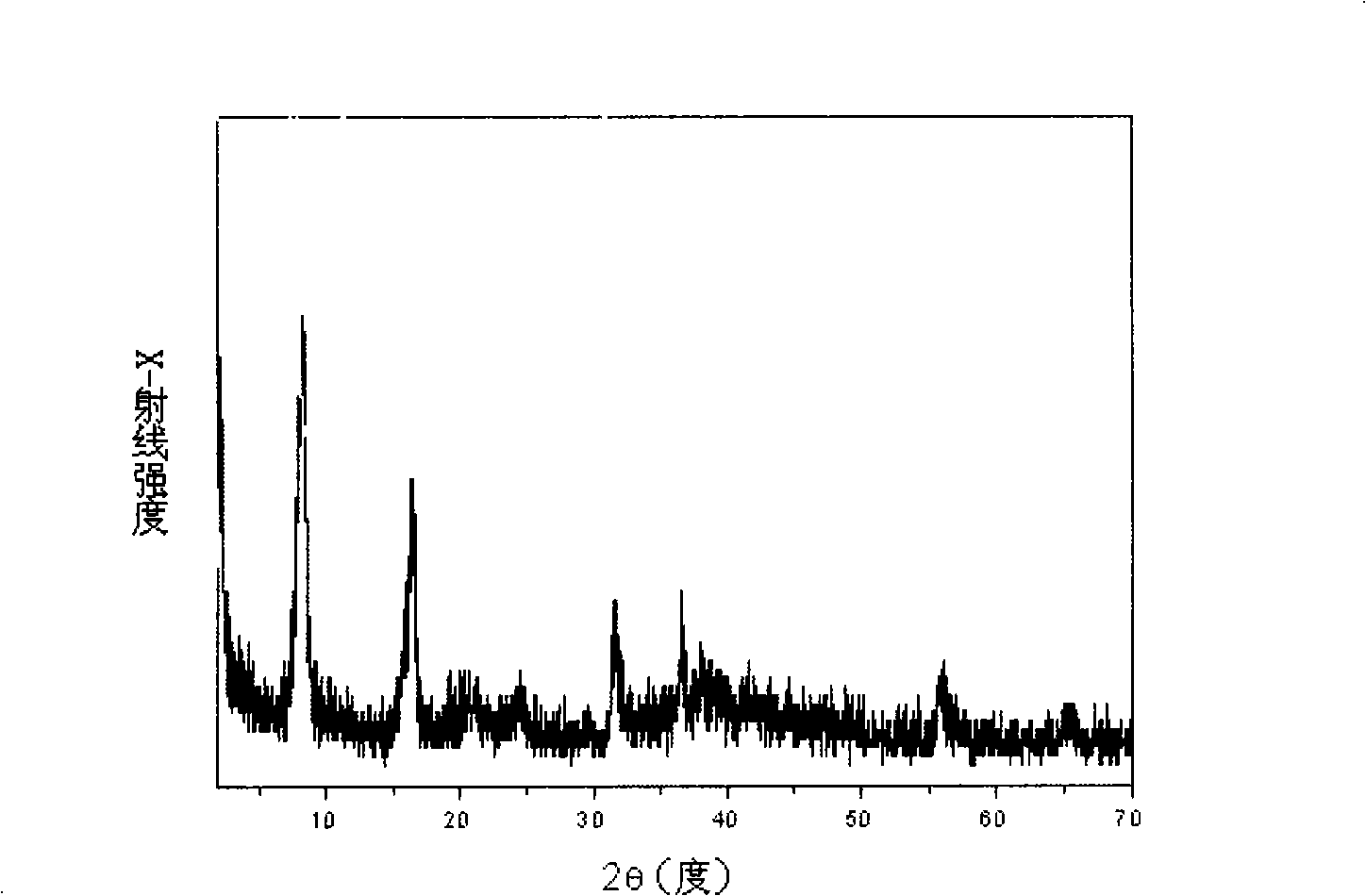

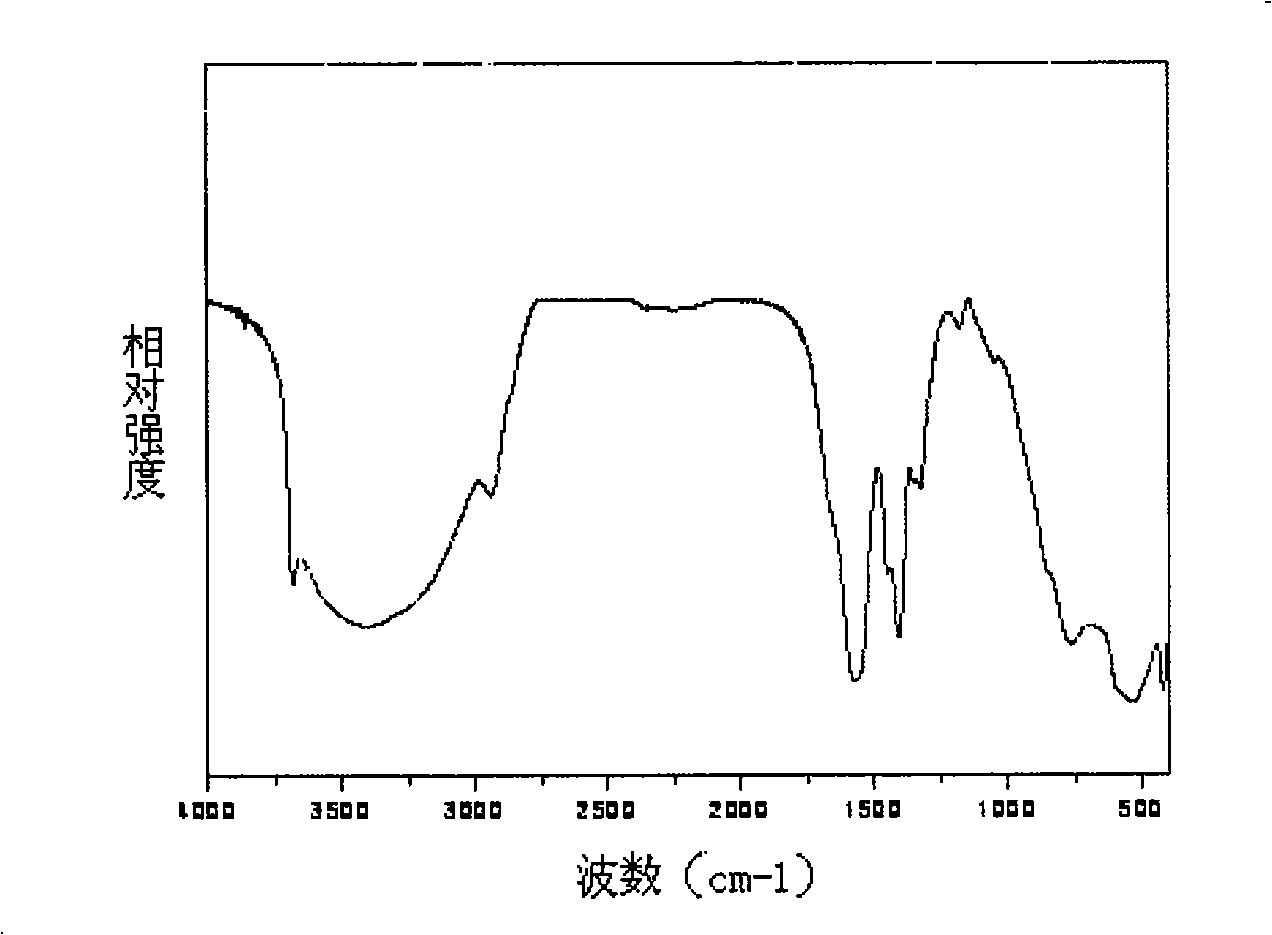

Image

Examples

example 1

[0031] A: Weigh 77.60g CaCl 2 2H 2 O and 63.76g AlCl 3 ·6H 2O was dissolved in 800mL ethanol water solution (the volume ratio of absolute ethanol and deionized water was 1 / 4), stirred evenly, and stood for later use; The volume ratio of water is 1 / 4), stir evenly, and put it aside for later use; add the above two solutions to the crystallizer at the same time, adjust the slit width between the rotor and the stator to be 2mm, the working voltage is 140V, and the rotor speed is 5000rpm , stirring for 1 to 2 minutes, adding the obtained mixed slurry into a three-necked flask, heating and stirring, keeping the temperature of the mixed slurry in the bottle at 70° C. for reflux crystallization for 24 hours, and obtaining calcium aluminum hydrotalcite precursor;

[0032] B: The product prepared in step A is fully washed with deionized water, so that the pH value of the supernatant is 7. Remove the supernatant, take 2.66g of CaAl-Cl slurry, put it in a petri dish, and dry it in an...

example 2

[0037] A: Same as example 1;

[0038] B: Same as example 1;

[0039] C: Same as example 1;

