Water boiler

A water boiler and sensor technology, applied to water boiling appliances and other directions, can solve problems such as errors, large temperature control errors, and it is difficult to eliminate thousands of boiling water, so as to ensure health and safety, facilitate temperature and time, or eliminate adverse effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

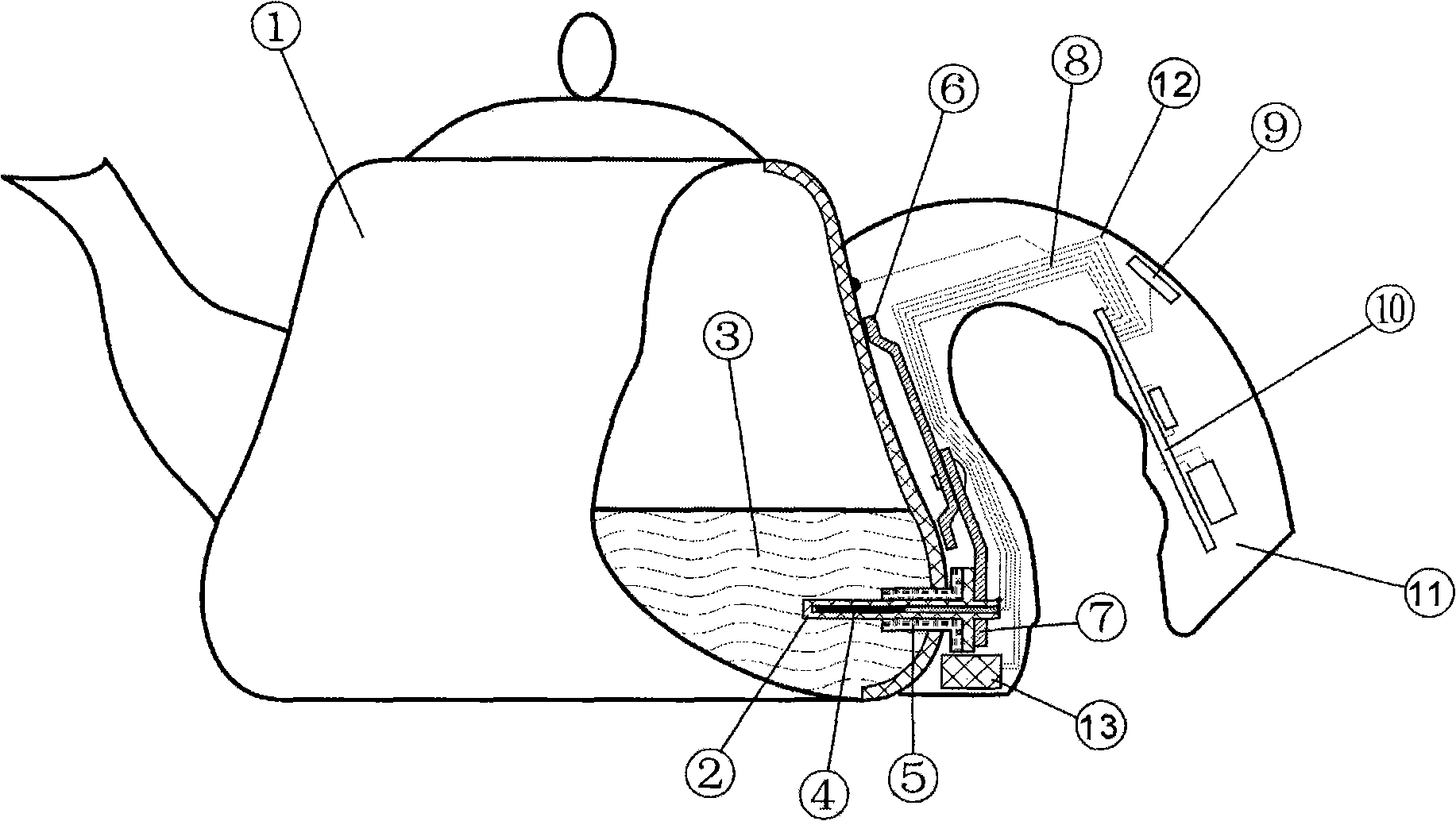

[0024] figure 1 The utility model relates to a stainless steel kettle which is specially used on an electromagnetic cooker and adopts an electromagnetic induction power supply. The temperature sensor 4 is insulated and packaged in the stainless steel housing 2 of the sensor, and extends into the stainless steel kettle body 1. The shortest distance between the stainless steel housing 2 of the sensor and the bottom of the inner cavity of the kettle body 1 is 2 cm to reserve a dry margin of the water 3. There is a liner 5 between the stainless steel shell 2 of the sensor and the via hole on the kettle body 1 for positioning, insulation and leakage prevention. The material of the liner 5 is ion exchange resin. The handle fixing bracket 6 is welded on the kettle body 1, on which the plastic pressing sheet 7 is connected by screws, so that the plastic pressing sheet 7 is pressed against the liner pipe 5. Handle 11 is installed on the handle fixed support 6, and temperature display...

