A method for aligning screw bearing seat

A technology of bearing seat and lead screw, which is applied in the maintenance field of lead screw, can solve the problems of long preparation period, large impact of dial indicator, high labor intensity, etc., and achieve the effect of increasing maintenance cost, increasing preparation time and increasing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

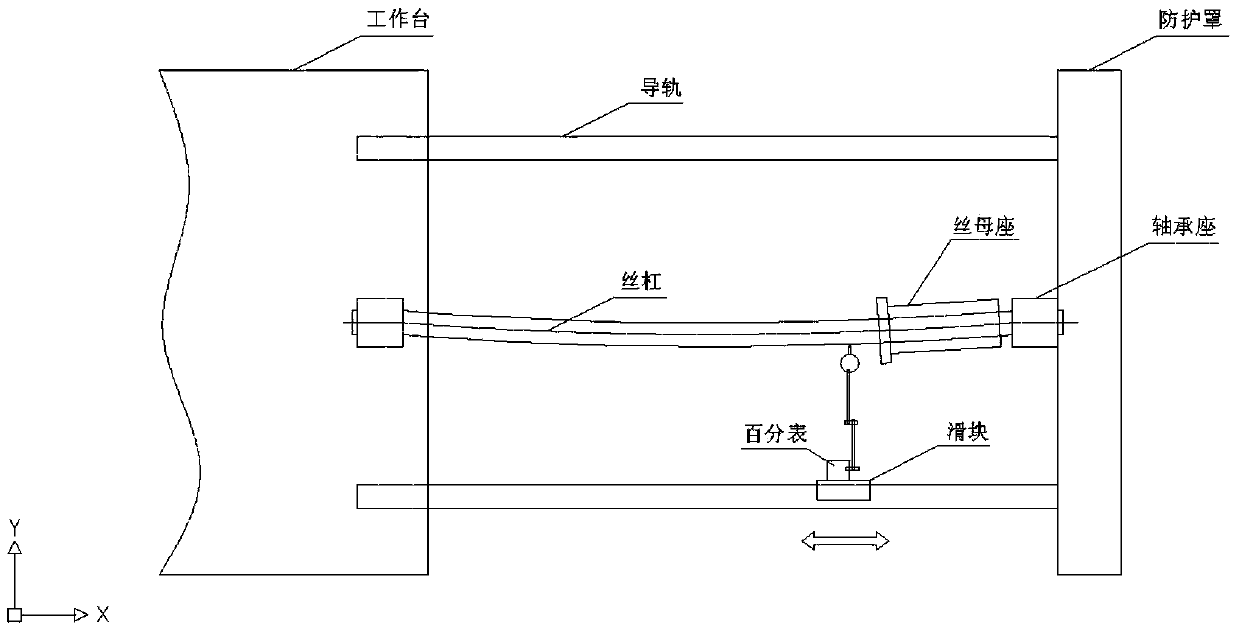

[0044] To detect the lead screw in the X direction of a certain machine tool, place the dial indicator frame on the machine tool table near the screw nut seat, and press the shift pointer of the dial indicator on the straight surface of the lead screw.

[0045] Start the machine tool to move the workbench from the left end to the right end close to the bearing seat, and record the readings of the hands.

[0046] It is found that there are errors in both the horizontal plane and the vertical plane of the right-hand screw socket, the position error of the horizontal plane is 0.3MM, and the position error of the vertical plane is 0.1MM.

[0047] To adjust the horizontal direction, attach the dial indicator frame to the bed, and the needle of the dial indicator touches the surface of the nut seat to be adjusted; loosen the fastening screw of the right end bearing seat with error, and adjust 0.3MM in the opposite direction with a jack before tightening it. solid.

[0048] The adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com