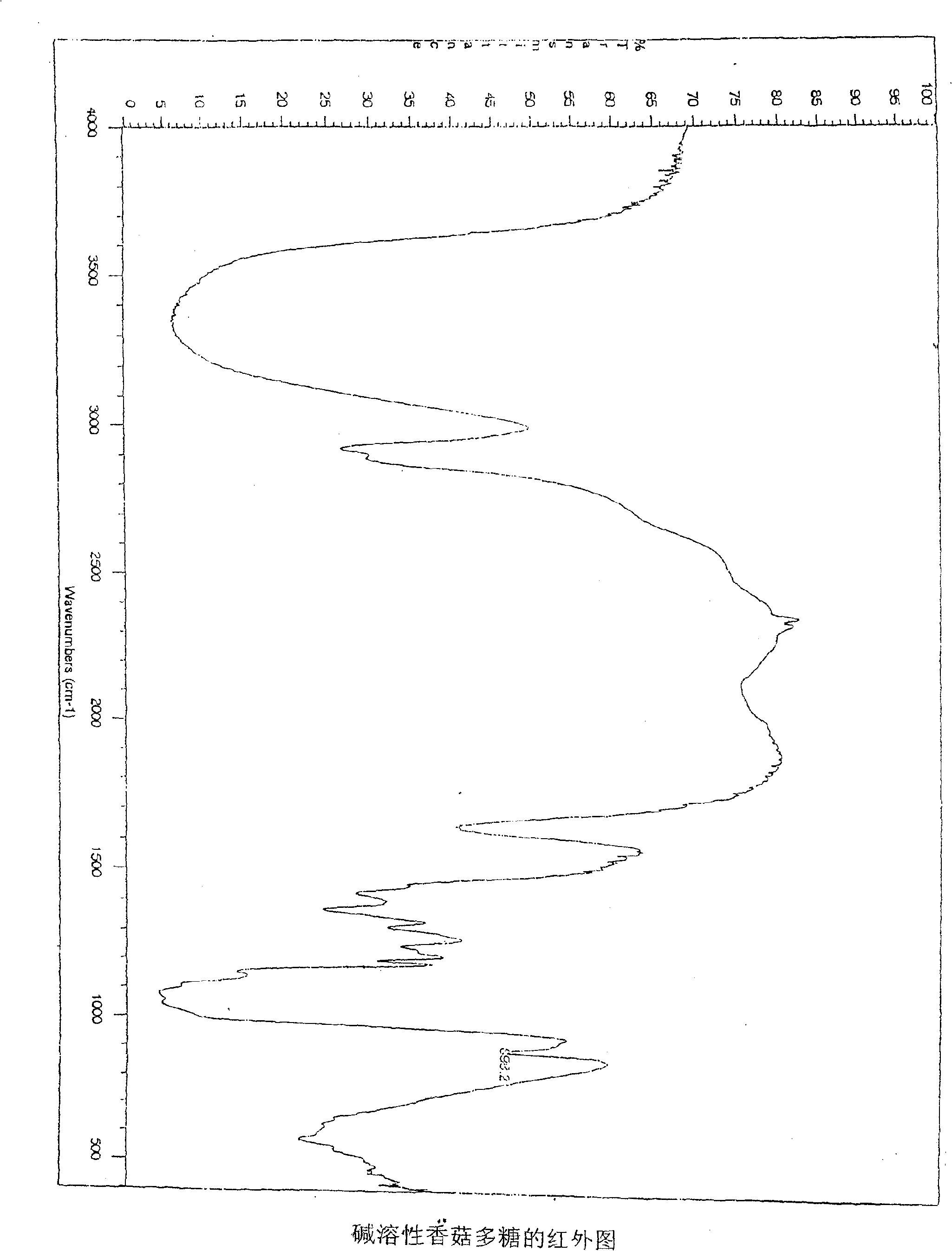

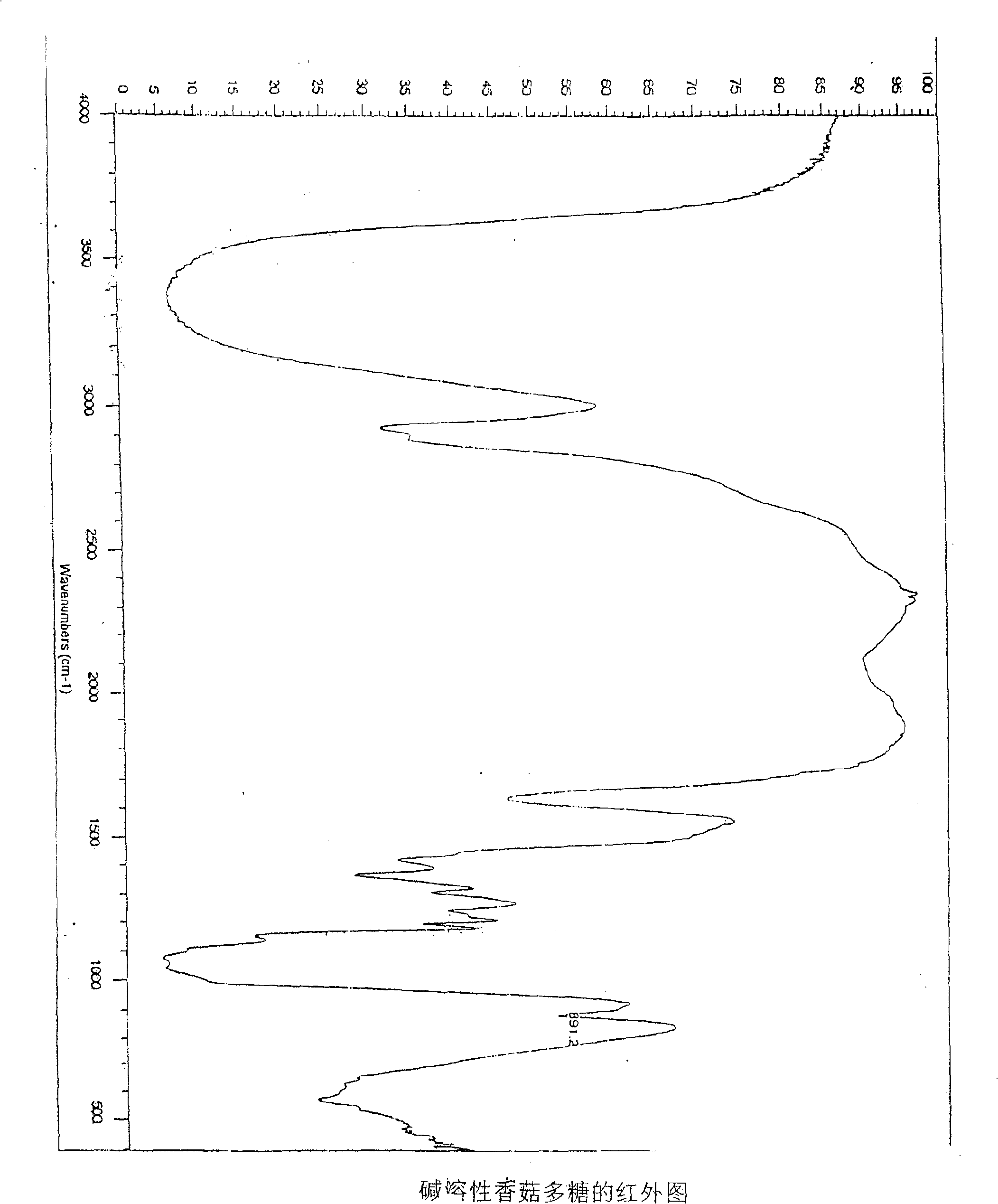

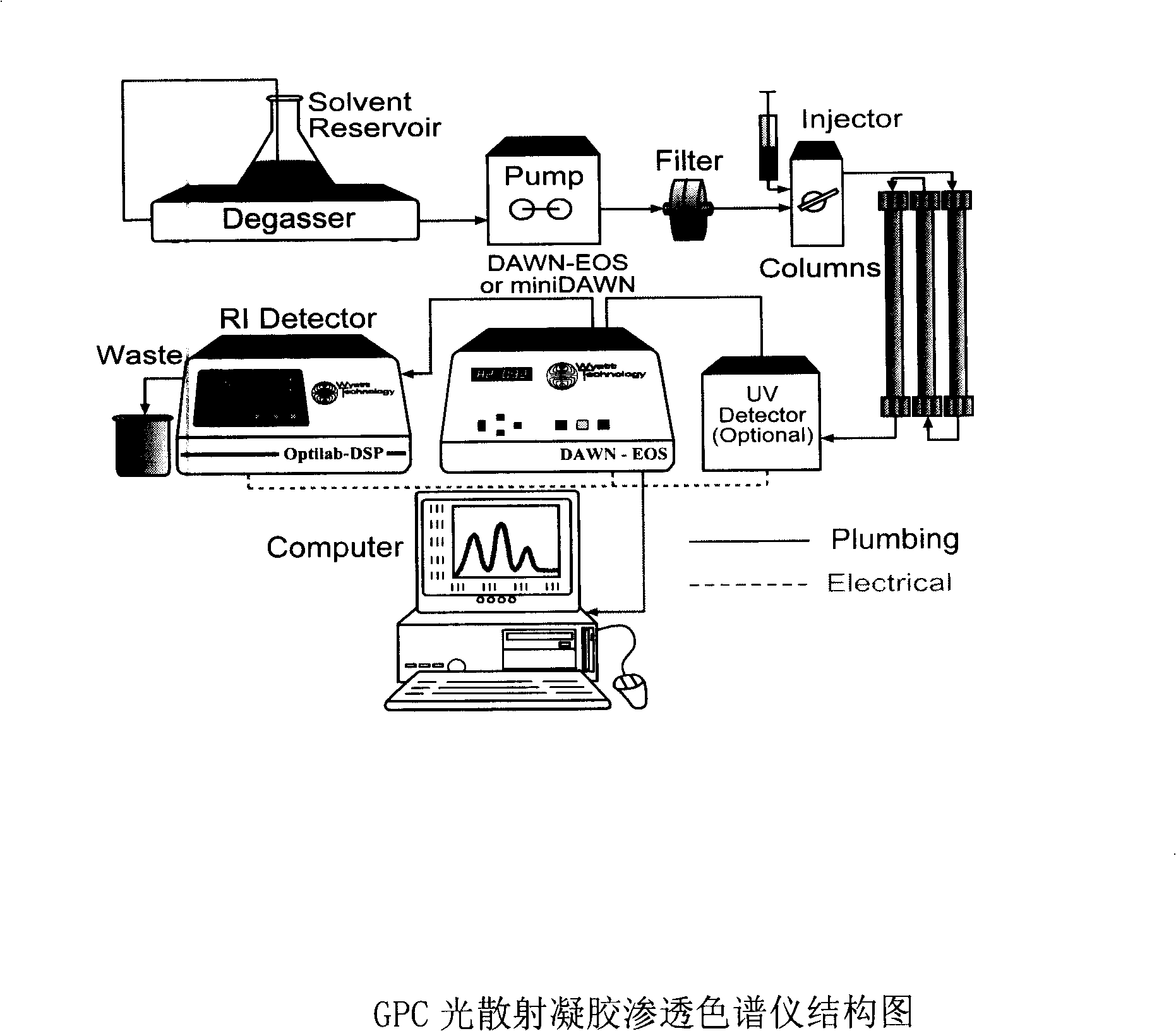

Alkaline soluble lentinan extraction, separation, purification and molecular weight determination

A technology of lentinan and molecular weight, which is applied in the field of new purification process and molecular weight determination, separation, and extraction of alkali-soluble lentinan, can solve the problems such as inability to accurately judge whether the raw material of lentinan is qualified or not, large error in molecular weight measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Take 8 kg of qualified dry shiitake mushroom raw materials, crush them, and place them in a jacketed reaction pot. Add 80 kg of 0.5 mol / L NaoH alkali solution and heat to 40°C, keep stirring for 4 hours, filter, and extract the residue twice by the above method. Combine all the solutions, concentrate to one-tenth of the original volume, then add 0.3mol / L NaOH 2 times the lye of the concentrated solution to concentrate and wash twice, then use the same volume of deionized water to concentrate and wash twice, and the concentrated solution after washing The solution was detected by ninhydrin and