[0040] D: Weigh 6.913g of the hydrotalcite-like slurry obtained in step B, and then weigh 10g of 40% by mass sodium polyacrylate solution to prepare a 10% saline solution. Mix the slurry with the salt solution, and stir well to make the system uniform; use the NaOH solution prepared in step C to adjust the pH of the system to 11. The system was crystallized in an oven at 70°C for 24 hours to obtain calcium-aluminum hydrotalcite intercalation products;

[0041] E: Same as Example 1;

example 3

[0043] A: Weigh 9.70g CaCl 2 2H 2 O and 7.97g AlCl 3 ·6H 2 O was dissolved in 100mL deionized water, stirred evenly, and left to stand for later use; then 9.24g NaOH was weighed and dissolved in 100ml of deionized water, stirred evenly, and left for later use; the above two solutions were added to the crystallizer at the same time, and the rotor and The width of the slit between the stators is 2mm, the working voltage is 140V, the rotor speed is 5000rpm, stir for 1 to 2 minutes, add the obtained mixed slurry into a 500ml three-necked flask, heat and stir, and keep the temperature of the mixed slurry in the bottle at 70°C. After 24h, calcium aluminum hydrotalcite precursor is obtained;

[0044] B: half of the product prepared in step A is placed in a 250ml beaker;

[0045] C: Weigh 6.875g of sodium polyacrylate (M=3000~5000, calculated by M=4000, the content is greater than 96%, calculated by 96%), dissolve it in about 25ml of deionized water, dissolve all the sodium polyac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com