Probe assembly, device for lapping bar and method for lapping bar

A combination and probe technology, applied in the field of probe combination, can solve the problems of easy bending, difficult positioning, excessive pressing force, etc., and achieve short preparation time, less influence of electrostatic damage or pollution, and easy positioning operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

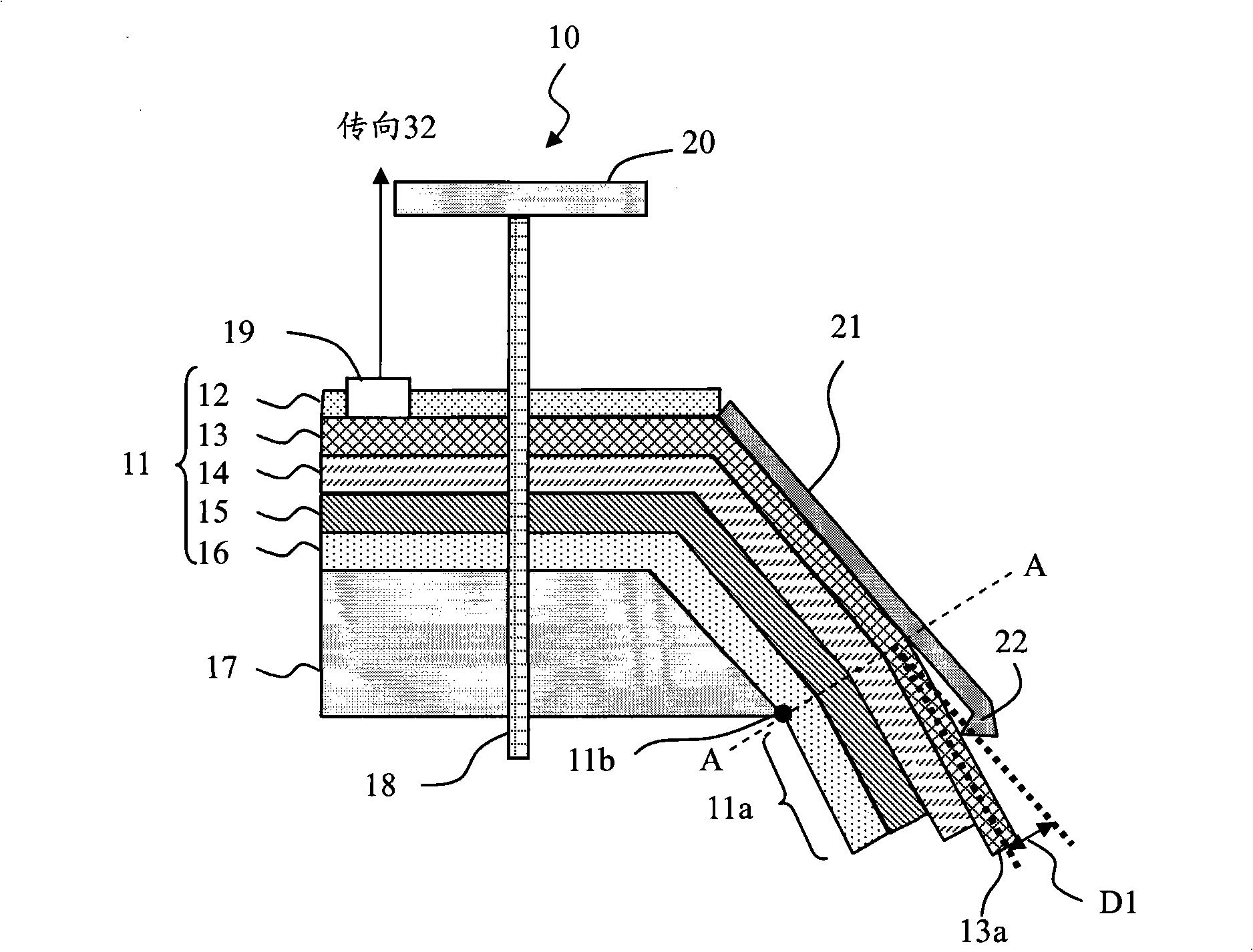

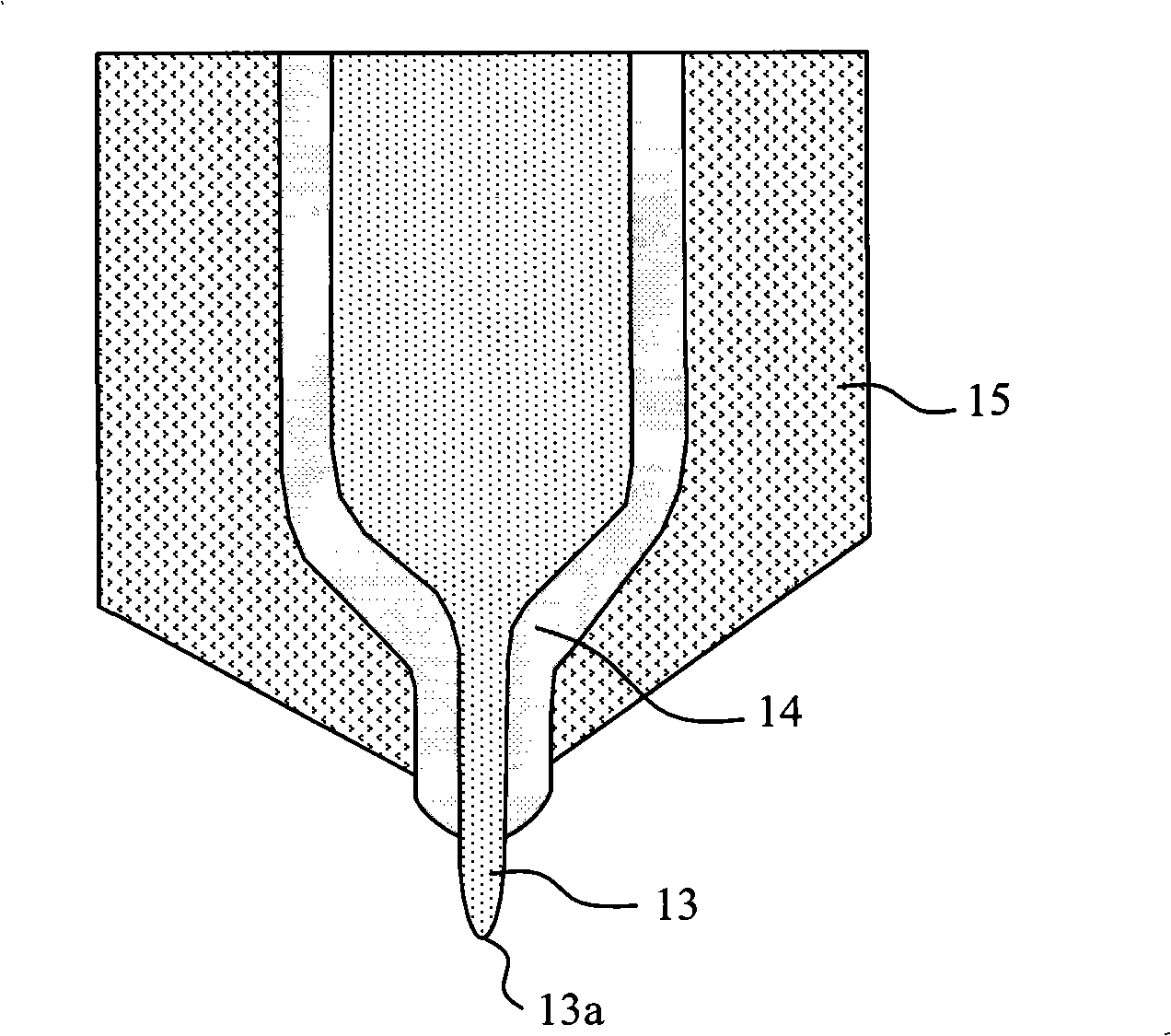

[0021] Hereinafter, the probe assembly according to the present invention and the elongated polishing apparatus using the probe assembly will be described in detail with reference to the drawings.

