Network frame prefabricated composite board, sandwiched floor and its connection construction method

A construction method and composite board technology, applied in the direction of floor slabs, building materials, building components, etc., can solve the problems of flooding of manual wire inserts, cracking of surface plastering, disturbing the normal order, etc., so as to achieve low cost and improve sound insulation and heat preservation. Performance, the effect of simplifying the template

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

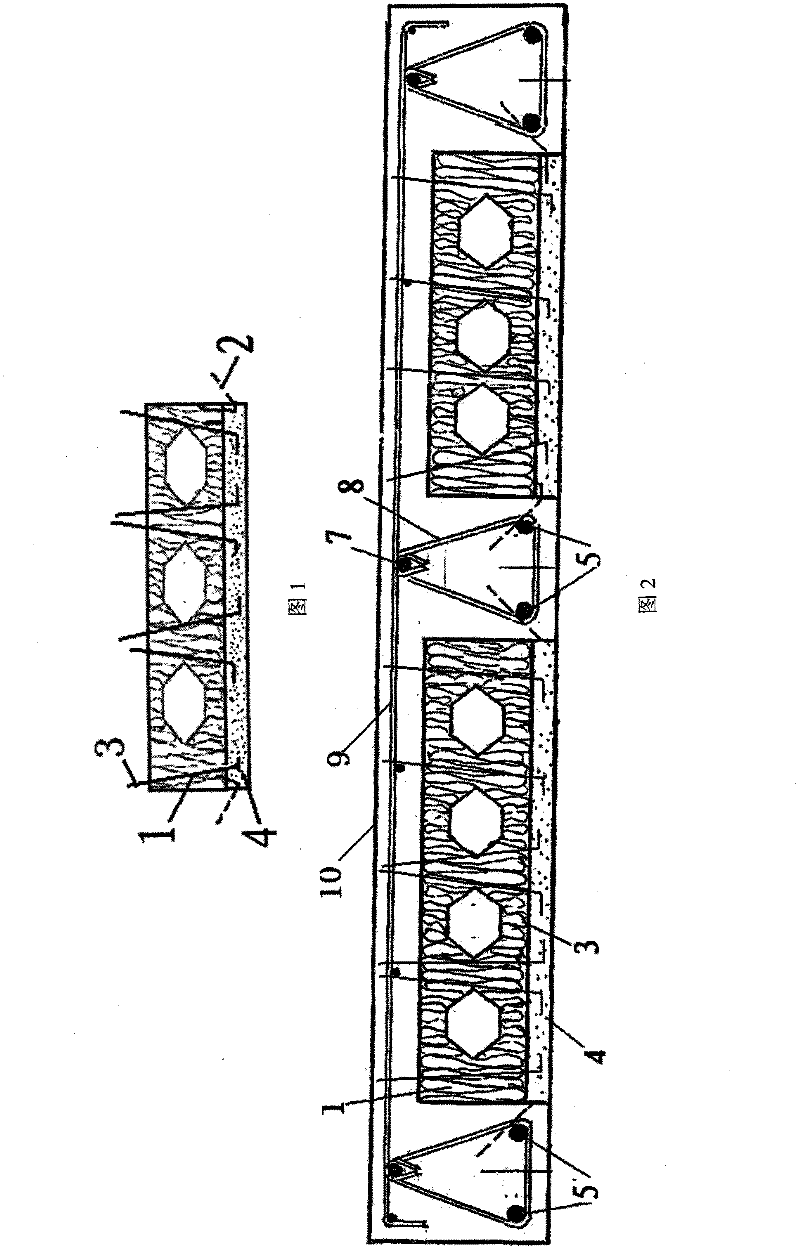

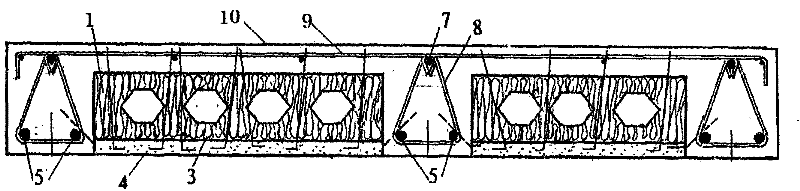

[0023] A kind of grid prefabricated composite board reference of this embodiment figure 1 , 2, including core board 1, core board 1 adopts EPS board with good heat insulation effect, and the bottom surface of core board 1 is connected with crisscross The steel wire is welded to form the steel wire mesh 2, and the steel wire mesh 2 and the core plate 1 are provided The oblique inserting ribs 3 are connected. The oblique inserting ribs 3 are evenly spaced and in different directions. One end is inserted into the core plate 1 obliquely and the end is 3-4cm, and the other end is welded with criss-crossed steel wires on the steel mesh 2; In between, the steel mesh 2 is covered by pouring to form a reinforced cement layer 4. The steel mesh 2 is longer than the core board 1, and the excess part extends out of the core board 1 to connect with other parts;

