Method for producing structure

A technology for components and supporting components, which can be used in photosensitive materials for opto-mechanical equipment, 3-dimensional image production, photoengraving of pattern surfaces, etc., and can solve problems such as difficult production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

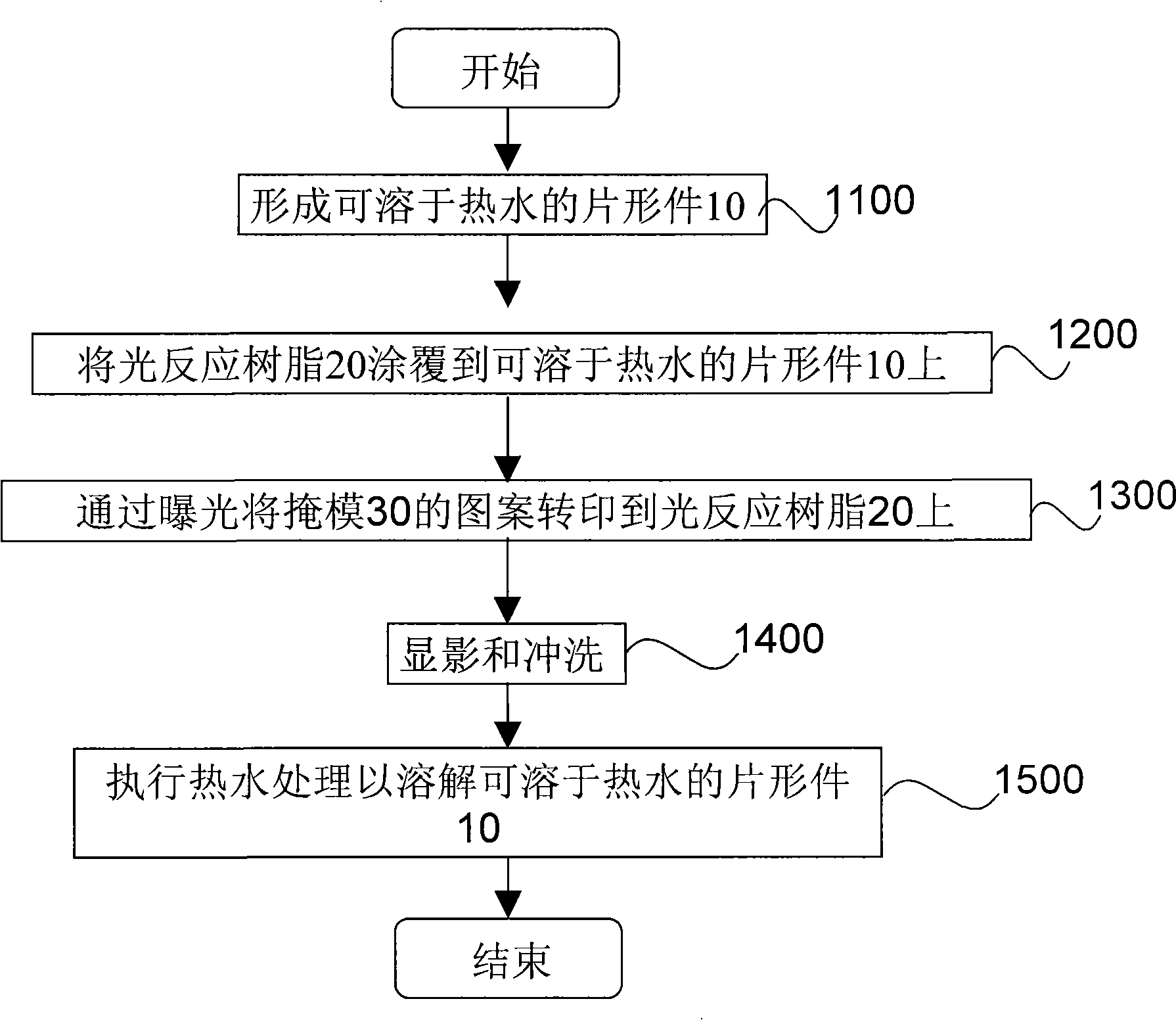

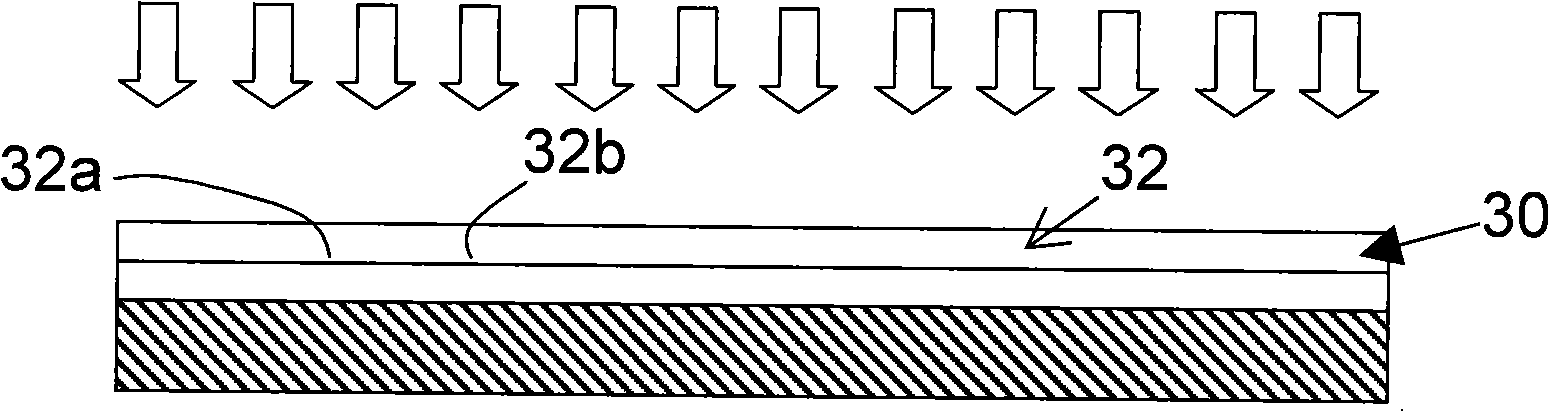

[0029] A method for fabricating a structure according to an embodiment of the present invention will be described below with reference to the accompanying drawings. figure 1 Steps in the fabrication method are shown.

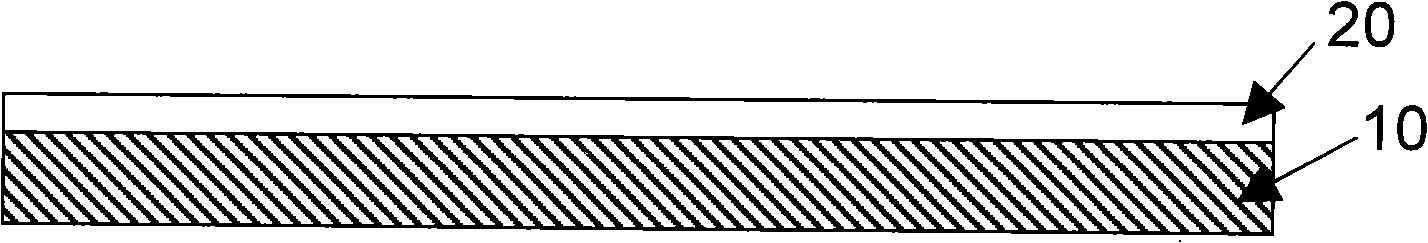

[0030] A hot water soluble sheet 10 is formed (step 1100). The hot water soluble sheet member 10 is a hot water soluble sheet member and is composed of agar or polyvinyl alcohol resin. These materials are also environmentally friendly. Agar is soluble in hot water at a temperature of about 50 degrees Celsius or higher. Polyvinyl alcohol resin is soluble in hot water at a temperature of about 80 degrees Celsius or higher. The size and shape of the hot water soluble sheet member 10 are not particularly limited.

[0031] The photoreactive resin 20 is coated on the hot water soluble sheet 10 (step 1200). Examples of photoreactive resins that can be used include, but are not limited to: polyvinylcinnamate, cyclized polyisoprene-bisazide, novolac resin, fluorocar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com