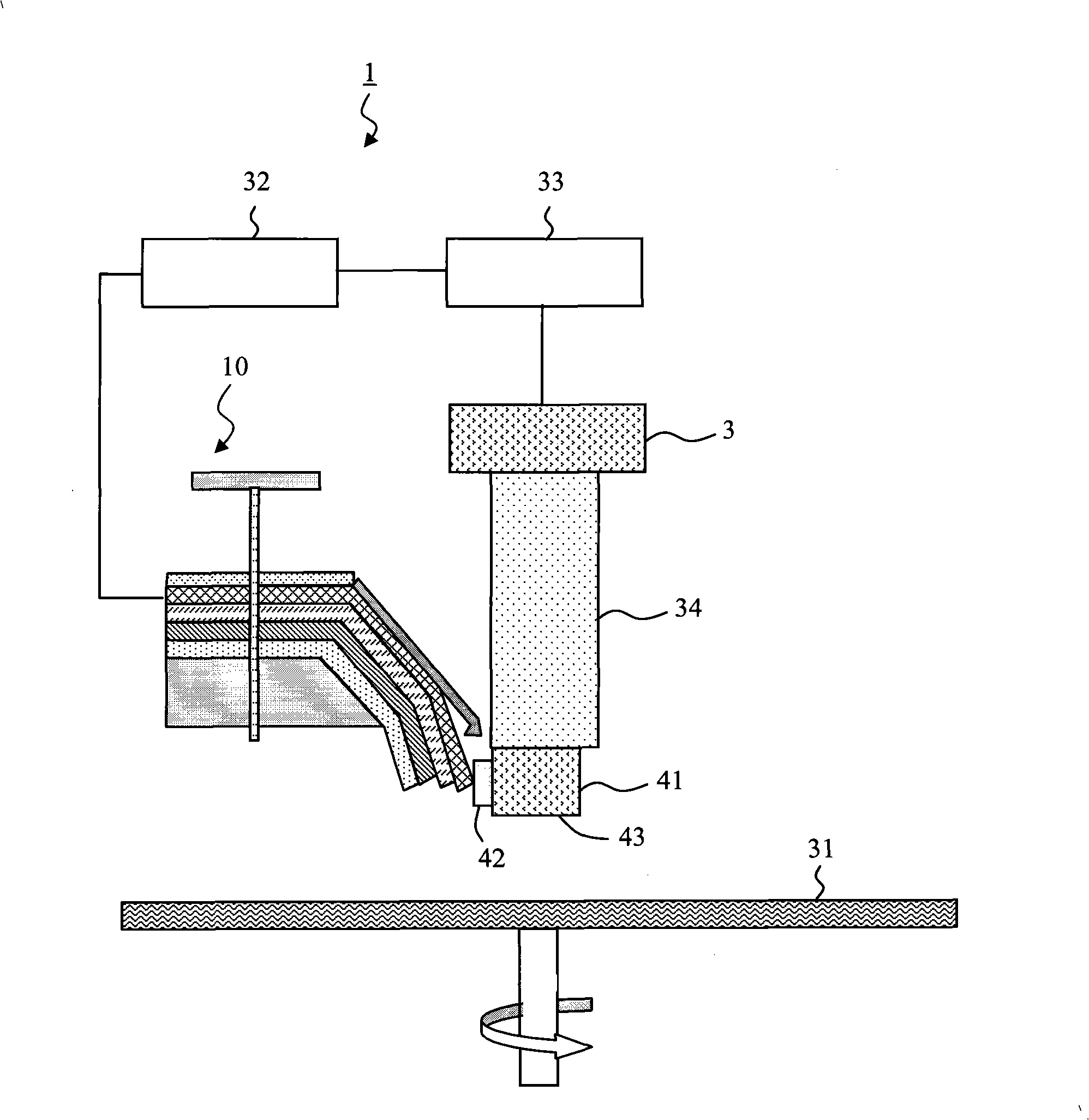

[0022] figure 1 It is an outline diagram of the composition of the elongate grinding device according to the first embodiment of the present invention. The grinding device 1 includes a probe assembly 10 , a rotatable grinding table 31 , a control device 33 electrically connected to the probe assembly 10 through a relay measurement substrate 32 , and a fixing device 34 supporting the elongated bar 41 .

[0023] The elongated bar 41 is installed on the fixing device 34 , and the grinding surface 43 is opposite to the grinding table 31 . When grinding the grinding surface 43 of the elongated bar 41 , the elongated bar 41 is pressed onto the grinding table 31 . Here, the bar 41 is an elongated element cut out from a wafer, and is a laminate in which a plurality of elements to be a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com