Method for preparing long storage life liquid state egg

A technology of liquid egg and shelf life, applied in an application field of lysozyme, which can solve the problems of product quality decline, short shelf life of liquid eggs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0006] Specific Embodiment 1: The preparation method of liquid eggs with a long storage period in this embodiment is as follows: adding lysozyme and synergistic substances to egg liquid, and then pasteurizing to obtain liquid egg products, wherein the added amount of lysozyme It is 0.03%-0.25% of the total mass of the liquid egg, the added amount of the synergist is 0.1%-1.0% of the total mass of the liquid egg, and the activity of lysozyme is 8000U / mg-20000U / mg.

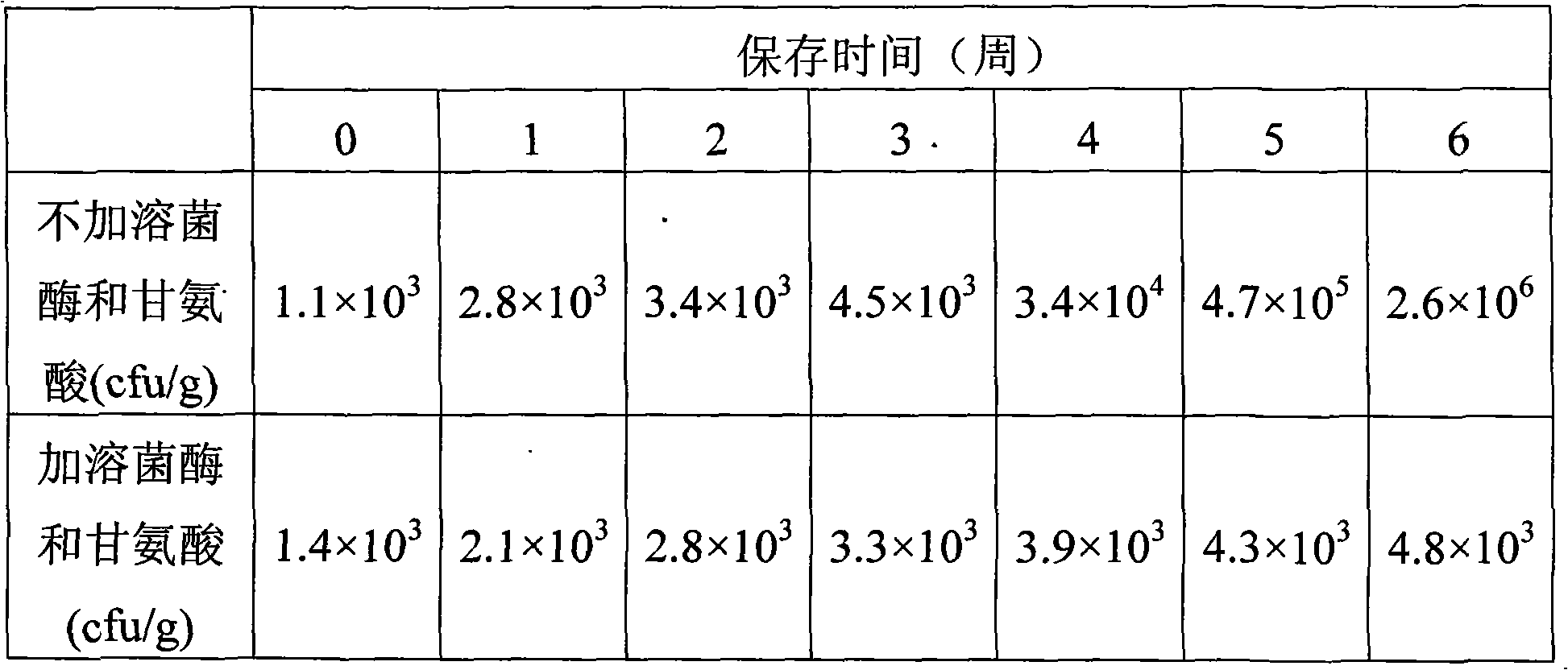

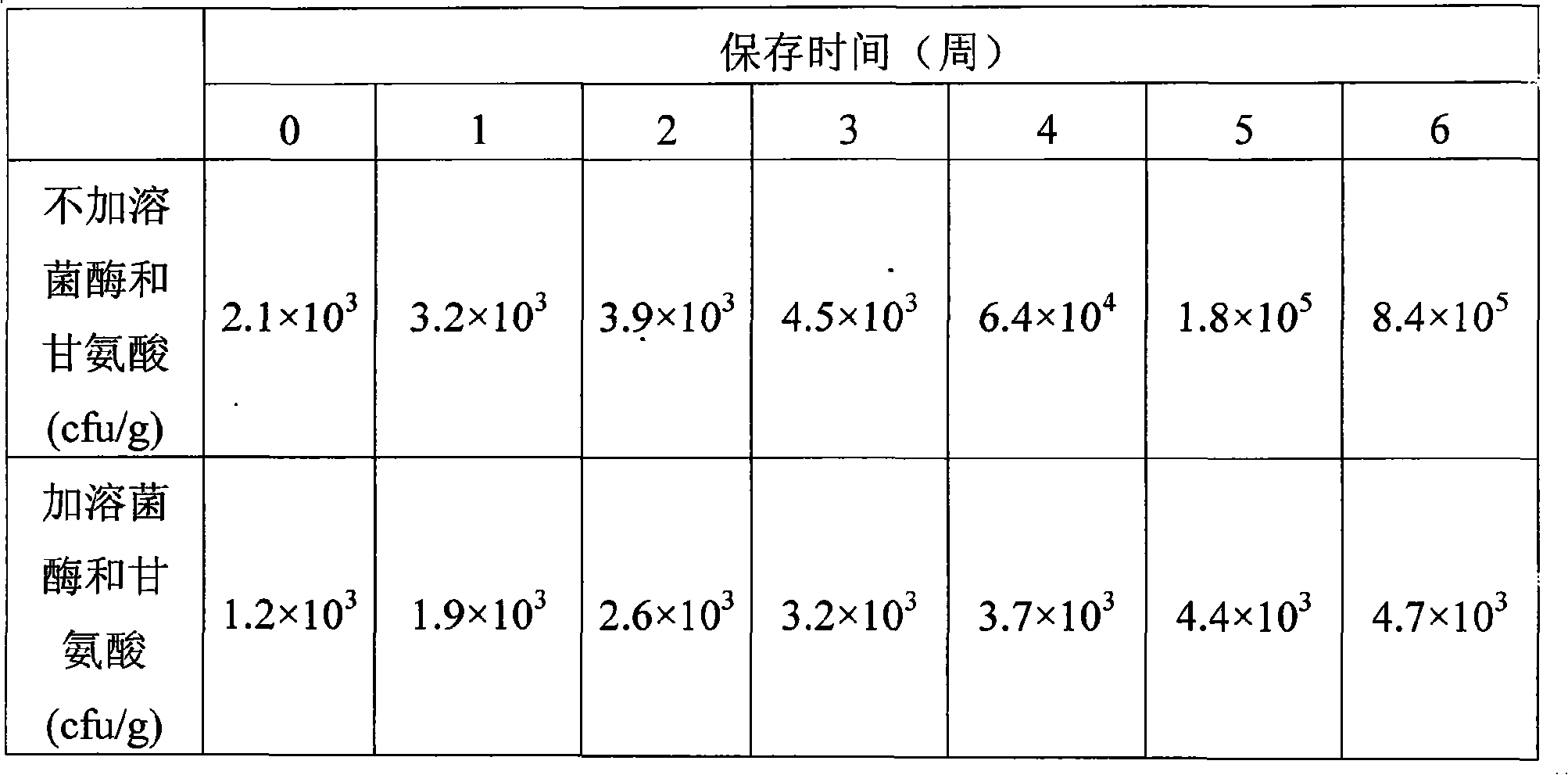

[0007] In this embodiment, 2.5 kg of lysozyme with an activity of 20,000 U / mg and 5 kg of glycine are added to 5 tons of whole egg liquid produced according to a conventional process, then pasteurized, and finally the whole egg liquid is divided into packages. The prepared whole egg liquid was stored under refrigerated conditions at 0-4°C, and the changes of the total number of bacteria in the whole egg liquid during storage are shown in Table 1.

[0008] Table 1

[0009]

[0010] It can be seen from Table 1 tha...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the liquid egg used is albumen liquid, egg yolk liquid or whole egg liquid. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 1 in that the synergist used is glycine. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total number of bacteria | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com