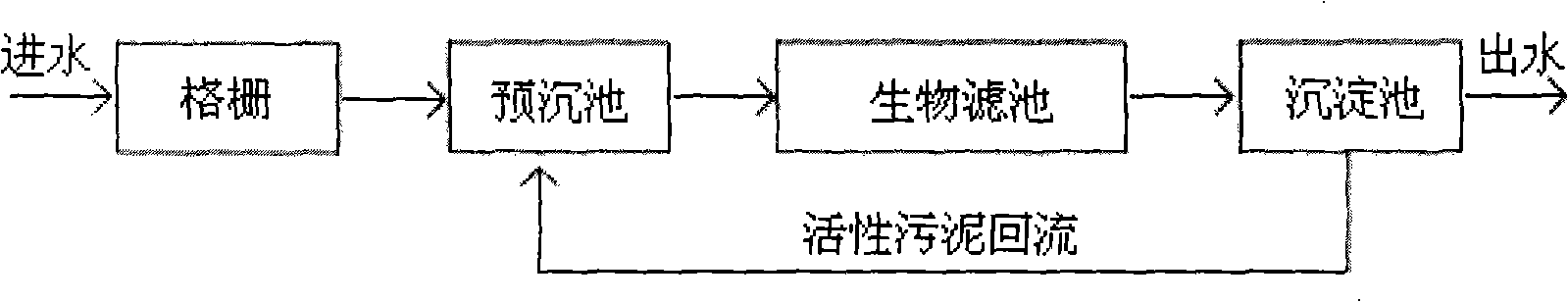

Elastic fiber biological filter technique for treating sewage

A technology of elastic fiber and biofilter, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problem of reducing hydraulic load and treatment efficiency, reducing the specific surface area of the infiltration medium, Urban applicability restrictions and other issues, to achieve the effect of reducing management and maintenance costs, strong pollutant retention capacity, and strong pollutant retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

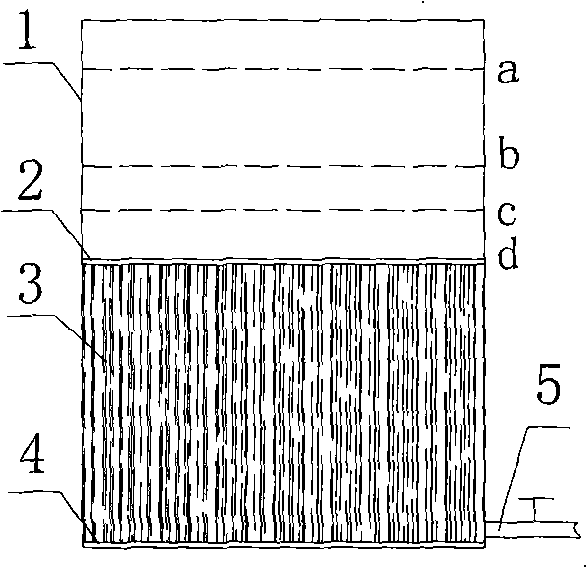

[0035] Embodiment 1: elastic fiber biofilter sewage treatment process, it comprises the steps:

[0036]1) Filling with elastic fiber: divide the elastic fiber 3 into bundles (in bundles, the size of each bundle is not required, as uniform as possible), the lower end of the elastic fiber is fixedly connected with the bottom plate 4 (the bottom plate is covered with permeable holes), The upper end of the elastic fiber is fixedly connected with the top plate 2 covered with water inlet holes 6, and then the bottom plate 4, the elastic fiber 3, and the top plate 2 are filled in the open biofilter 1, the bottom plate is fixedly connected with the biofilter, and the top plate is connected with the biofilter. The lifting device is connected; the natural extension length of the elastic fiber is 90% of the height of the biofilter; the upper end of the biofilter is provided with a water inlet, which is located above the top plate, and the lower end of the biofilter is provided with a wate...

Embodiment 2

[0059] Elastic fiber biofilter sewage treatment process, it comprises the following steps:

[0060] 1) Filling with elastic fibers: divide the elastic fibers into bundles (in bundles, the size of each bundle is not required, as uniform as possible), the lower end of the elastic fibers is fixedly connected with the bottom plate (the bottom plate is covered with permeable holes), and the elastic fibers The upper end of the upper end is fixedly connected with the top plate covered with water inlet holes, and then the bottom plate, elastic fiber and top plate are filled in the open biofilter, the bottom plate is fixedly connected with the biofilter, and the top plate is connected with the lifting device; the elastic fiber is naturally The extension length is 50% of the height of the biofilter; the upper end of the biofilter is provided with a water inlet, the water inlet is located above the top plate, and the lower end of the biofilter is provided with a water outlet (the water ou...

Embodiment 3

[0066] Embodiment 3: elastic fiber biofilter sewage treatment process, it comprises the steps:

[0067] 1) Filling with elastic fibers: divide the elastic fibers into bundles (in bundles, the size of each bundle is not required, as uniform as possible), the lower end of the elastic fibers is fixedly connected with the bottom plate (the bottom plate is covered with permeable holes), and the elastic fibers The upper end of the upper end is fixedly connected with the top plate covered with water inlet holes, and then the bottom plate, elastic fiber and top plate are filled in the open biofilter, the bottom plate is fixedly connected with the biofilter, and the top plate is connected with the lifting device; the elastic fiber is naturally The stretching length is 90% of the height of the biofilter; the upper end of the biofilter is provided with a water inlet, the water inlet is located above the top plate, and the lower end of the biofilter is provided with a water outlet (the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com