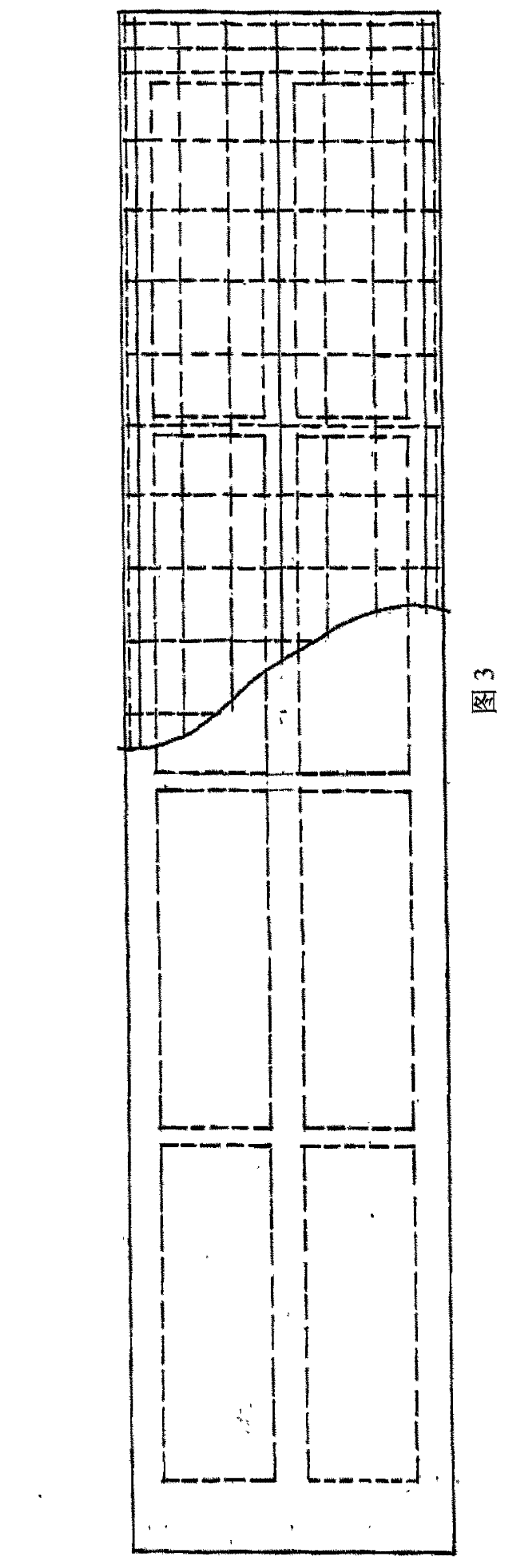

[0024] The sandwich floor slab adopting the above-mentioned grid prefabricated composite panel includes mutually spaced grid prefabr...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is:

[0033] The grid prefabricated composite panel sandwich floor slab is also laid between the grid prefabricated composite panel and the steel wire mesh 9 for fixing The steel mesh 6, the steel mesh 6 and the core plate 1 are provided with oblique inserts for connection, so that the core plate 1 and the upper steel mesh 6 are connected and fixed together, and then the upper part of the core plate 1 is poured to form a network frame Prefabricated composite panel sandwich composite floor.

[0034] The grid prefabricated composite board sandwich floor slab and its connection construction method of the above embodiments of the present invention adopts the grid prefabricated composite board composite with reinforced cement layer 4, which is cast-in-place at one time, has large bearing capacity, small dead weight, earthquake and fire resistance Good performance, reduce the amount of concrete and ceiling construction, simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com