The application of erucamide in pharmaceuticals

An erucamide and drug technology, applied in the application field as an anti-sticking agent, can solve the problems of melting, uneven drying and wetness of particles, roughness, etc., and achieve the effect of solving the problem of sticking and punching, the surface is complete and smooth, and the machine of preventing sticking and punching is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] No erucamide was added, and the original formula was tested. The ingredients of the formula are as follows:

[0033] Aminophylline 75g

[0034] Bromhexine Hydrochloride 15g

[0035] Chlorpheniramine Maleate 1.5g

[0036] Ethanol 17ml (95%)

[0037] Disodium hydrogen phosphate 3.6g

[0039] Starch 29.4g

[0040] Magnesium stearate 1.2g

[0041] Hypromellose 6g

[0042] Sodium starch glycolate 2g

[0044] 1000 pieces (0.14g / piece)

[0045] The production process of tea cinnamin tablets:

[0046] (1) Prepare materials according to the above prescription, add chlorpheniramine maleate into 95% ethanol, stir until completely dissolved, add 2 / 3 of the recipe amount of starch and stir evenly, dry below 50°C, pass through a 80-mesh sieve, and set aside .

[0047] (2) Pulping: Dissolve disodium hydrogen phosphate in an appropriate amount of pure water and pour it into the pulping starch, add an appropriate amount of...

Embodiment 2

[0064] Remove the addition of lubricant talcum powder and magnesium stearate in the original formula, add erucamide 0.8g in the mixture, and the formula table is as follows:

[0065] Aminophylline 75g

[0066] Bromhexine Hydrochloride 15g

[0067] Chlorpheniramine Maleate 1.5g

[0068] Ethanol 17ml (95%)

[0069] Disodium hydrogen phosphate 3.6g

[0070] Starch 29.4g

[0071] Hypromellose 6g

[0072] Sodium starch glycolate 2g

[0073] Starch slurry 3.6g

[0074] Erucamide 0.8g

[0075] 1000 pieces (0.12g / piece)

[0076] The production process of tea pheniramine tablets: (1) prepare materials according to the above formula, add chlorpheniramine maleate to 95% ethanol, stir until fully dissolved, add 2 / 3 of the prescription amount of starch and stir evenly, 50 ℃ Dry the following, pass through 80 mesh sieves, and set aside.

[0077] (2) Pulping: Dissolve disodium hydrogen phosphate in an appropriate amount of pure water and pour it into the pulping starch, add an appr...

Embodiment 3

[0085] Remove the addition of lubricant talcum powder and magnesium stearate in the original formula, add erucamide 1.0g in the mixture, and the formula table is as follows:

[0086] Aminophylline 75g

[0087] Bromhexine Hydrochloride 15g

[0088] Chlorpheniramine Maleate 1.5g

[0089] Ethanol 17ml (95%)

[0090] Disodium hydrogen phosphate 3.6g

[0091] Starch 29.4g

[0092] Hypromellose 6g

[0093] Sodium starch glycolate 2g

[0094] Starch slurry 3.6g

[0095] Erucamide 1.0g

[0096] 1000 pieces (0.12g / piece)

[0097] Production technology is with embodiment 2.

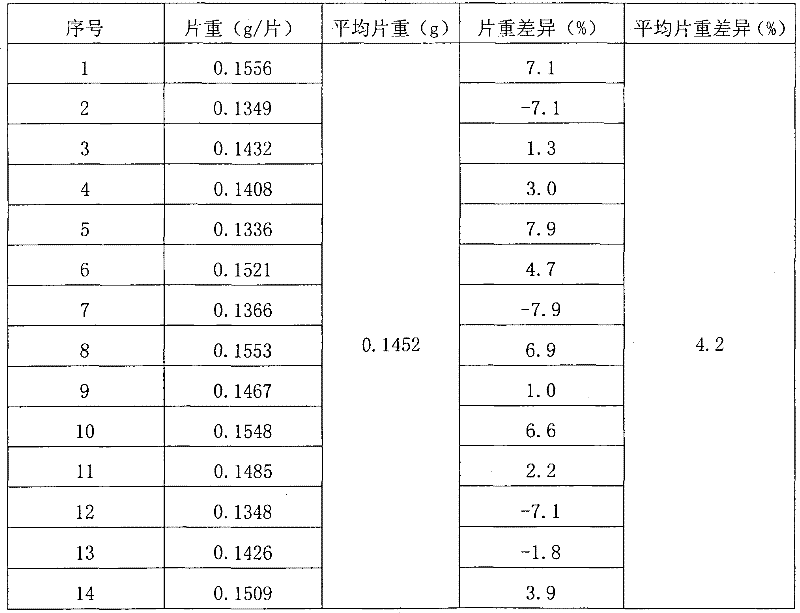

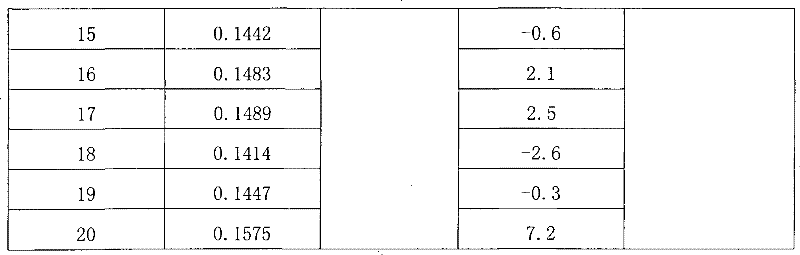

[0098] According to the method of Example 1, 20 tablets of C batch of medicines were seized, and the measured average tablet weight was 0.1261g / sheet, and the quality inspection results were shown in the following table:

[0099]

[0100] According to the analysis of the results, among the 20 tablets of Batch C randomly selected and inspected, the appearance of the tablets was consistent, the surface w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com