Process technique for burley tobacco in blend type cigarette

A hybrid cigarette and processing technology technology, applied in tobacco, tobacco preparation, application and other directions, can solve the problems of long water control response time, difficult to fully absorb material liquid, long processing time, etc. Accurate control, reducing equipment and land occupation investment, and improving the effect of enterprise economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

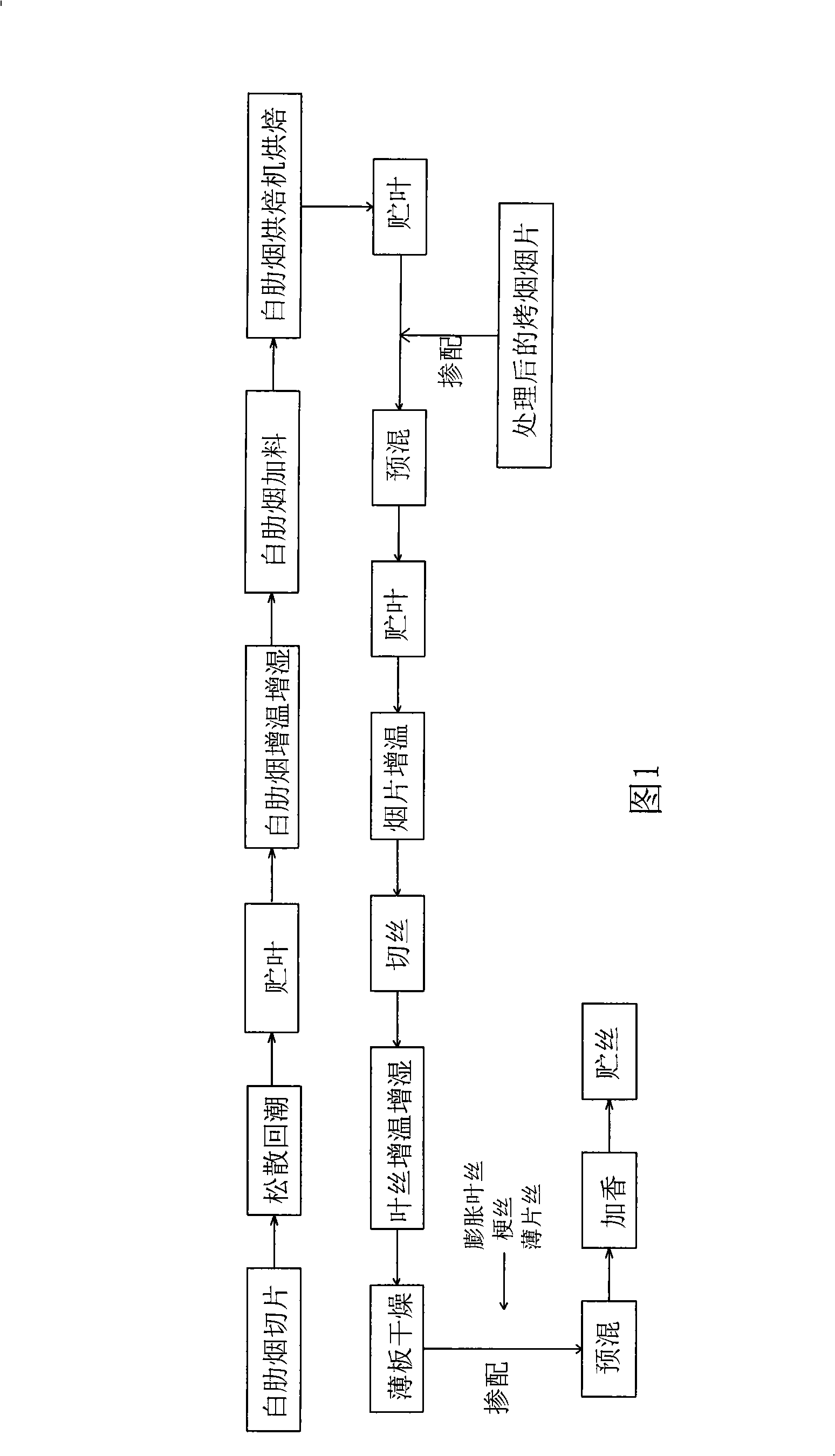

Method used

Image

Examples

Embodiment 1

[0037] Hubei Zhongsan Burley Tobacco Leaves 2000kg, its processing technology includes:

[0038] 1. The Burley tobacco blade workshop section, the specific process steps are: 1. Burley tobacco slices: the Burley tobacco slices are cut into several pieces; Wet, control the moisture content of the leaves at 15% to 17%, and control the temperature at 55°C to 65°C; ③Sieve and add materials to the loose Burley tobacco sheets, so that the moisture content of the leaves is controlled at 22% to 28% %, the leaf temperature is controlled at 50°C to 60°C, and the feed amount is 20% to 30% of the Burley tobacco material amount;

[0039] ④Transport the added Burley tobacco flakes to the storage cabinet for storage, the storage time is greater than or equal to 2 hours, blend the flakes with the feed liquid evenly and balance the moisture and feed liquid;

[0040]II Burley tobacco shredded plant section, the specific process steps are: ①The processed Burley tobacco slices are cut into shred...

Embodiment 2

[0043] 2,000kg of Chongqing Secondary Burley Tobacco Leaves, the processing techniques include:

[0044] 1. The Burley tobacco blade workshop section, the specific process steps are: 1. Burley tobacco slices: the Burley tobacco slices are cut into several pieces; Wet, control the moisture content of the leaves at 15% to 17%, and control the temperature at 55°C to 65°C; ③Sieve and add materials to the loose Burley tobacco sheets, so that the moisture content of the leaves is controlled at 22% to 28% %, the leaf temperature is controlled at 50°C-60°C, and the feeding amount is 20%-30% of the material volume of Burley tobacco; ④Transport the added Burley tobacco slices to the storage cabinet for storage, and the storage time is greater than or equal to 2 hours , mix the smoke sheet and the feed liquid evenly and balance the moisture and the feed liquid;

[0045] II Burley tobacco shredded plant section, the specific process steps are: ①The processed Burley tobacco slices are cut...

Embodiment 3

[0048] 2000kg of Hubei Zhonger 2 Burley tobacco leaves, the processing technology includes:

[0049] 1. The Burley tobacco blade workshop section, the specific process steps are: 1. Burley tobacco slices: the Burley tobacco slices are cut into several pieces; Wet, control the moisture content of the leaves at 15% to 17%, and control the temperature at 55°C to 65°C; ③Sieve and add materials to the loose Burley tobacco sheets, so that the moisture content of the leaves is controlled at 22% to 28% %, the leaf temperature is controlled at 50°C-60°C, and the feeding amount is 20%-30% of the material volume of Burley tobacco; ④Transport the added Burley tobacco slices to the storage cabinet for storage, and the storage time is greater than or equal to 2 hours , mix the smoke sheet and the feed liquid evenly and balance the moisture and the feed liquid;

[0050] II Burley tobacco shredded plant section, the specific process steps are: ①The processed Burley tobacco slices are cut int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com