the reaction did not show blue-purple. Use 50-70% ethanol to fractionate the washed concentrated solution under rapid stirring, continue to stir for 15 minutes and then stand still for 4 hours, the precipitation occurs, and the supernatant is poured out, and the precipitate is then washed with 80-90% ethanol After dissolving and stirring for 15 minutes, stand still for 4 hours, a ...

Embodiment 2

[0014] Take 10 kg of qualified dried shiitake mushroom raw materials, crush them, and place them in a jacketed reaction pot. Add 100 kg of 0.5mol / LnaoH alkali solution and heat to 40°C, keep stirring for 4 hours, filter, and extract the residue twice by the above method. Combine all the solutions, concentrate to one-tenth of the original volume, then add 0.3mol / L NaOH 2 times the lye of the concentrated solution to concentrate and wash twice, then use the same volume of deionized water to concentrate and wash twice, and the concentrated solution after washing The solution was detected by ninhydrin and the reaction did not show blue-purple. Use 50-70% ethanol to fractionate the washed concentrated solution under rapid stirring, continue to stir for 15 minutes and then stand still for 4 hours, the precipitation occurs, and the supernatant is poured out, and the precipitate is then washed with 80-90% ethanol After dissolving and stirring for 15 minutes, stand still for 4 hours, ...

Embodiment 3

[0017] Take 13 kilograms of qualified dried shiitake mushroom raw materials, crush them, and place them in a jacketed reaction pot. Add 130 kg of 0.5 mol / L naoH alkali solution and heat to 40°C, keep stirring for 4 hours, filter, and extract the residue twice by the above method. Combine all the solutions, concentrate to one-tenth of the original volume, then add 0.3mol / L NaOH 2 times the lye of the concentrated solution to concentrate and wash twice, then use the same volume of deionized water to concentrate and wash twice, and the concentrated solution after washing The solution was detected by ninhydrin and the reaction did not show blue-purple. Use 50-70% ethanol to fractionate the washed concentrated solution under rapid stirring, continue to stir for 15 minutes and then stand still for 4 hours, the precipitation occurs, and the supernatant is poured out, and the precipitate is then washed with 80-90% ethanol After dissolving and stirring for 15 minutes, it was left to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com