Embodiment 2

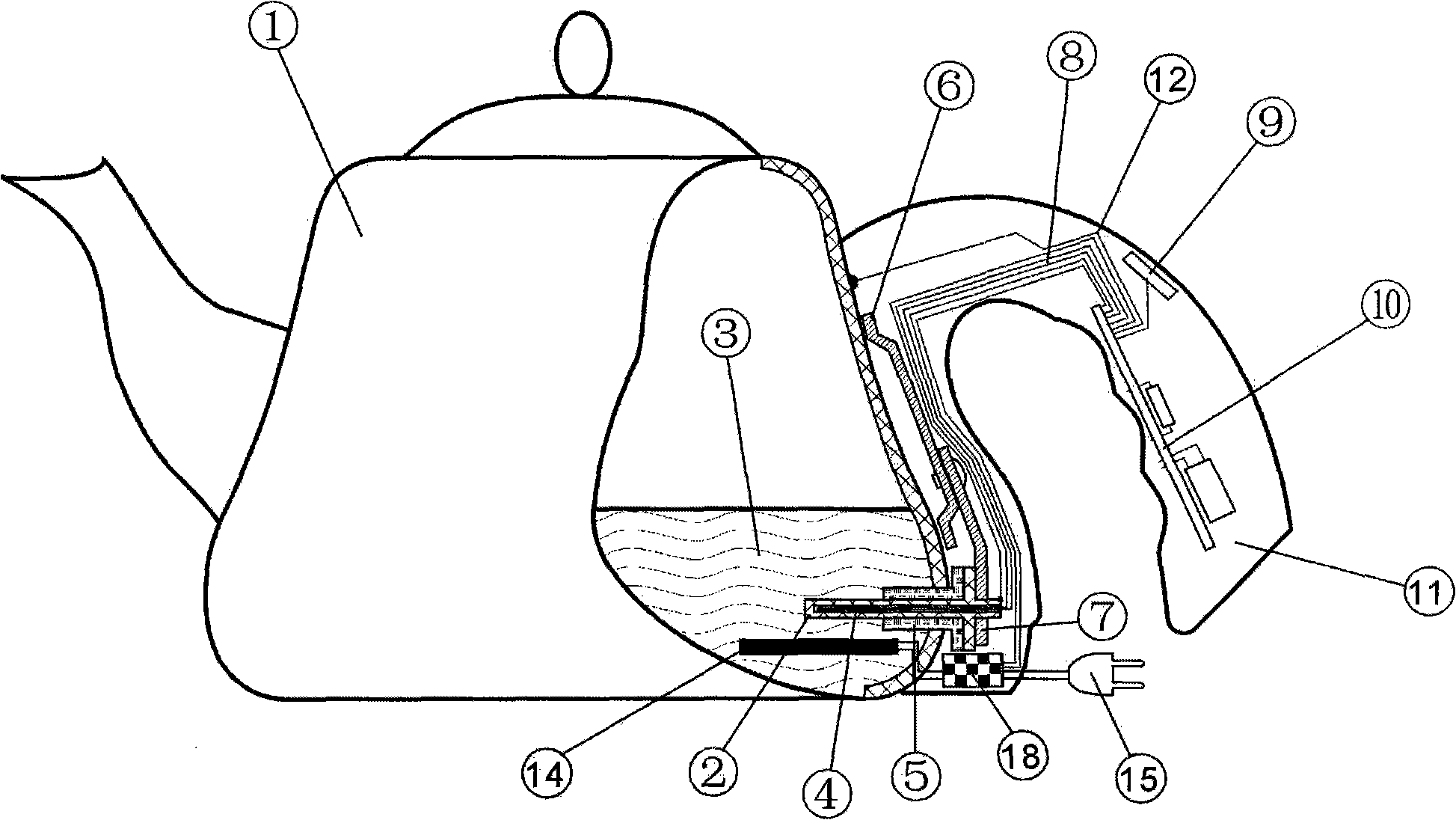

[0026] figure 2 A stainless steel boiling kettle with electric heating rods. It differs from Embodiment 1 in that the bottom of the inner cavity of the kettle body 1 is equipped with an electric heating rod 14 at the same time, and the power supply of the kettle control circuit 10 is obtained from the power line 15 of the electric heating rod 14 through the rectified power supply 18 obtained.

