Quick testing tool for machining dimension of complicated casting and testing method thereof

A technology for processing dimensions and inspecting tooling, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of incomplete inspection and single structure of technical solutions, and achieve the effects of improving efficiency, convenient operation, and excellent use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The invention discloses a complex casting processing size rapid detection tool and a detection method suitable for the inspection of casting welding groove contours and space dimensions.

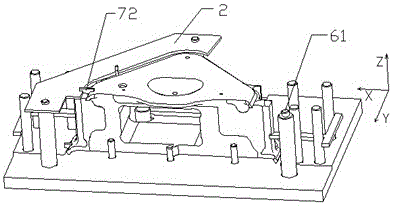

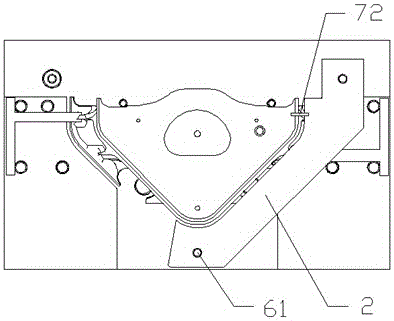

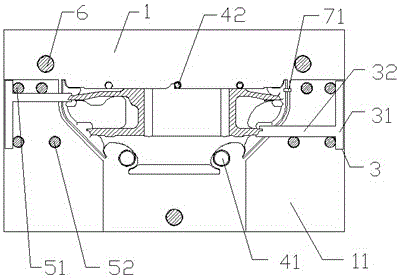

[0046] Such as Figure 1~Figure 3 As shown, a tool for rapid detection of complex casting processing dimensions includes a detection platform 1, and also includes a reference positioning assembly for casting reference positioning, a lateral positioning assembly for positioning during casting lateral detection, and a casting upper end surface. The pin assembly supported during the detection process and the detection measuring tool used for casting edge groove detection, the reference positioning assembly, the lateral positioning assembly and the pin assembly are all fixedly arranged on the detection platform 1;

[0047] The lower end surface detection boss 11 is fixedly arranged on the detection platform 1, the edge profile of the lower end surface detection boss 11 matches the outline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com