Embodiment 3

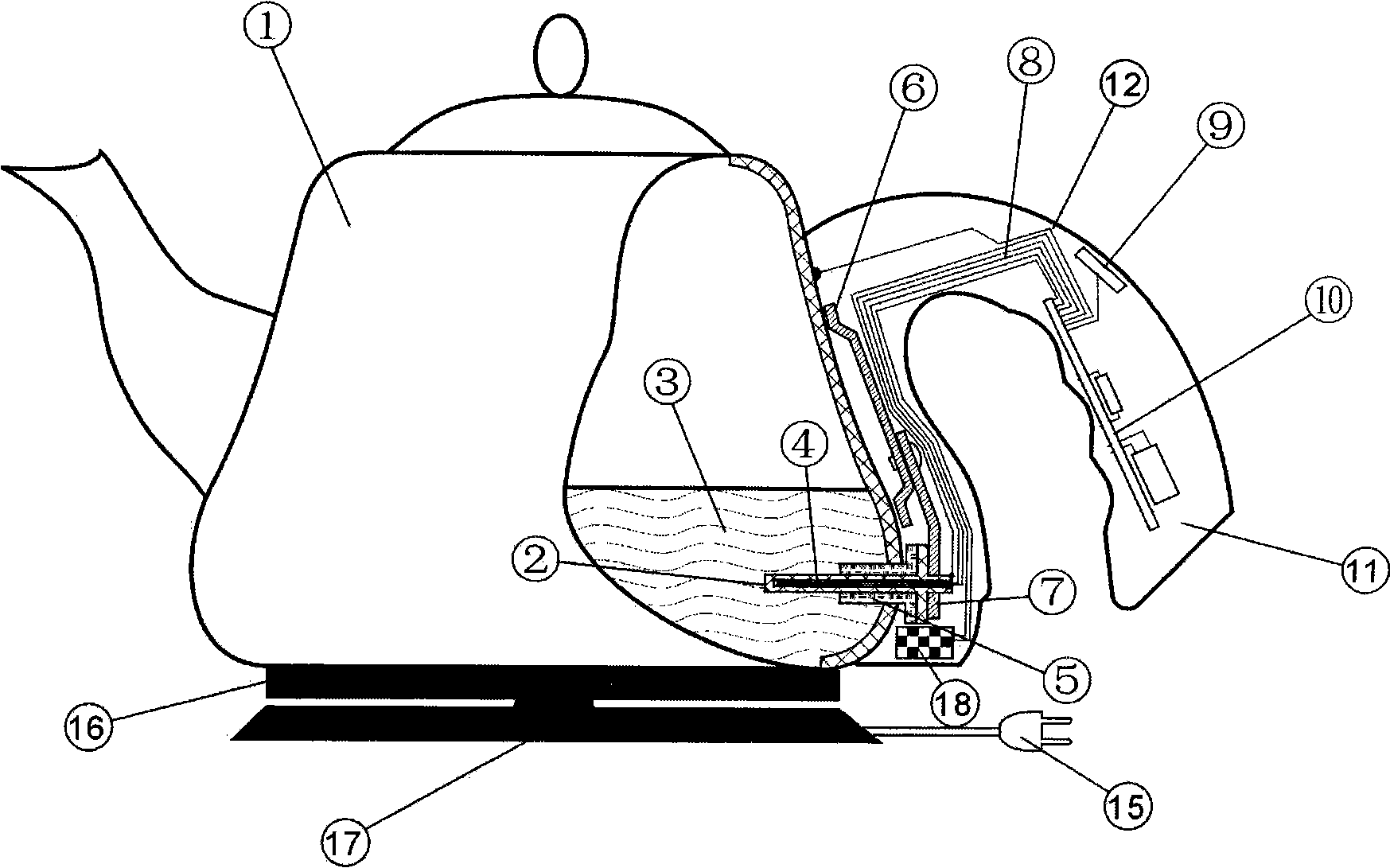

[0028] image 3 A kettle with an electric heating base. It differs from Embodiment 1 in that an electric heating body 16 and a corresponding power base 17 are installed at the bottom of the kettle body 1; The rectified power supply 18 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com